Operation method of three-dimensional substance surface scanning device based on intelligent sensing

A technology of intelligent sensing and three-dimensional scanning, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unsatisfactory measurement results, not fully applicable to log measurement, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

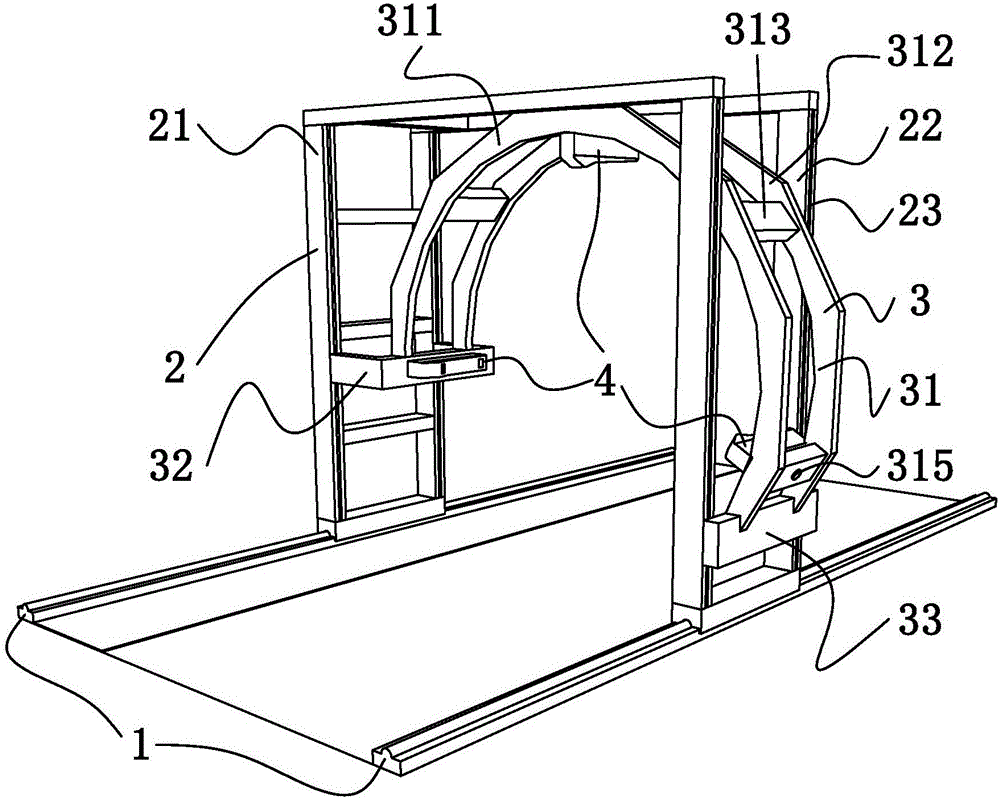

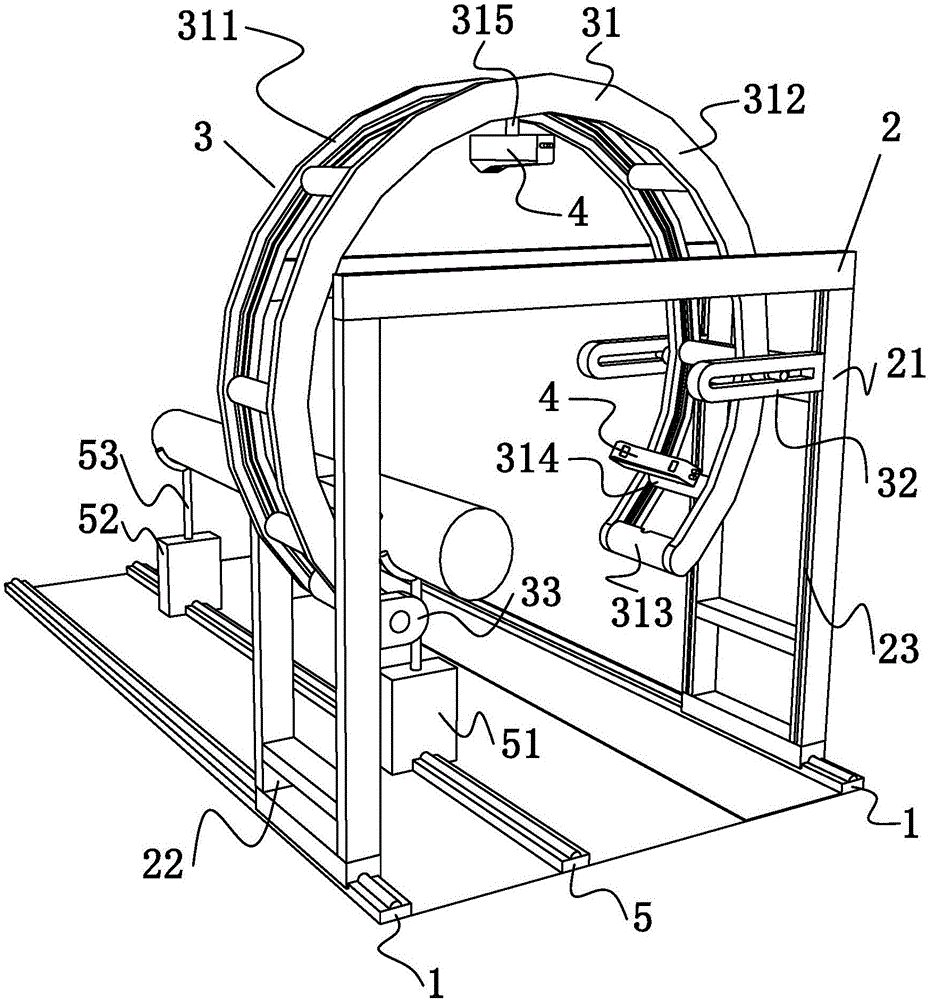

[0035] Specific Embodiment 1: Combining figure 1 with figure 2 Describe this embodiment, the material surface three-dimensional scanning device based on intelligent sensing described in this embodiment has a transmission slide rail 1 and a bracket 2 connected thereto, and the bracket 2 slides or is fixed on the transmission slide rail 1 , the support 2 has a first frame body 21 and a second frame body 22 arranged in parallel; the first frame body 21 and the second frame body 22 are provided with a transmission lifting rail 23 capable of lifting transmission; The transmission lifting rail 23 is connected with the lifting frame 3, and the laser scanning device 4 is installed on the lifting frame 3; The base 32 and the second lifting base 33, the first lifting base 32 is connected with the transmission lifting rail 23 on the first frame body 21, the second lifting base 33 is connected with the second frame body 22 is connected to the transmission lifting rail 23, one end of th...

specific Embodiment approach 2

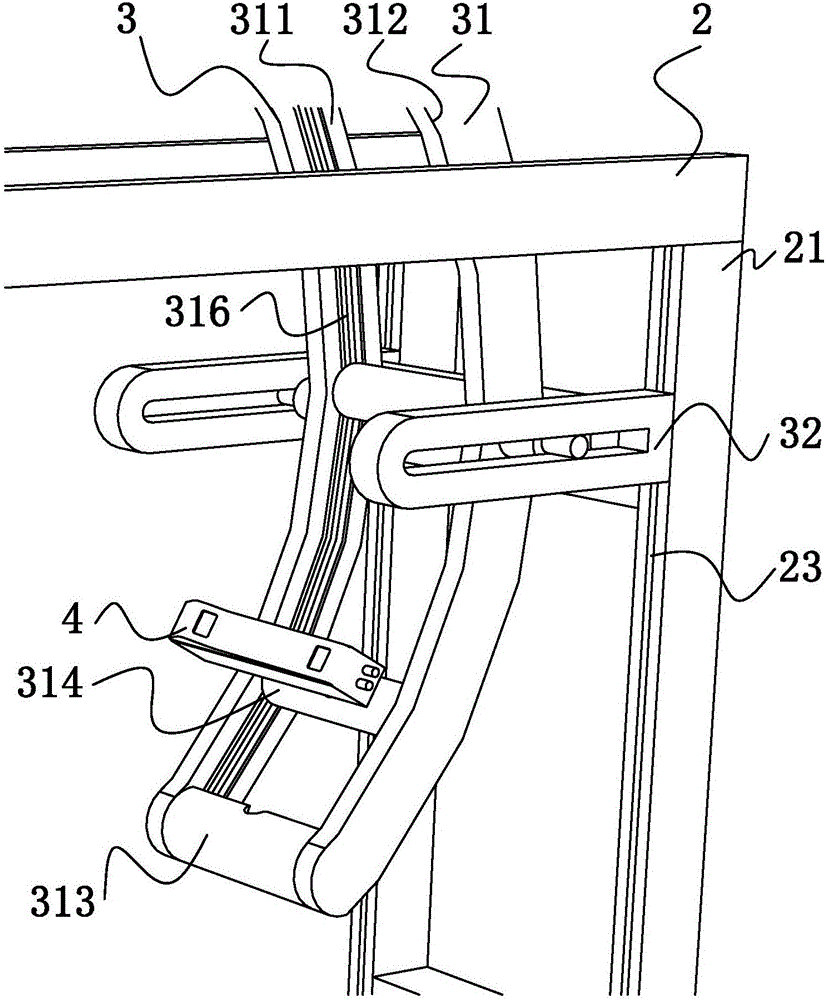

[0037] Specific Embodiment 2: Combining figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 Describe this embodiment, the material surface three-dimensional scanning device based on intelligent sensing in this embodiment, the two sides of the first lifting base 32 