Square vacuum drier

A vacuum dryer and dryer technology, used in drying chambers/containers, local stirring dryers, dryers for static materials, etc., can solve the problem that the production of qualified products cannot be guaranteed, the complete cleaning cannot be guaranteed, and there is no online cleaning system. and other problems, to achieve the effect of convenient disassembly and assembly, thorough cleaning, and accelerated drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

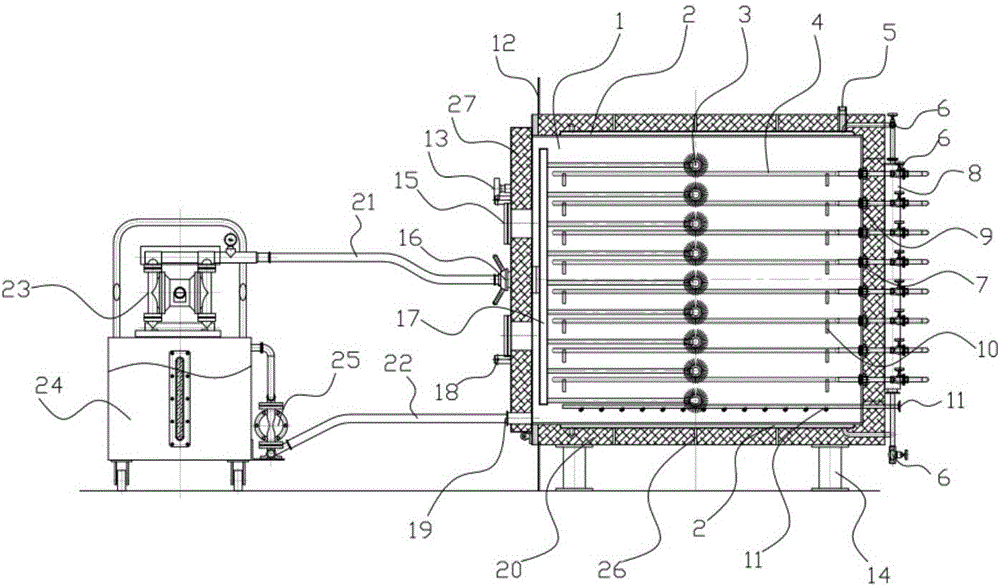

[0013] Such as figure 1 As shown, a high-efficiency square vacuum dryer 20 is a box-type mechanism with a vacuum door 20. The cavity is made of stainless steel plate, and the external profile is reinforced 26 to ensure that it will not be deformed under vacuuming. Heating layer 2, sealed with stainless steel, built-in stainless steel plate heater 4, fixed by external nut 7 of the water inlet and outlet pipes, rubber 9 packing seal is provided in the cavity, the temperature of the plate layer is adjusted and set by the regulating valve 6, and the plate layer drying rack 4 is placed On the shelf 10 welded on the cavity, there is a water bag 8 for total inlet and outlet, a nitrogen injection device 11 is provided at the bottom of the plate, the bottom plate is inclined to discharge sewage, and the sewage outlet 19 is on the door, which is convenient for cleaning. There are reinforcement ribs and heat preservation outer seal stainless steel, the door is provided with sight glass 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com