A tiltable rotary table

A technology of rotating worktable and rotating teeth, applied in the field of tiltable rotating worktable, can solve problems such as harsh working environment, and achieve the effect of reducing labor intensity, ensuring cleaning quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

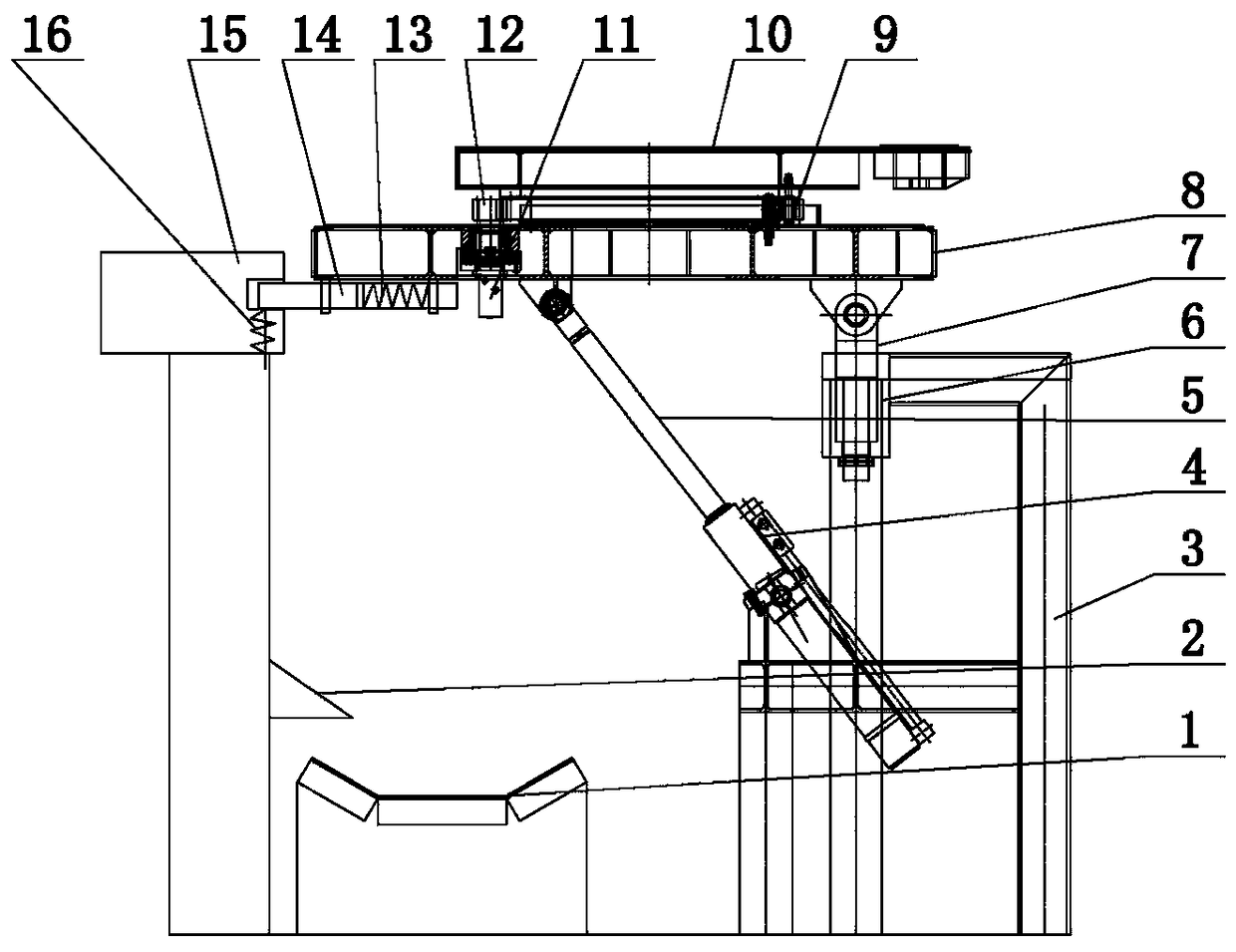

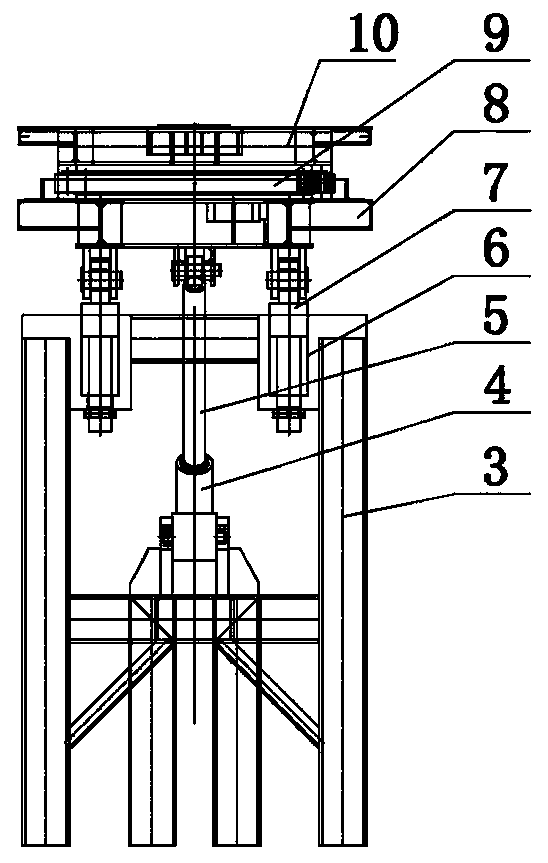

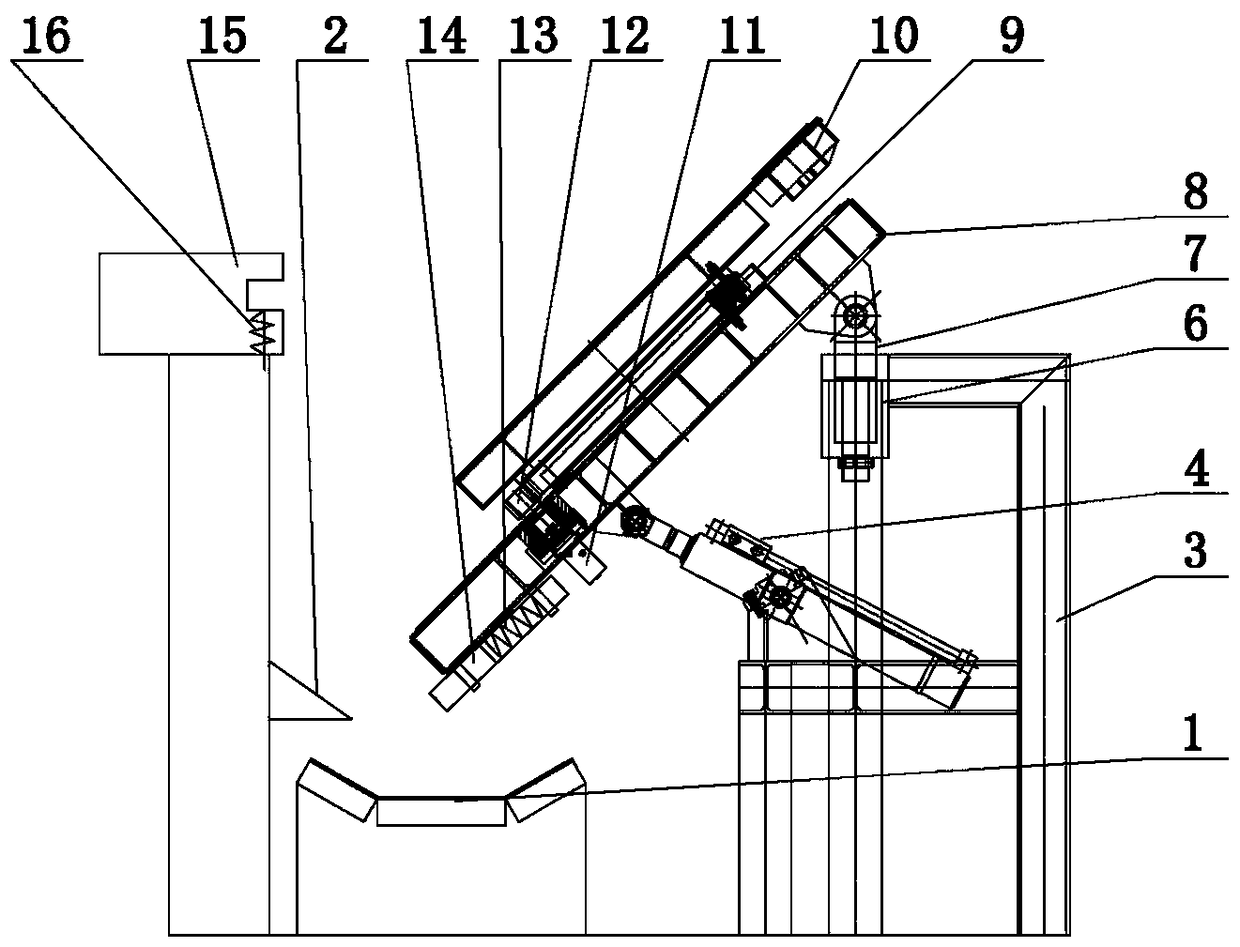

[0020] The present invention includes a fixed frame 3 and a rotary bracket 8, and is characterized in that: one end of the rotary bracket 8 is hinged with the fixed frame 3, and a rotary table 10 is arranged on the rotary bracket 8 through a rotating ring gear 9; a hydraulic motor is arranged on the rotary bracket 8 11. The driving gear 12 on the hydraulic motor 11 meshes with the rotating ring gear 9; the other end of the slewing bracket 8 is provided with a horizontal latch 14 through a return spring 13; corresponding to the horizontal latch 14, a self-locking groove body 15 is provided ; The fixed frame 3 is hingedly provided with a drive cylinder 4 , and the piston rod 5 of the drive cylinder 4 is hinged with the bottom of the rotary bracket 8 .

[0021] As a preferred solution of the present invention, the slewing bracket 8 is hinged with the guide support 7 on the fixed frame 3; a first buffer spring 6 is arranged between the guide support 7 and the fixed frame 3; the sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com