respectively have a first side arm 321 and a second side arm 322, the first Both the side arm 321 and the second side arm 322 have a side arm chute 323, and the arc-shaped frame body 31 has an arc drive rail 317, and the arc drive rail 317 has a slide shaft 318. The shaft 318 is slidably connected to the side arm sliding groove 323; the others are the same as in Embodiment 1.

[0038] The technical effect of this embodiment is: through the sliding connection between the sliding shaft and the side arm chute, the sliding connection between one end of the arc-shaped frame body and the first lifting base can be realized, so that the angle of the lifting frame It can be adjusted as needed to ensure that the th...

specific Embodiment approach 3

[0039] Embodiment 3: Combining figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 Describe this embodiment, the material surface three-dimensional scanning device based on intelligent sensing described in this embodiment, the two sides of the second lifting base 33 respectively have a first shaft protrusion 331 and a second shaft protrusion 332; The connection between the frame body 31 and the second lifting base 33 has a rotating shaft 333, and the hinged connection between the arc-shaped frame body 31 and the second lifting base 33 is realized through the rotating shaft 333; other and specific embodiments Any one of 1-2 is the same.

[0040] The technical effect of this embodiment is: the hinged connection between the arc-shaped frame body and the second lifting base can be realized through the rotating shaft, so that the lifting frame can rotate to a certain extent relative to the rotating shaft. The rotation can adjust the relative position betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com