800MPa-grade steel for ships and preparation method of 800MPa-grade steel

A technology for marine use and impurities, which is applied in the field of marine steel and its preparation, and achieves the effects of good low temperature toughness, fine structure and grain, and excellent crack arrest performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

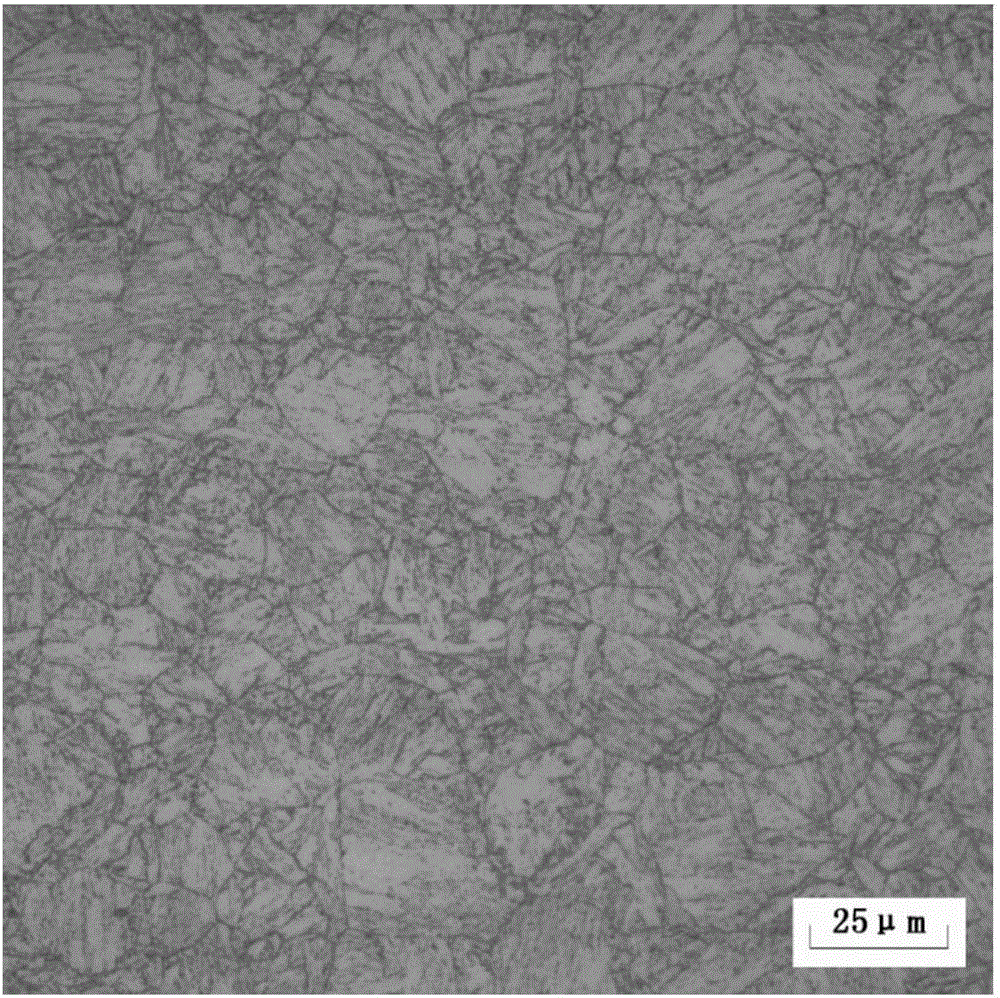

Image

Examples

Embodiment 1

[0018] The weight percentage of the chemical composition of the billet includes, C: 0.081%, Si: 0.22%, Mn: 0.84%, P: 0.007%, S: 0.0041%, B: 0.001%, Ni: 4.78%, Cr: 0.74%, Mo: 0.62%, V: 0.050%, the rest is Fe and unavoidable impurities.

[0019] 1. Smelting and forging: Use a 500Kg vacuum smelting furnace to make steel, and forge it into a 175mm billet after casting;

[0020] 2. Heating system: heating to 1200°C, holding for 3 hours;

[0021] 3. Rolling process: The rolling process is divided into two stages, rolling in the recrystallization zone and rolling in the non-recrystallization zone: the rolling start temperature in the recrystallization zone stage is 1087 ° C, and a total of 4 passes are rolled to the intermediate billet The thickness to be warmed is 60mm; the rolling to the non-recrystallized area is carried out when the temperature is reached to 870°C, the final rolling temperature is 817°C, and a total of 5 passes are rolled to the target thickness of 20mm;

[002...

Embodiment 2

[0026] The chemical composition of the billet includes by weight percentage, C: 0.078%, Si: 0.21%, Mn: 0.69%, P: 0.007%, S: 0.0041%, B: 0.0006%, Ni: 4.5%, Cr: 0.667%, Mo: 0.527%, V: 0.043%, and the rest are Fe and unavoidable impurities.

[0027] Smelting and forging, heating system are the same as embodiment 1.

[0028] Rolling process: The rolling process is divided into two stages, rolling in the recrystallization zone and rolling in the non-recrystallization zone: the rolling start temperature in the recrystallization zone stage is 1057 ° C, and a total of 4 passes are rolled until the intermediate billet is warmed The thickness is 60mm; when the temperature reaches 860°C, it is rolled in the non-recrystallized zone, the final rolling temperature is 810°C, and rolled for 5 passes to the target thickness of 20mm;

[0029] Cooling process after rolling: water cooling to 450°C after rolling, cooling rate 12°C / s, then air cooling to room temperature;

[0030] Heat treatment ...

Embodiment 3

[0033] The chemical composition of the billet includes by weight percentage, C: 0.076%, Si: 0.20%, Mn: 0.83%, P: 0.007%, S: 0.0044%, B: 0.0003%, Ni: 4.83%, Cr: 0.73%, Mo: 0.521%, V: 0.039%, and the rest are Fe and unavoidable impurities.

[0034] Smelting and forging, heating system are the same as embodiment 1;

[0035] Rolling process: The rolling process is divided into two stages, rolling in the recrystallization zone and rolling in the non-recrystallization zone: the rolling start temperature in the recrystallization zone stage is 1050 ° C, and a total of 3 passes are rolled until the intermediate billet is warmed The thickness is 85mm; when the temperature reaches 850°C, it is rolled in the non-recrystallized zone, and the final rolling temperature is 820°C, and it is rolled for 3 passes to the target thickness of 40mm;

[0036] Cooling process after rolling: air cooling to room temperature after rolling;

[0037] Heat treatment process: water quenching after quenching a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Lateral impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com