Bamboo-based label paper for cigarettes and preparation method thereof

A trademark paper, bamboo-based technology, applied in the direction of using inorganic alkali pulping, papermaking, packaging paper, etc., can solve the problems of unenvironmental protection, pollution, waste of resources, etc., and achieve the effect of fine fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

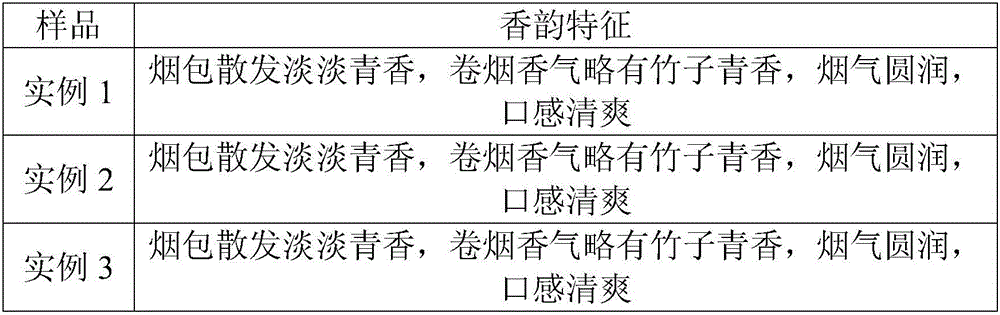

Examples

Embodiment 1

[0026] A preparation method for bamboo-based cigarette label paper, comprising the following steps:

[0027] 1) Air-dry the Nenci bamboo, retting it in the cellar for 40 days, take it out and dry it, cut it, smash it, stack it neatly in the retting pool, soak it with lime for 15 days, and then cook it for 7 days;

[0028] 2) Roughly beating and finely beating the cooked bamboo material until the fibers are split, washed with clear water and re-cooked for 5 days to decompose the bamboo fiber and soften the mature material;

[0029] 3) Naturally ferment the clinker in rice soup for 7 days, mash it into velvet, and prepare a bamboo pulp slurry with a beating degree of 22°SR;

[0030] 4) Copy the bamboo pulp slurry into 200g / m 2 Bamboo base paper;

[0031] 5) coating weight ratio on the bamboo base base paper is 5% bamboo extract, and its proportioning is: 18% of bamboo juice, 10% of bamboo leek, 5% of Cizhu flower extract, 3% of bamboo leaf essential oil, and the balance is 10...

Embodiment 2

[0034] 1) Air-dry the Nenci bamboo, retting it in the cellar for 40 days, take it out and dry it, cut it, smash it, stack it neatly in the retting pool, soak it with lime for 15 days, and then cook it for 7 days;

[0035] 2) Roughly beating and finely beating the cooked bamboo material until the fibers are split, washed with clear water and re-cooked for 5 days to decompose the bamboo fiber and soften the mature material;

[0036] 3) Naturally ferment the clinker in rice soup for 7 days, mash it into velvet, and prepare a bamboo pulp slurry with a beating degree of 35°SR;

[0037] 4) Copy the bamboo pulp slurry into 220g / m 2 Bamboo base paper;

[0038] 5) coating weight ratio on the bamboo base base paper is 15% bamboo extract, and its proportioning is: 18% of bamboo juice, 15% of bamboo leek, 8% of Cizhu flower extract, 1% of bamboo leaf essential oil, and the balance is 10% aqueous solution of propylene glycol.

[0039] 6) Drying at low temperature, cutting and packaging,...

Embodiment 3

[0041] 1) Air-dry the Nenci bamboo, retting it in the cellar for 40 days, take it out and dry it, cut it, smash it, stack it neatly in the retting pool, soak it with lime for 15 days, and then cook it for 7 days;

[0042] 2) Roughly beating and finely beating the cooked bamboo material until the fibers are split, washed with clear water and re-cooked for 5 days to decompose the bamboo fiber and soften the mature material;

[0043] 3) Naturally ferment the clinker in rice soup for 7 days, mash it into velvet, and prepare a bamboo pulp slurry with a beating degree of 45°SR;

[0044] 4) Copy the bamboo pulp slurry into 250g / m 2 Bamboo base paper;

[0045] 5) coating weight ratio on the bamboo-based base paper is 30% bamboo extract, and its proportioning is: 30% of bamboo juice, 5% of bamboo leek, 10% of Cizhu flower extract, 5% of bamboo leaf essential oil, and the balance is 10% aqueous solution of propylene glycol.

[0046] 6) Drying at low temperature, cutting and packaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com