Silicon-based microdisplay module group

A micro-display, silicon-based technology, applied to static indicators, instruments, etc., can solve the problems that silicon-based micro-display modules have not yet appeared, and achieve the effect of high display refresh rate, high display resolution, and improved transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

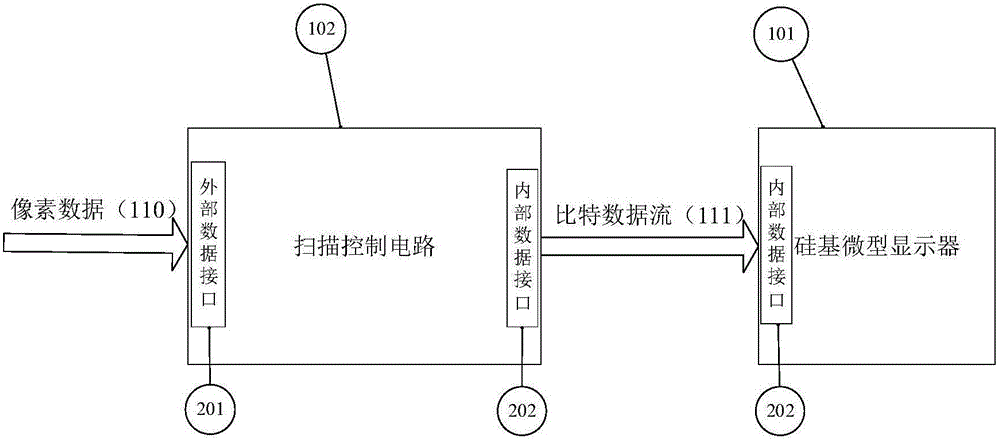

[0044] see figure 1 , the silicon-based micro-display module is characterized in that the silicon-based micro-display and the scanning control circuit are connected through a differential interface, and all light-emitting devices of the silicon-based micro-display are manufactured on the same single-crystal silicon chip through semiconductor technology, and all transistors formed by it are All work in digital switch mode, with only two states of "on" and "off", using digital pulse width modulation to control the brightness and grayscale of pixels. The scanning control circuit receives externally input pixel data and sends the bit plane data to the silicon-based microdisplay through a differential interface.

