Preparation method and equipment of combustible refuse fuel rod

A technology for waste fuel and equipment, which is applied in the field of rapid reduction of combustible garbage to prepare high-density fuel rods, can solve the problems of loose volume of combustible garbage, low calorific value per unit volume, and difficulty in storage and transportation. Low, meet the effect of combustion demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

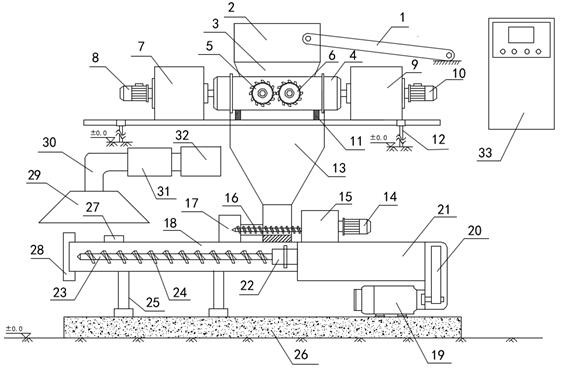

[0037] An equipment for preparing combustible garbage fuel rods, including a feeding device, a crushing device, an extrusion device, an exhaust gas purification system and an electrical control system; wherein

[0038] The feeding device is a lifting belt conveyor 1, and one side of the lifting belt conveyor 1 is arranged above the raw material hopper 3 in the dust-proof box 2;

[0039] The crushing device is a double-toothed roller crusher, which mainly includes: a crushing motor, a reduction box, a gear box, a dust-proof box, a raw material bucket, a base, and a frame; the gear box 4 is provided with a first crushing roller that rotates in opposite directions The wheel 5 and the second crushing roller 6 are respectively connected with the first reduction box 7, the first crushing motor 8, the second reduction box 9 and the second crushing motor 10 on both sides of the gear box in turn; the upper part of the gear box is provided with raw materials Bucket 3, a dustproof box 2 ...

Embodiment 2

[0043] A preparation method of combustible garbage fuel rod:

[0044] (1) After the combustible garbage is dried or aired to a moisture content of 10%, it is transported to the raw material hopper of the double-toothed roller crusher by the lifting belt conveyor. dust pollution;

[0045] (2) The two round rollers in the double-toothed roller crusher rotate in opposite directions, and the combustible garbage is rolled into the crushing cavity formed by the two rollers and crushed into fragments with a particle size of 4cm; under the action of gravity, the crushed garbage is Discharge from the gap between the two rollers into the extruder feed hopper;

[0046] (3) The garbage in the feeding hopper enters the feeding cavity under the transmission of the spiral blade on the feeding screw, and then falls from the feeding cavity to the feeding end of the extrusion barrel to realize the transmission of garbage in batches and reduce extrusion. Accumulation and blockage of materials ...

Embodiment 3

[0051] Actual usage description:

[0052] The combustible garbage after garbage classification in a district of Tianjin is mainly composed of plastic bags, plastic bottles, plastic ropes, old fabrics, cartons, waste rubber, etc. After drying to a moisture content of 15%, the method and device of the present invention are used to process the fuel rod. The combustible garbage is transported to the raw material hopper of the double-toothed roller crusher by the lifting belt conveyor, and crushed into pieces with a particle size of 3cm. Then it enters the feed hopper of the single screw extruder, the screw speed of the extruder is set to 30 rpm, the temperature of the waste debris is controlled to rise to 120 ° C, the diameter of the discharge port on the cutting die is 3.5 cm, and the cutting knife is cut into pieces. A fuel rod with a diameter of 3.5cm and a length of 10cm.

[0053] Referring to GB / T30727-2014 "Method for Determination of Calorific Value of Solid Biomass Fuel"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com