Anticorrosion flexible guardrail and making method thereof

A technology of flexible guardrails and manufacturing methods, applied to roads, road safety devices, roads, etc., can solve the problems of short service life, low safety, and easy fading of guardrails, and achieve avoidance of secondary damage, good safety performance, and weather resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0043] Embodiment 1-5: the making of guardrail board

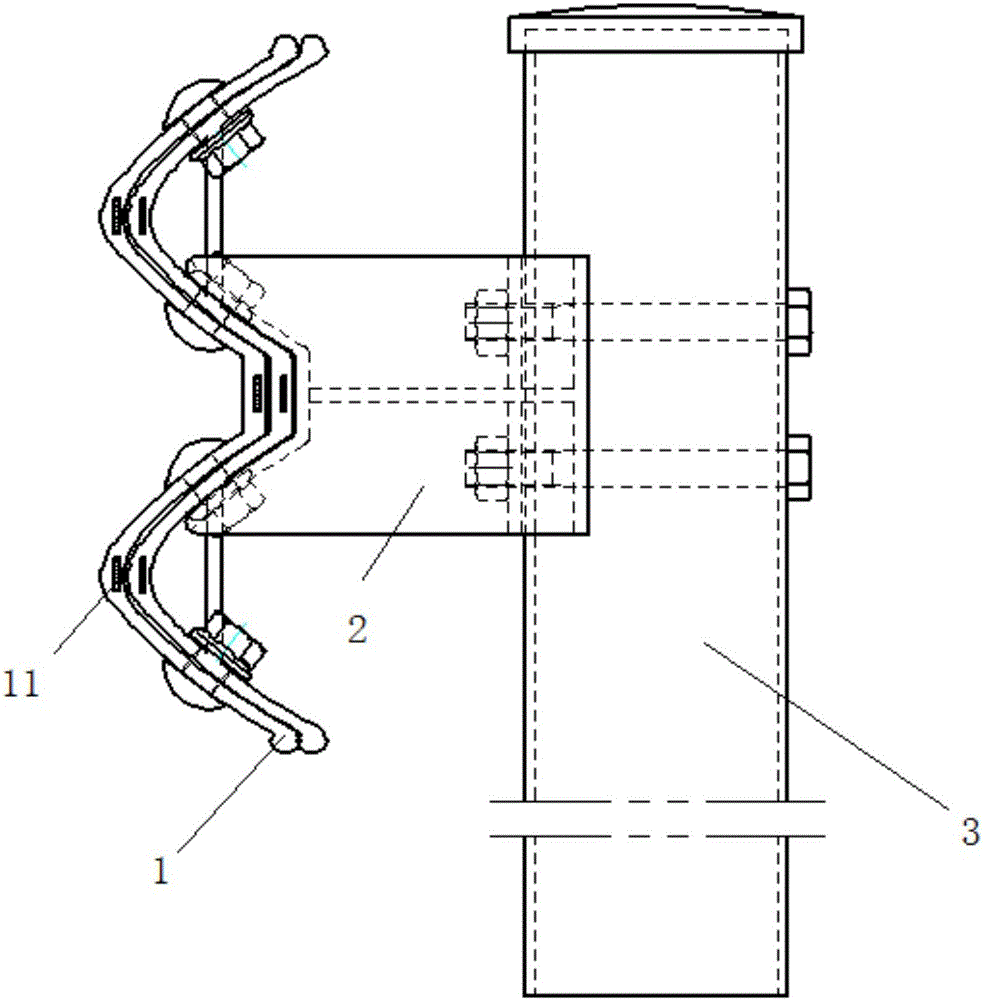

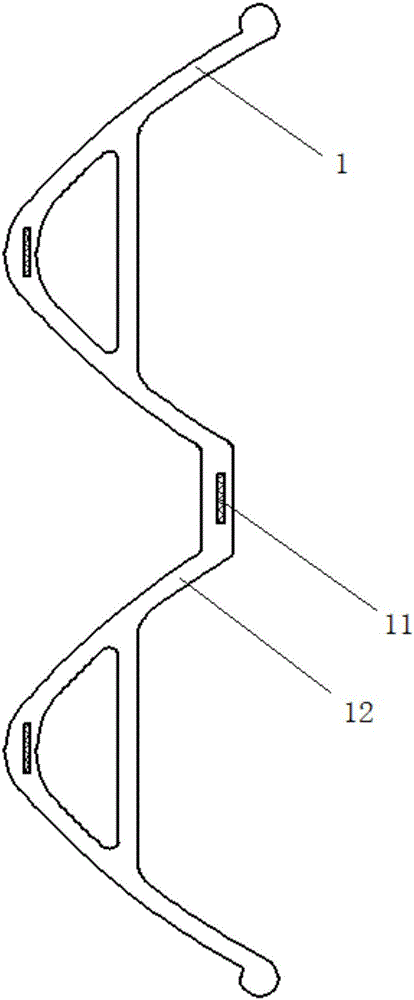

[0044] Such as figure 1 As shown, the length of the guardrail is 4320mm, the width of the guardrail is 310mm, the wave height is 85mm, and the wall thickness of the guardrail is 6-9mm.

