A display substrate, its manufacturing method, display panel and display device

A technology for a display substrate and a manufacturing method, applied in the fields of the manufacturing method, display substrate, display panel, and display device, capable of solving problems such as poor undercut of pixel electrodes and drain electrodes, reducing the risk of poor undercut, and improving product quality rate, to avoid the effect of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A display substrate, a manufacturing method thereof, a display panel and a display device provided by the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

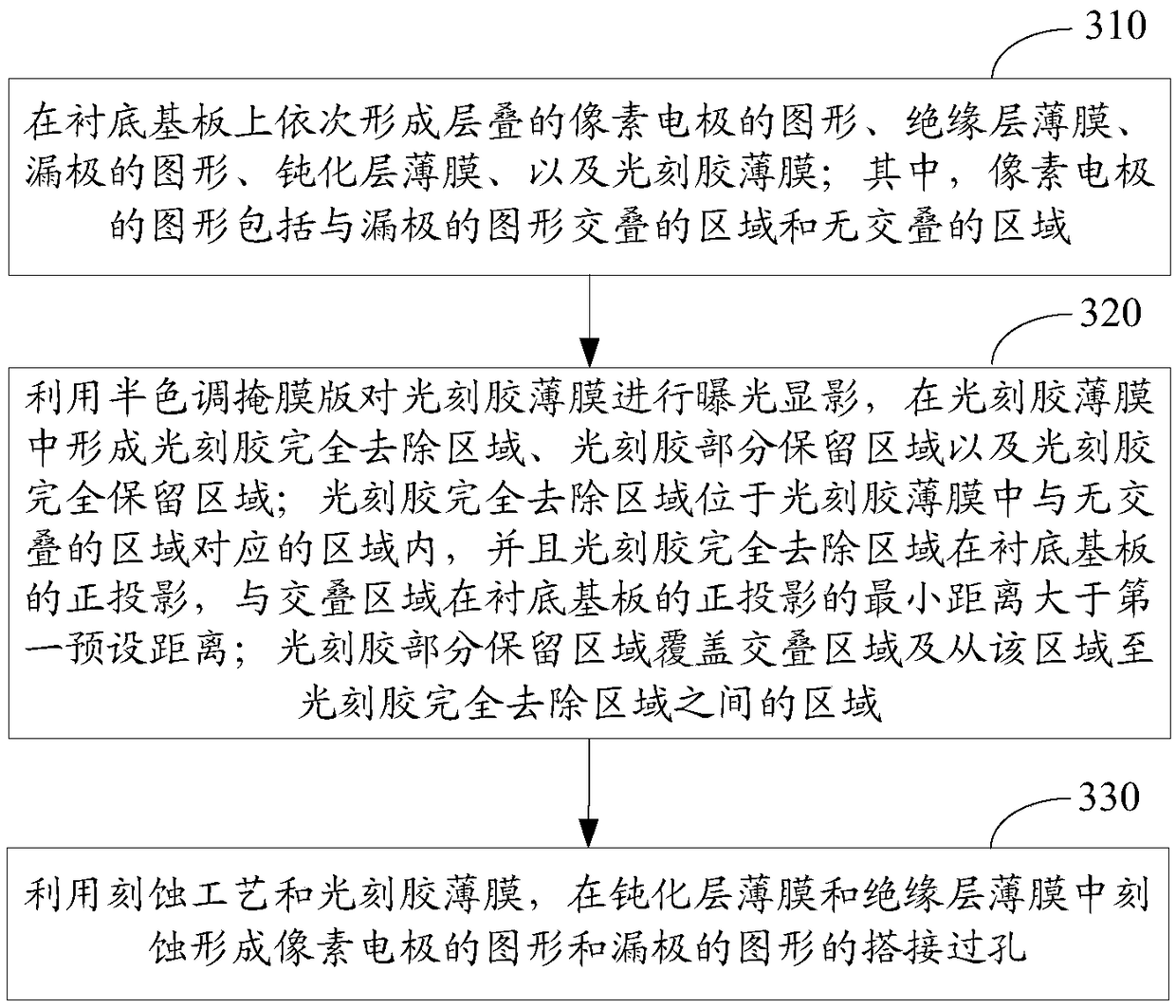

[0028] In an embodiment of the present invention, a method for manufacturing a display substrate is provided, such as image 3 As shown, at least the following steps are included:

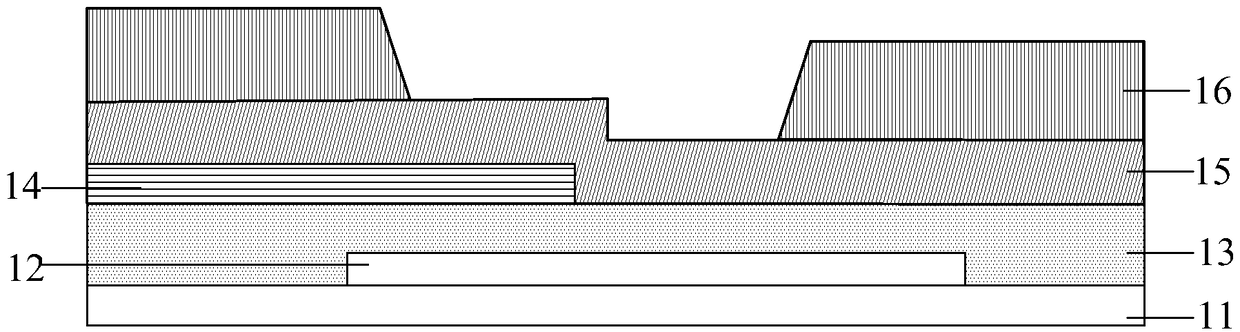

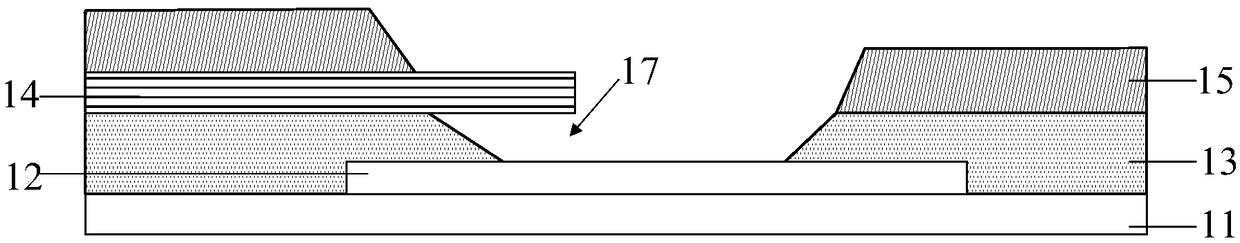

[0029] Step 310, sequentially forming a layered pixel electrode pattern, an insulating layer film, a drain pattern, a passivation layer film, and a photoresist film on the base substrate; overlapping regions and non-overlapping regions.

[0030] Step 320, using a half-tone mask to expose and develop the photoresist film, forming a photoresist completely removed area, a photoresist partially reserved area, and a photoresist completely reserved area in the photoresist film; the photoresist is completely The removal area is located in the area corresponding to the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com