High-temperature smelting furnace and metallurgy method using same

A smelting furnace and high-temperature technology, applied in the field of metallurgy, can solve problems such as lack of impurity removal and alloying of molten iron, low purity of metal melt, and inability to homogenize the melt, so as to shorten the discharging time, improve the smelting effect, Realize the effect of molten iron alloying and impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides a high-temperature smelting furnace.

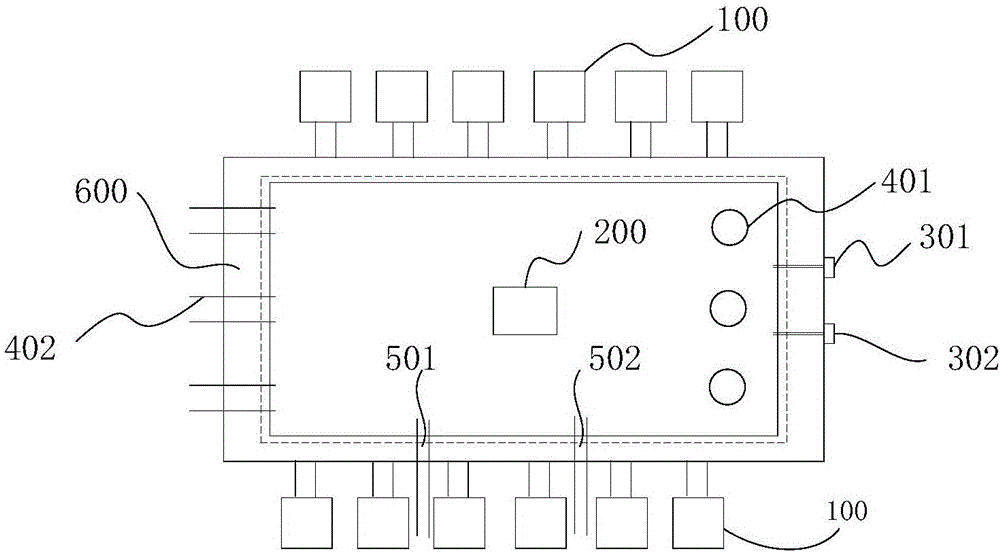

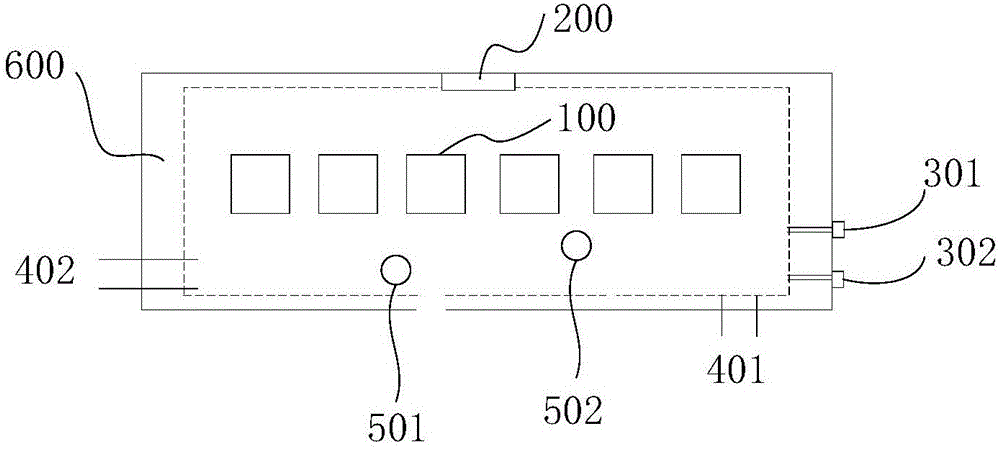

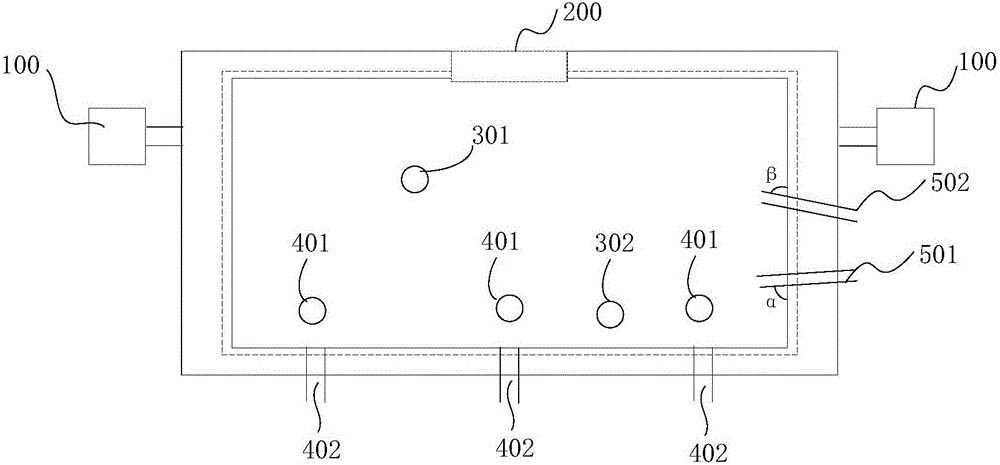

[0073] see figure 1 , figure 2 and image 3 The high-temperature smelting furnace provided in this embodiment includes a burner 100, a feeding port 200, a slag outlet 301, a steel tapping port 302, a furnace bottom injection device 401, a furnace wall side wall injection device 402, and an alloy feeding device 501, The refining slag feeding device 502 and the furnace body 600 of the smelting furnace.

[0074] The high-temperature smelting furnace has four side furnace walls, which are respectively the first side furnace wall and the second side furnace wall arranged oppositely in the length direction, the third side furnace wall and the fourth side furnace wall arranged oppositely in the width direction, and also includes Stove top and bottom.

[0075] In this embodiment, the burners 100 are arranged on the first side furnace wall and the second side furnace wall. Depend on figure 1 and figure 2 It...

Embodiment 2

[0081] like Figure 4 As shown, this embodiment provides a metallurgical method using the high-temperature smelting furnace provided in Embodiment 1. The method is as follows:

[0082] The metallized pellet material is fed from the charging port 200 on the top of the smelting furnace, and the gas and auxiliary gas enter together from the burner 100, and heat is released after combustion to reach the temperature required for melting the metallized pellets. With the continuous addition and melting of metallized pellets, a melt with a certain depth of molten pool is gradually formed in the smelting furnace body 600 . Then, the furnace bottom injection device 401 and the furnace wall side wall injection device 402 are turned on, and the high-velocity gas loaded with reducing agent is injected into the furnace pool. The gas used is the high-temperature flue gas discharged from the high-temperature smelting furnace, and the reducing agent used is semi-coke powder. The amount of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com