Industrial system detection method with online detection and simulation modeling verification combined

A technology of simulation modeling and detection methods, applied in the field of track signals, can solve the problems of interfering with transportation production, potential safety hazards, testing methods, methods, cases, and limited test content, so as to achieve information sharing, overcome hardware redundancy, and improve The effect of measurement accuracy and anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

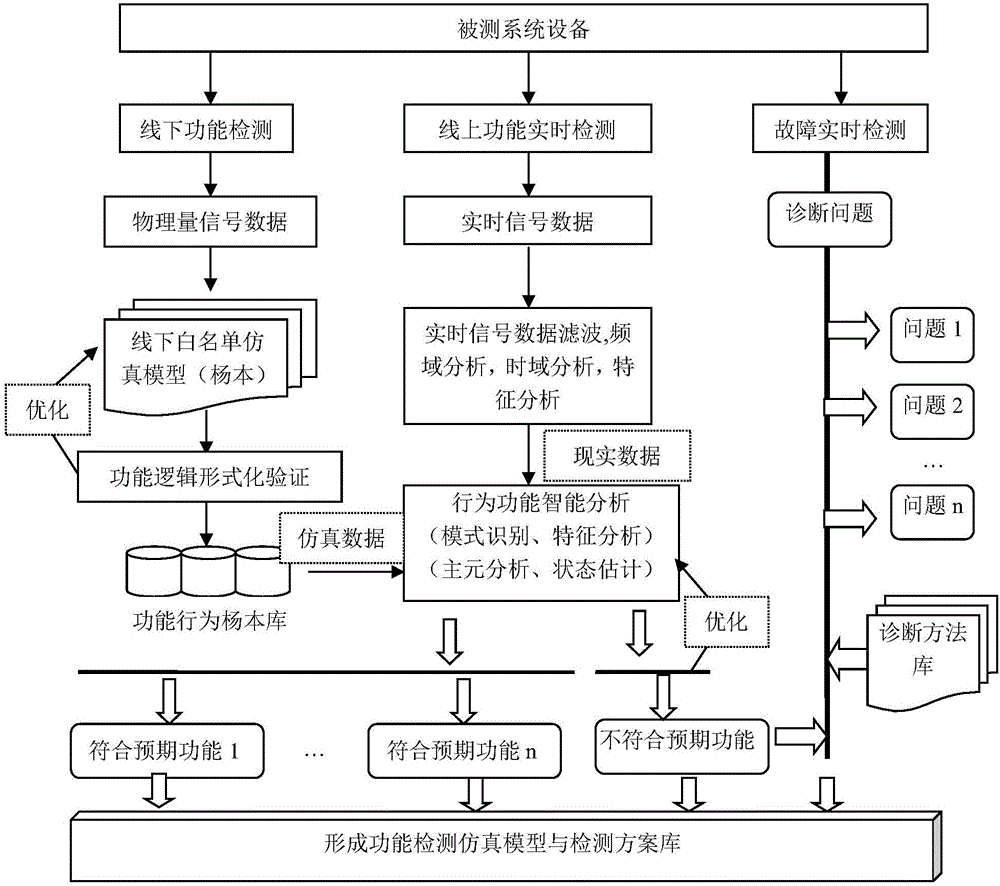

[0050] The industrial system detection method combining online detection and simulation modeling verification in this embodiment is to provide a reliability and safety test and evaluation method for rail signal system equipment, which is suitable for electrified and non-electrified sections and multiple sections in the rail transit field. General-purpose interval automatic blocking test evaluation of various track circuit types.

[0051] Such as figure 1 As shown, this method is oriented to industrial system equipment facing RAMS (reliability, availability, maintainability, and security) full life cycle process control problems. Based on the big data drive method and integrity soft measurement technology, the holographic data Digital modeling and operation safety evaluation platform, in order to improve the reliability, effectiveness, maintainability and safety of industrial control systems and products, and the automatic control field tends to "zero failure" requirements, imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com