Embodiment 2

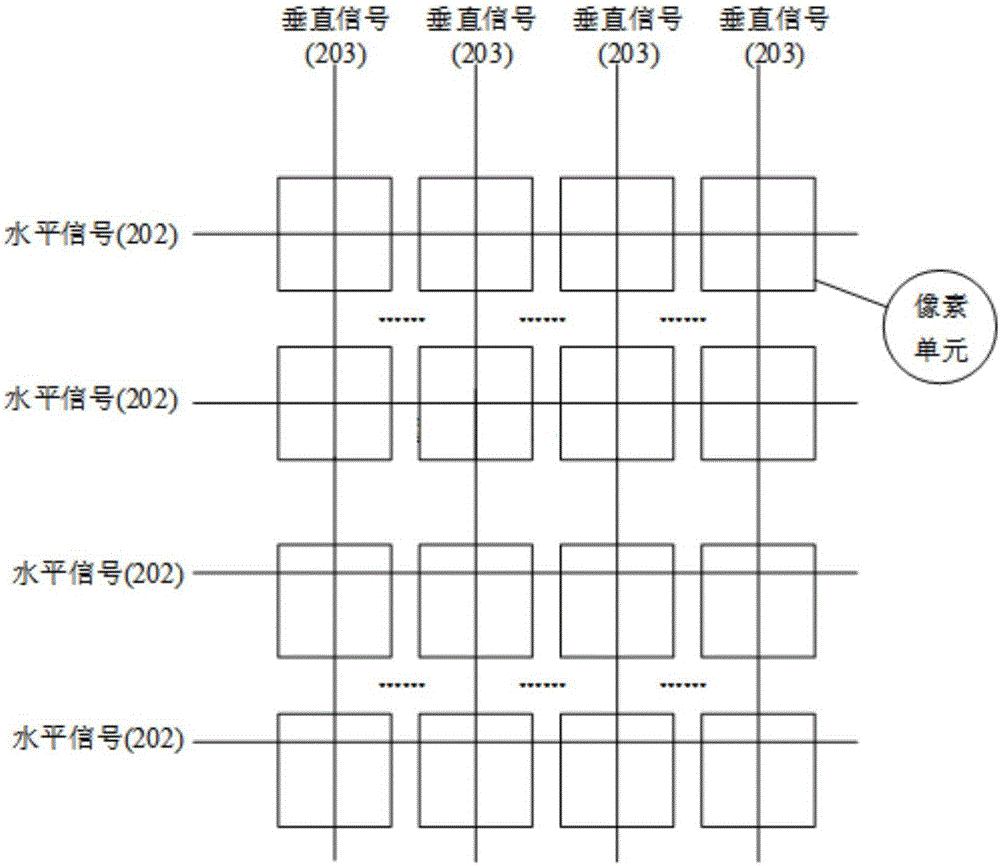

[0046] see figure 2 , The silicon-based microdisplay is characterized in that the visible area of the silicon-based microdisplay is any one of rectangle, square, rhombus, ellipse and perfect circle. The pixel array is arranged in matrix form, and the bright and dark states of the pixels are controlled by horizontal signals and vertical signals. A metal sheet is pasted under the silicon-based microdisplay for heat dissipation. The material of the metal sheet can be Al, Cu, Ag, Au, Pt, Cr, W, Mo, Ti, TiN, Sn, ITO, ZnO or these materials compound between.

Embodiment 3

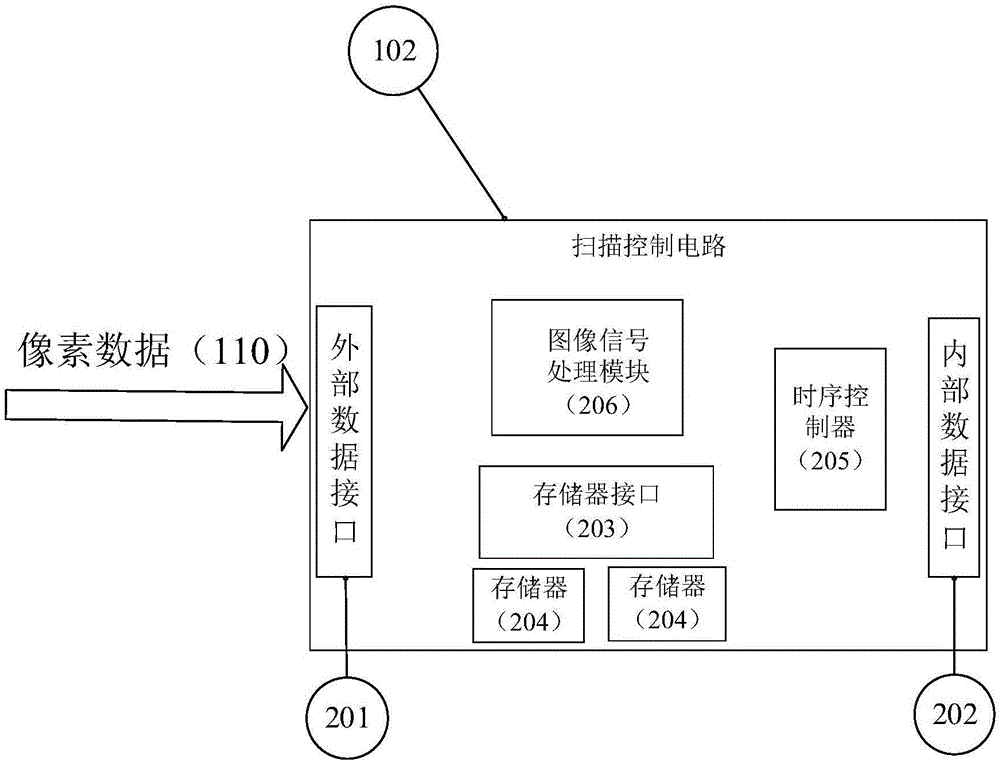

[0048] see image 3 , the scanning control circuit is characterized in that the scanning control circuit includes an external data interface, a memory interface, a memory, a timing controller, an image signal processing module, and an internal data interface for receiving pixel data, and the external data interface receives external external input Pixel data, its types include but not limited to VGA, A / V, DVI, HDMI, RGB, YCbCr, LVDS, MIPI, DisplayPort, eDP, PCI-Express, USB, IEEE1394. The memory is a dynamic memory or a static memory for storing pixel data. The timing controller is used to generate bit-plane timing signals to refresh silicon-based microdisplays. The image signal processing module reads the pixel data of the memory and performs image scaling, image rotation, gamma correction, YUV conversion to RGB, image enhancement, edge enhancement, grayscale nonlinear correction, image distortion correction and other processing. The internal data interface is a differentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com