Sludge solidification treatment equipment and method

A technology of solidification treatment and silt, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of damage to the ecological environment, low bearing capacity of the foundation, poor durability, etc., to avoid secondary pollution, reduce material costs, reduce The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

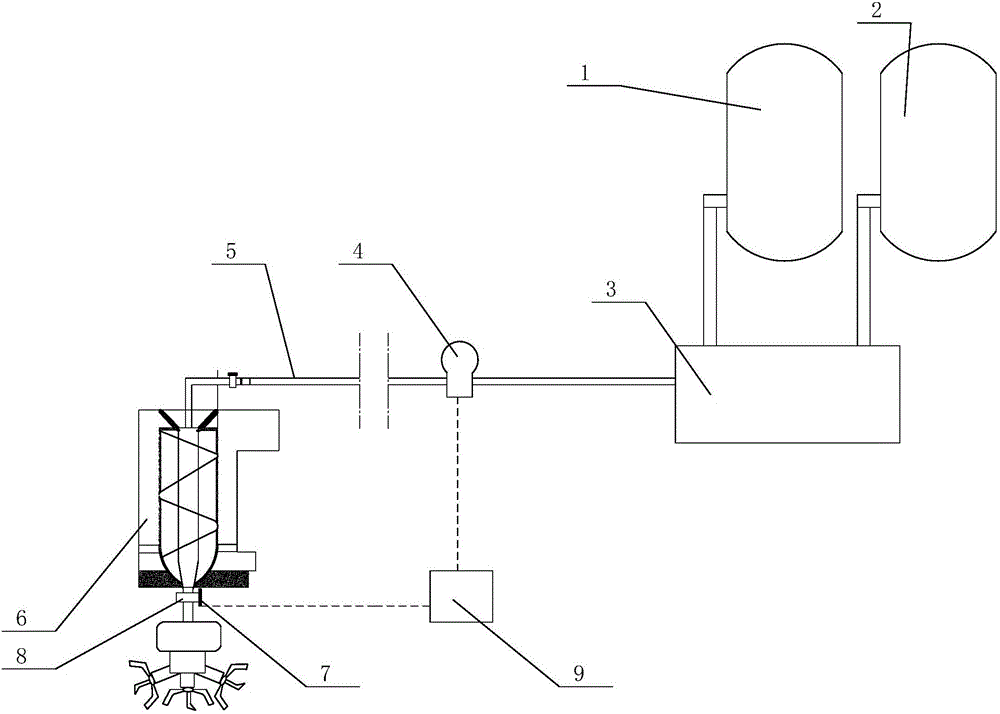

[0031] as attached figure 1 As shown, a kind of sludge solidification treatment equipment includes a curing agent storage tank 1 and a water tank 2, the curing agent storage tank 1 and the water tank 2 are jointly connected with a curing agent mixer 3, and the described curing agent mixer 3 is equipped with a The pipeline 5 of the pressure pump 4 is connected to the sludge solidification mixer 6, and the curing agent outlet 7 on the sludge solidification mixer 6 is provided with a pressure sensor 8, and the pressure sensor 8 is electrically connected to the booster pump controller 9, The booster pump controller 9 is electrically connected to the booster pump 4 .

[0032] The sludge solidification mixer in this embodiment includes a casing, and a rotating drum is arranged in the casing, and a spiral stirring mechanism is arranged in the rotating drum, and a curing agent feeding port is connected to the upper part of the rotating drum through a pipeline, so that A curing agent ...

Embodiment 2

[0034] A method for solidifying sludge, comprising the steps of:

[0035] A. First mix the curing agent with an appropriate proportion of water to prepare a slurry;

[0036] B. Then transport the slurry to the sludge solidification mixer at the foundation construction position;

[0037] C. The silt solidification mixer injects the slurry directly into the soft soil with high water content, and at the same time uses the silt solidification mixer to directly stir on the spot until the slurry is evenly mixed with the entire soft soil base, and consolidated to form a consolidated body.

[0038] The silt solidification mixer adopts the construction method equipped with excavators. The construction area is on the side of the excavator, and the forward direction of the excavator is parallel to the construction area. Sand and gravel or mountain soil are spread in the newly constructed area as a surcharge layer and flattened. After rolling, it will be used as the next construction pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com