A kind of production method of spiral armored cable

A technology for armored cables and production methods, which is applied in the direction of insulated cables, cable/conductor manufacturing, and cables. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to more fully understand the technical content of the present invention, the technical solutions of the present invention are further introduced and described below with reference to specific embodiments, but are not limited thereto.

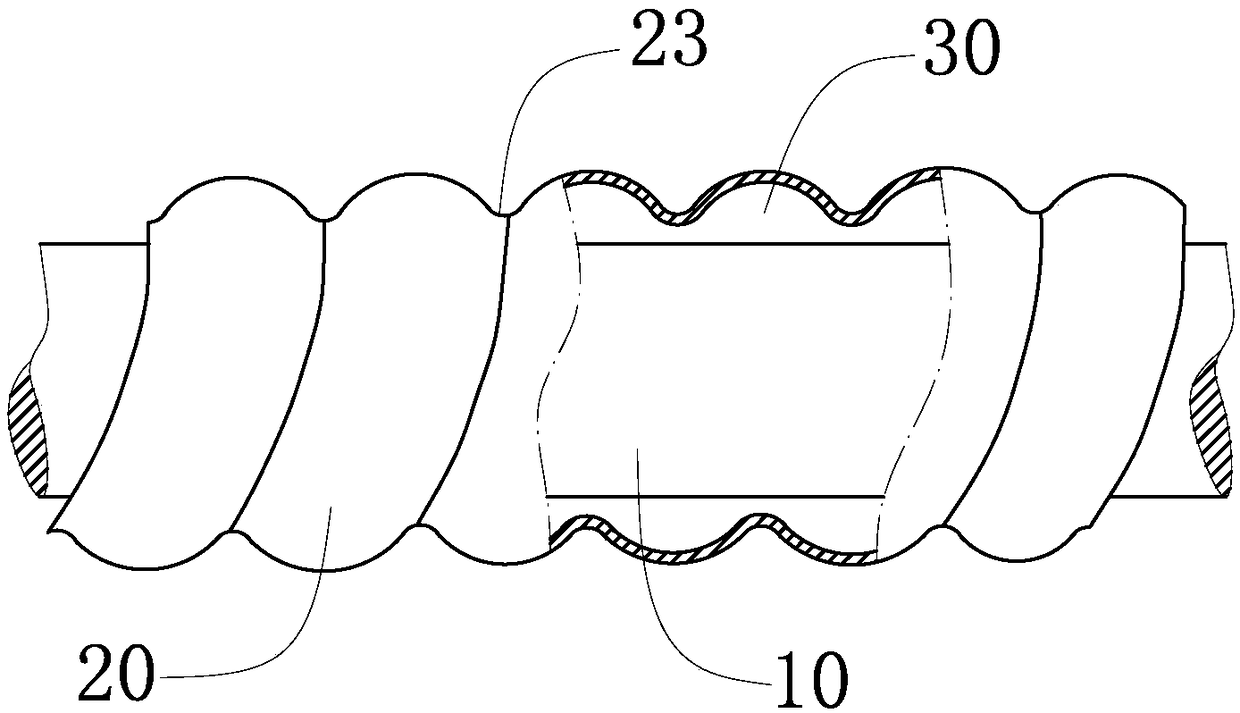

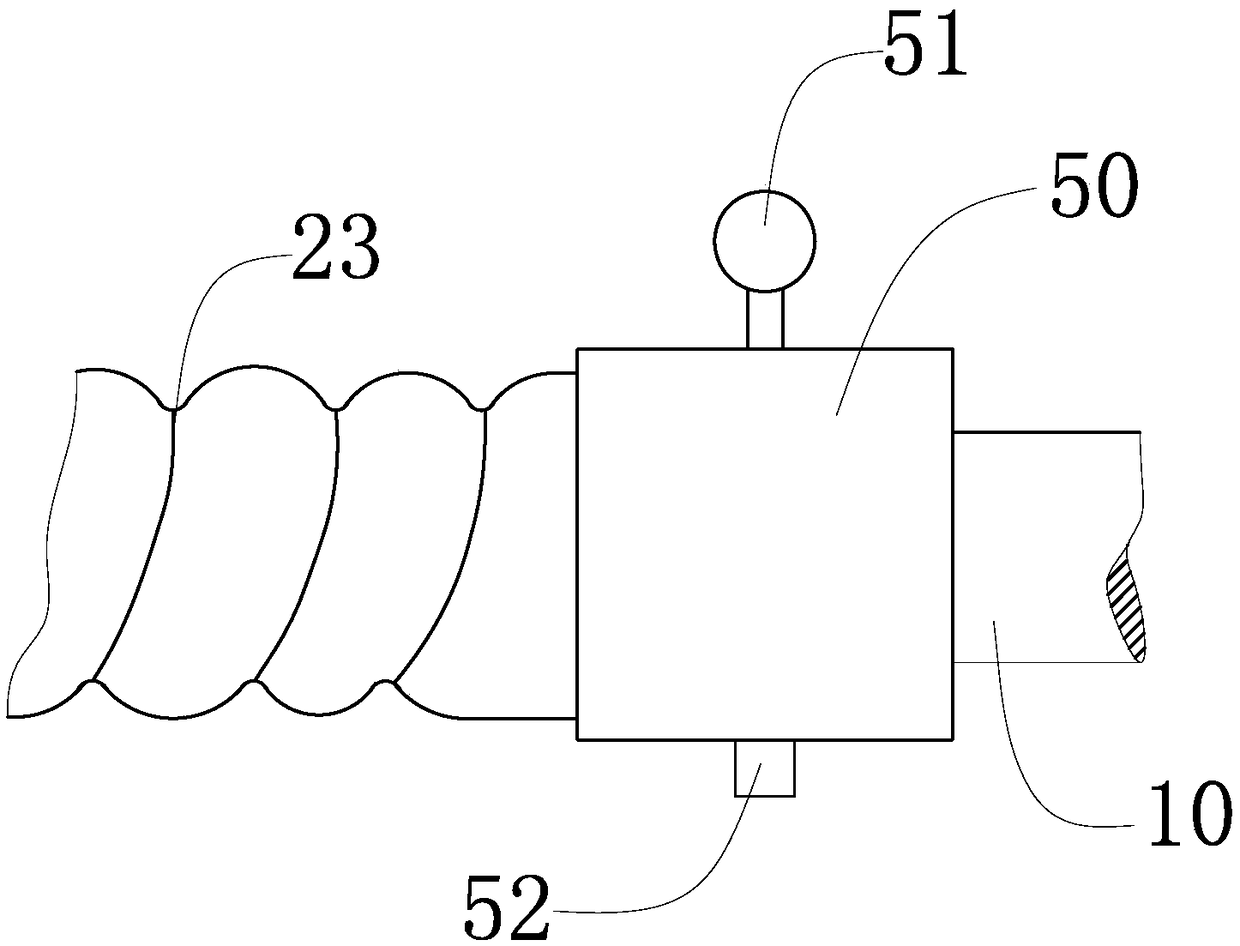

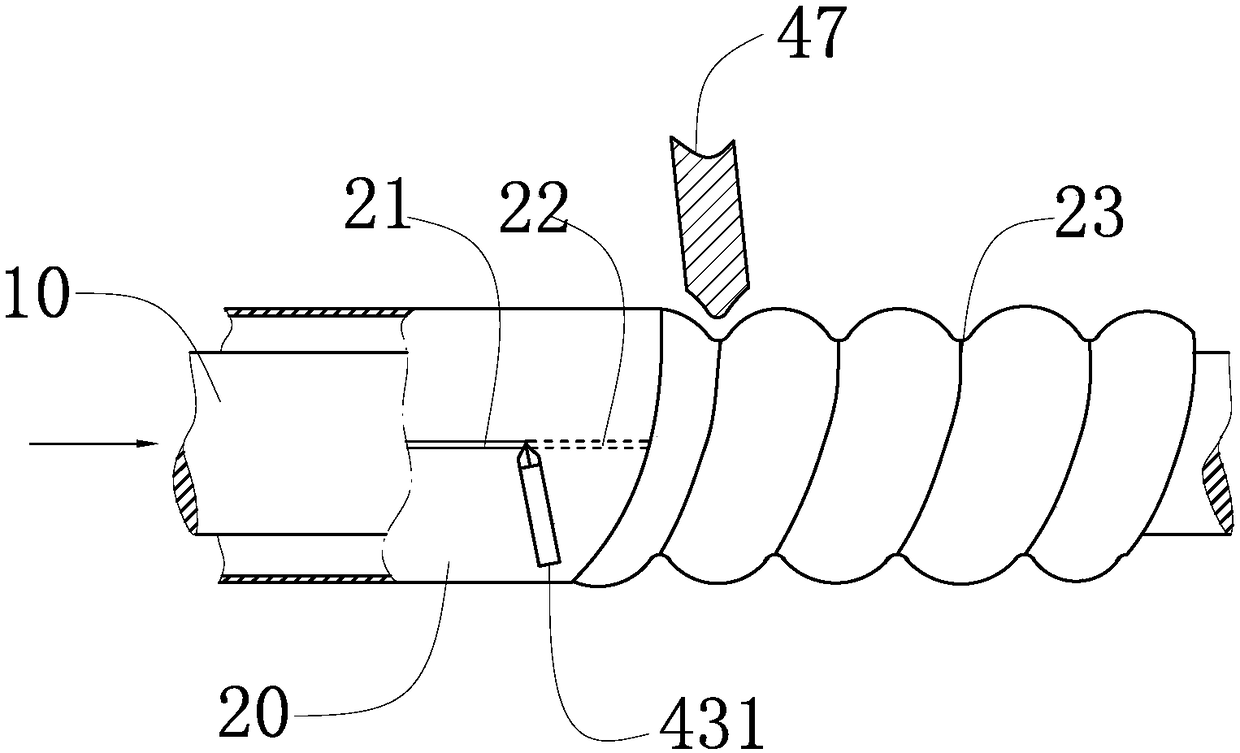

[0047] like Figure 1 to Figure 2 As shown, a spiral armored cable includes a cable body 10 and a metal armor layer 20 wrapped around the outer periphery of the cable body 10 . The metal armor layer 20 is provided with an axial joint 21 (that is, when the metal strip is bent, the joints on both sides), and the axial joint 21 is the welding part 22. When the metal strip is bent into a tubular shape, when the welding head 431 is in the shape of a tube. Weld the connection. The welding part 22 is in the form of full welding, and there should be no defects such as pores and cracks, so as to ensure that the metal round tube 25 does not leak. The outer circumference of the metal armor layer 20 is provided with a spiral indentation 23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com