Heating Method of Partial Combustion Chamber of Coke Oven by Replacing Coal Gas

A gas heating and coke oven gas technology, which is applied in the heating of coke ovens, coke ovens, and combustible gas heating coke ovens, etc., can solve the problems of coke oven gas heating standpipe blockage, shortened coke oven life, and the need for more personnel. Achieve the effects of preventing gas poisoning accidents, heating up, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

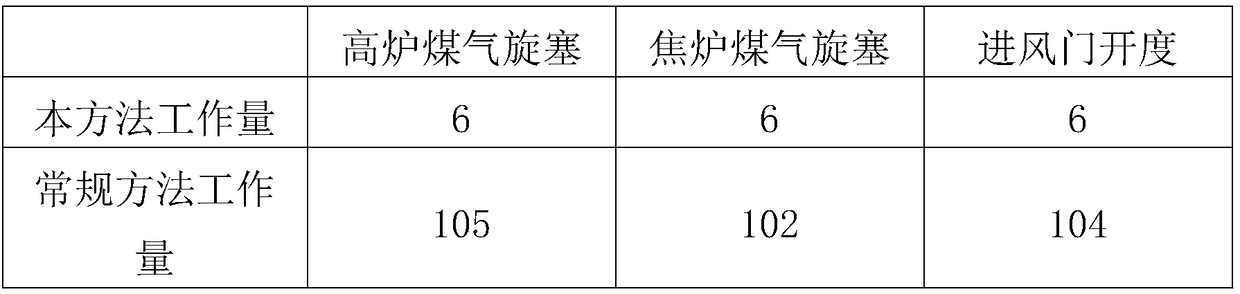

Image

Examples

Embodiment

[0025] Embodiment: In the method for replacing the coal gas heating of the partial combustion chamber of the coke oven, in the case of blast furnace gas heating, the furnace wall of the 50# carbonization chamber is excavated and repaired. This method only needs to replace the 50# and 51# combustion chambers with coke oven gas for heating, and the specific process is as follows:

[0026] (1) Close the 50#, 51# and 52# machine side-coke side blast furnace gas addition and subtraction cocks, close the machine-coke side 50#, 51# supplementary heating of the burner and the 49# single-eye and 52# double-eye burner Supplementary heating;

[0027] (2) Open the coke oven gas addition and subtraction cocks corresponding to 49# single eye, 50# single double eye, 51# single double eye, and 52# double eye until the opening is 25%;

[0028] (3) Remove the original large air door cover plate with a width of 100mm and a small iron plate for 50#, 51#, 52# of the machine-coke side flue, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com