A method for controlling the optical properties of synthesized perovskite by ion implantation technology

A technology of ion implantation and technology control, which is applied in the field of ion implantation technology to control the optical properties of perovskite after synthesis, which can solve problems such as difficult adjustment, and achieve the effect of improving basic research, broad application prospects, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

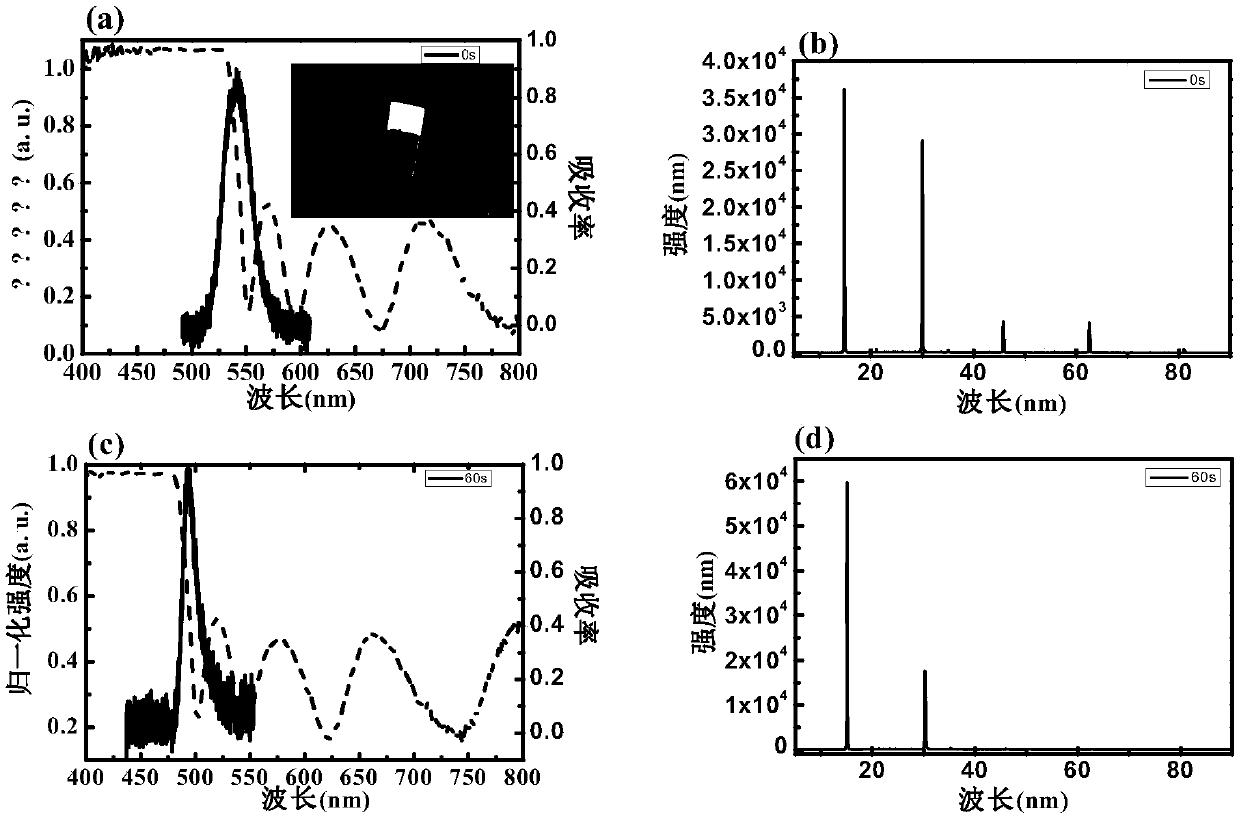

[0030] The first step in controlling the fluorescence and lasing emission of lead halide perovskites is to synthesize high-quality single-crystal perovskite microstructures. Here we synthesize CH 3 NH 3 PbBr 3 The perovskite is a one-step solution precipitation method commonly used in the prior art. This synthetic method can produce a large amount of high-quality CH 3 NH 3 PbBr 3 Microwires and Microblocks.

[0031]The size of the perovskite crystal microblocks we synthesized ranges from several microns to hundreds of microns in length, several microns to tens of microns in width, and hundreds of nanometers to several microns in thickness. The size of the perovskite microwire is several micrometers to tens of micrometers long, hundreds of nanometers to several micrometers wide, and hundreds of nanometers to several micrometers thick. In this example, we choose a micron block as an example to detail its corresponding optical properties. The corresponding scanning electr...

