Manufacturing method of flash memory embedded into logic circuit

A manufacturing method and a technology of logic circuit area, applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of pinhole effect, easy short circuit of logic transistor, low yield rate of flash memory, etc. The effect of a large process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As mentioned in the background, in the prior art, when a flash memory, a high-voltage floating-gate transistor, and a logic transistor are manufactured simultaneously, the channel of the logic transistor may have a pinhole effect, and adjacent logic transistors may be easily short-circuited. In view of the above technical problems, the inventors have found the following three reasons after analysis.

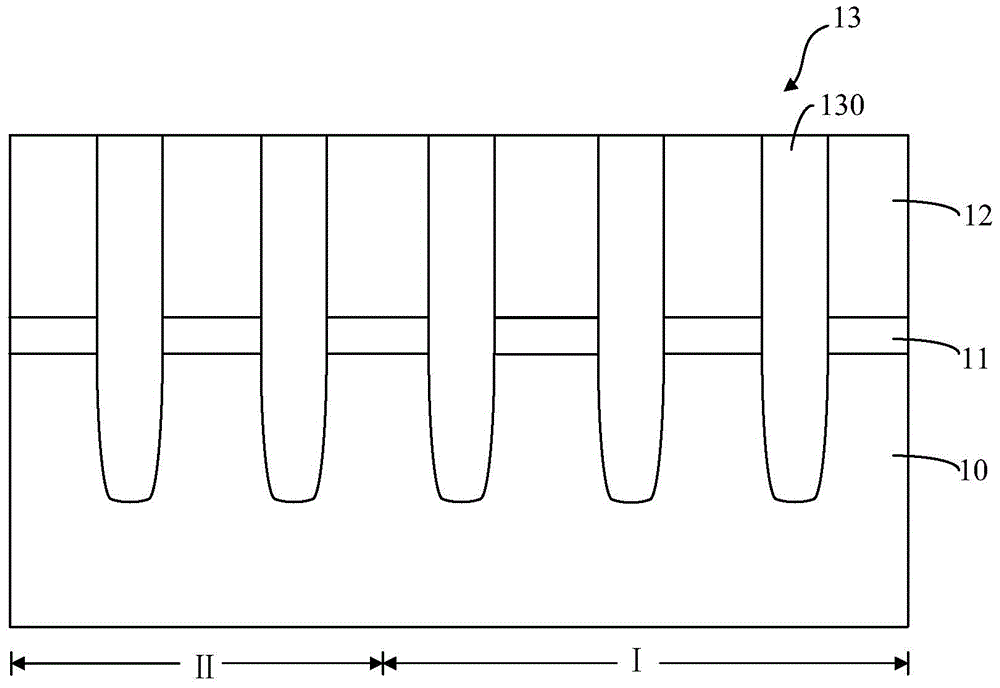

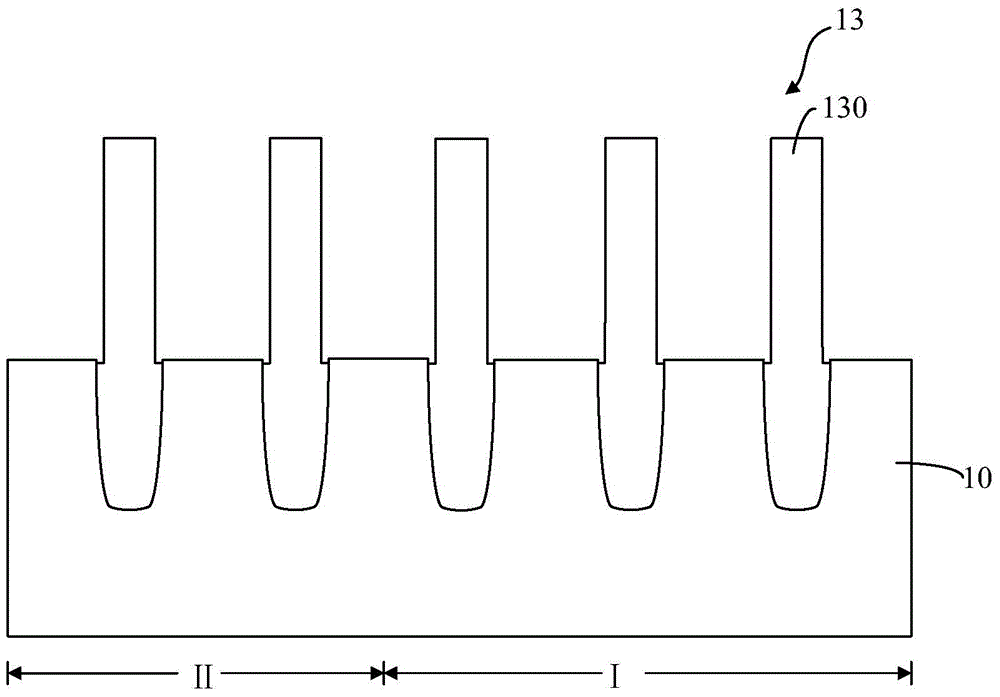

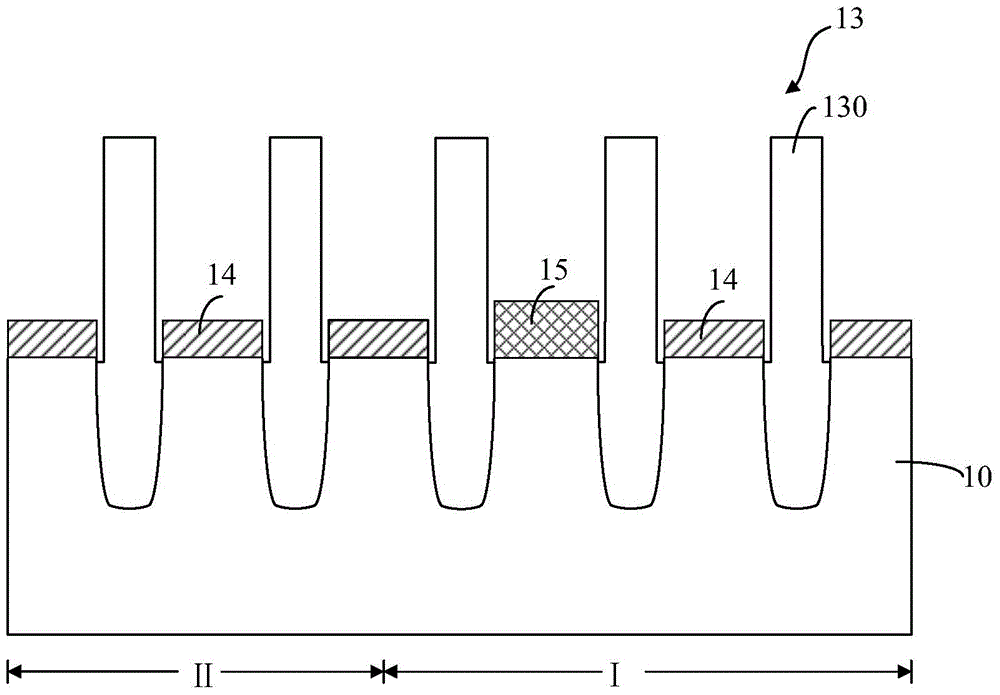

[0037] 1) Reference Figure 1 to Figure 3 As shown, in order to form the tunnel insulating layer required for the flash memory and the high-voltage floating gate transistor in the core cell area I, the buffer oxide layer 11 and the silicon nitride layer 12 stacked on the surface of the semiconductor substrate 10 from bottom to top After the shallow trench isolation structure 13 is formed, the silicon nitride layer 12 in the core cell region I and the logic circuit region II is removed first, and then the buffer oxide layer 11 is removed. The buffer oxide layer 11 is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com