Radiating fin

A technology of heat sink and single heat sink, which can be used in household heating, heating methods, electric heating systems, etc., can solve the problems of slow air convection, waste of resources, and high cost, and achieve improved mechanical strength, strong air convection, and production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

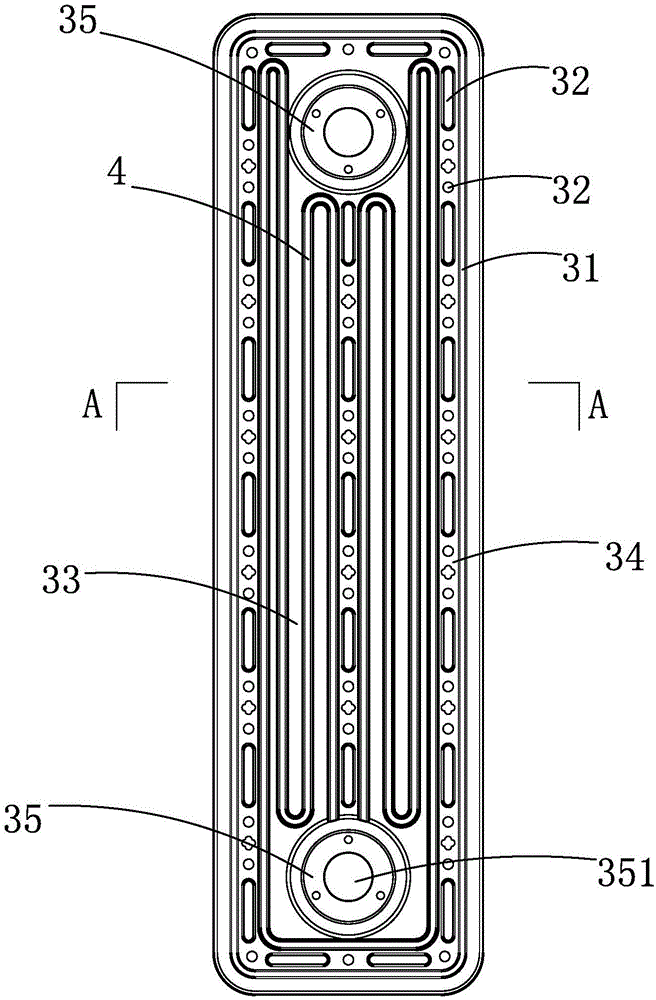

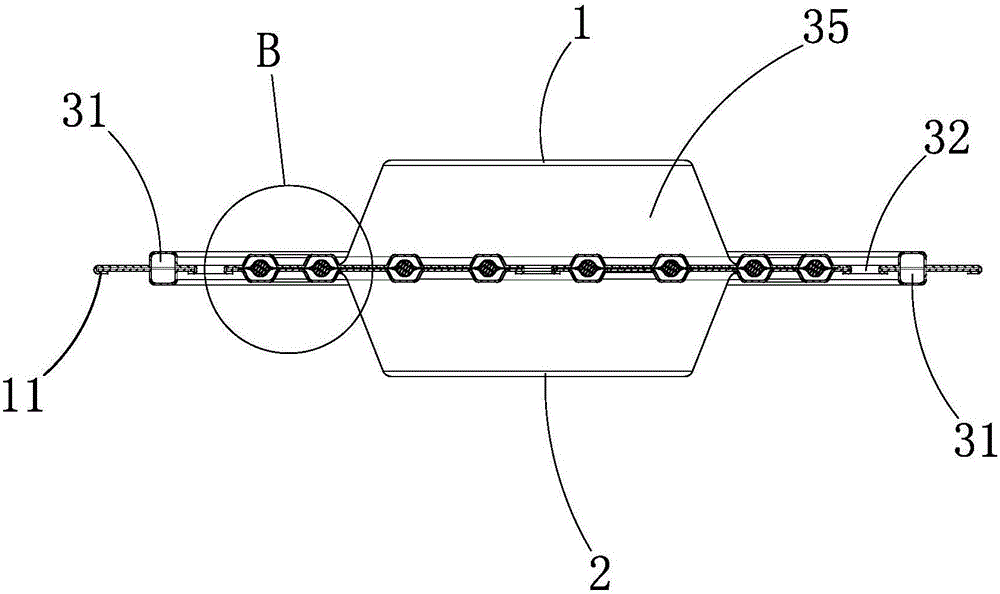

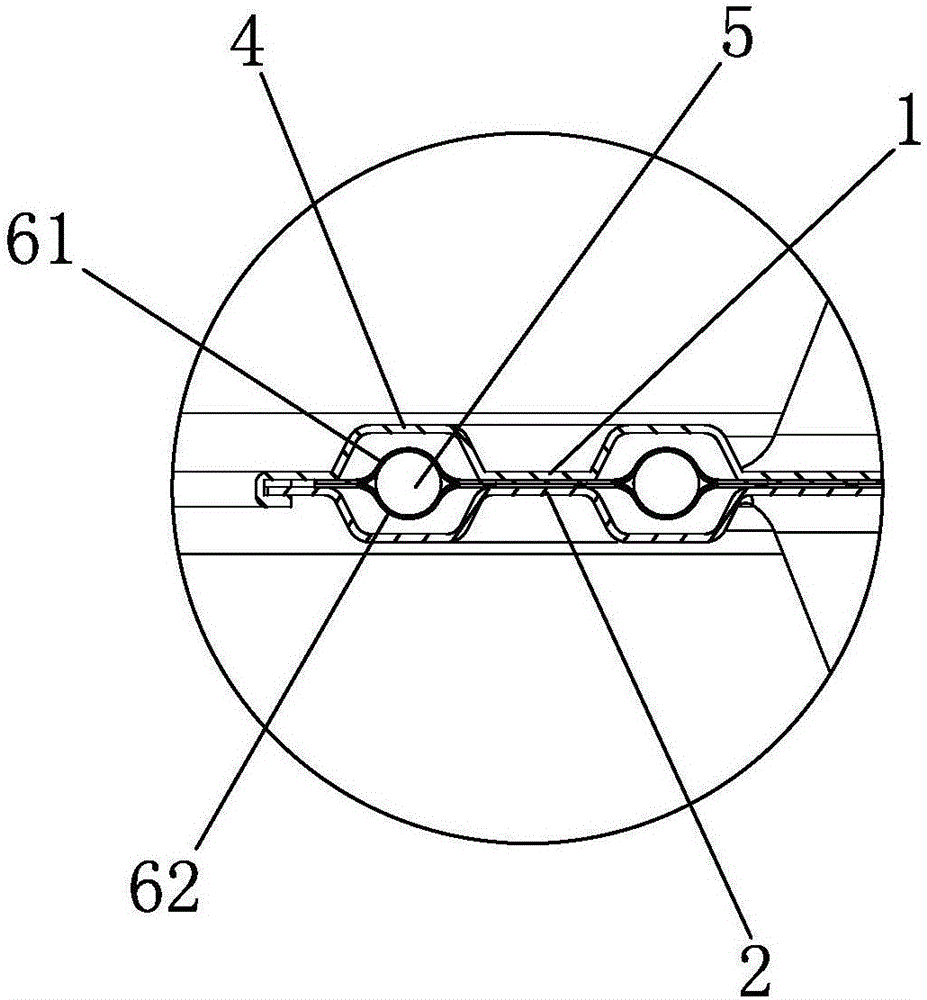

[0053] see Figure 1 to Figure 5 According to the heat sink embodiment provided by the present invention, it includes a first heat dissipation sheet 1 and a second heat dissipation sheet 2 that are buckled and connected together, and the first heat dissipation sheet 1 and the second heat dissipation sheet 2 There is an insulated electric heating cord 5 between them, and a cord channel 4 that matches the track of the insulated electric heating cord 5 is arranged between the first heat dissipation single piece 1 and the second heat dissipation single piece 2. The insulated electric heating flexible wire 5 is located in the flexible wire channel 4, and there are heat insulating ribs 31 and heat insulating holes 32 near the edge of the heat sink. 41%-91% of the length of the above-mentioned layout track. 75% is preferred in this embodiment. The first heat dissipation sheet 1 and the second heat dissipation sheet 2 can be interchanged. The present invention has the advantages of...

Embodiment 2

[0072] The structure of this embodiment is substantially the same as that of the first embodiment above, except that the structure of the positioning piece is different, that is, only one positioning piece is included. The positioning piece includes a third positioning piece, the insulated electric heating cord is located between the third positioning piece and the first heat sink, and the third positioning piece is clamped between the first heat dissipation single piece and the first heat dissipation sheet. between the second heat dissipation sheets. The third positioning piece is a tinfoil piece. The above-mentioned positioning piece has simple structure, convenient assembly, and low production cost. At the same time, tin foil is used as the third positioning piece, which has good thermal conductivity and has little influence on the thermal efficiency of the insulated electric heating cord.

Embodiment 3

[0074] The structure of this embodiment is substantially the same as that of the first embodiment above, except that the structure of the insulated electric heating cord is different. The insulated electric heating cord includes a wire tube and a resistance wire arranged in the wire tube. The cross-sectional area of the wire is larger than the cross-sectional area of the resistance wire in the second wire segment. The first wire segment and the second wire segment are integrally structured. The insulated electric heating flexible wire of this structure has the advantages of simple structure, few parts, convenient assembly, low production cost, high heating efficiency and high wiring efficiency; the wire tube is made of insulating material, and is safe and reliable during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com