[0045] Table 1:

[0046]

[0047] The production steps are as follows:

[0048] a. Fully mix the additives in the above Table 1 according to the above mass parts, and then add them together with ultra-high molecular weight polyethylene into a twin-screw extruder to extrude and pelletize. The extrusion temperature is 130-230 ° C, and the extrusion speed is 5 -15Hz, extrusion pressure 25-45Mpa;

[0049] b. Fix the aramid tape with a winding machine, transport the particles prepared in step a to the feed port of the co-extrusion screw extruder, and at the same time transport the fixed three aramid tapes or steel wire mesh to the co-extrusion screw extruder The mold distributor of the machine is locked, the extrusion temperature is 130-...

Embodiment 6-10

[0053] Embodiment 6-10: Add the making of a longitudinal rib guardrail board on the waist of W shape:

[0054] Such as figure 2 As shown, the geometric shape design of the anti-corrosion flexible guardrail is 4320mm in length, 310mm in width, 85mm in wave height, and 6-9mm in wall thickness.

[0055] table 3

[0056]

UPE

flame retardant

anti aging agent

Anti-ultraviolet agent

Example 6

100

8

1

1.1

0.8

0.3

10

2

Example 7

100

11

1.5

1

1.1

0.3

10

3

Example 8

100

12

1.1

1.2

1.2

0.3

10

1

Example 9

100

9

1.3

1

1.3

0.3

10

3

Example 10

100

10

1.2

1.1

1.4

0.3

10

1

[0057] The production steps are as follows:

[0058] a. Fully mix the additives in the above Table 3 according to the above mass parts, and then add them to the tw...

Embodiment 11-15

[0063] Example 11-15: Fabrication of anti-blocking blocks

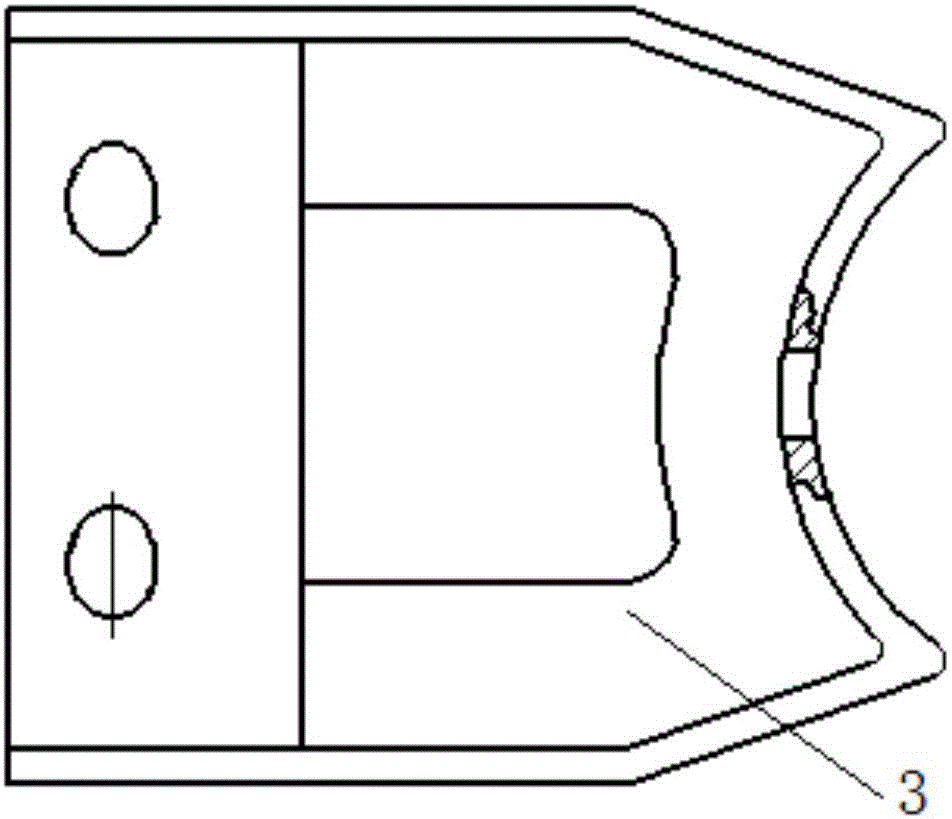

[0064] Such as image 3 As shown, the geometric shape of the guardrail (W type) anti-blocking block is frame type, the design length is 170mm, the two ends are clamp-shaped, the width is rectangular 120mm*140mm, and the thickness of the board wall is 12mm.

[0065] The raw material of embodiment 11-13 and the mass parts that add thereof are:

[0066] table 5

[0067]

[0068] The production steps are as follows: mix the mass parts in Table 5 of the above-mentioned raw materials evenly, and then inject them into an injection molding machine for injection molding. The injection molding temperature is , and the injection molding pressure is .

[0069] The anti-blocking block that above embodiment is made carries out performance test, and result is as follows:

[0070] a. Tensile strength: 280-300Mpa

[0071] b. Elongation at break 80%

[0072] c. Impact strength: 180Kj / m2

[0074...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com