Embodiment 2

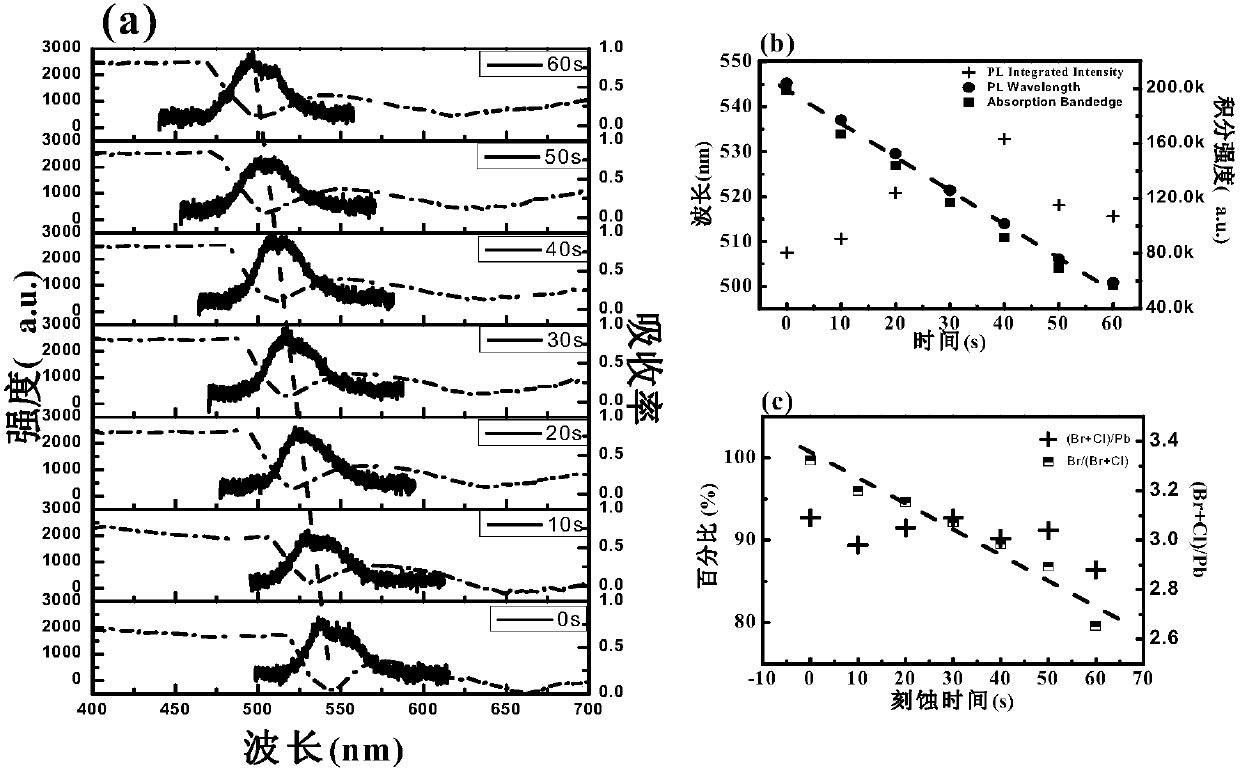

[0034] To confirm changes in chemical composition, we performed energy-dispersive X-ray spectroscopy (EDS) analysis. The ratio of Br / Pb in the as-grown perovskite is about 75 / 25, which is similar to that of PbBr 3 The stoichiometry matches. Then, the samples were etched in ICP chlorine gas for 60 s, the ratio of bromide / lead ions was changed to about 59.1 / 25, while the ratio of chloride / lead ions was increased from 0 to 15.2 / 25. figure 2 (c) represents the percentage of bromide and chloride ions in the perovskite microblocks as a function of etching time. Here all etching conditions are the same, as figure 2 As shown in (c), as the etching time increases, the ratio of (Br+Cl) / Pb remains basically unchanged, while the ratio of Br / (Br+Cl) decreases linearly. It shows that the bromide ion is decreasing and the chloride ion is increasing but their total amount remains unchanged. These results clearly demonstrate the behavior of chloride ions replacing bromide ions during etc...

Embodiment 3

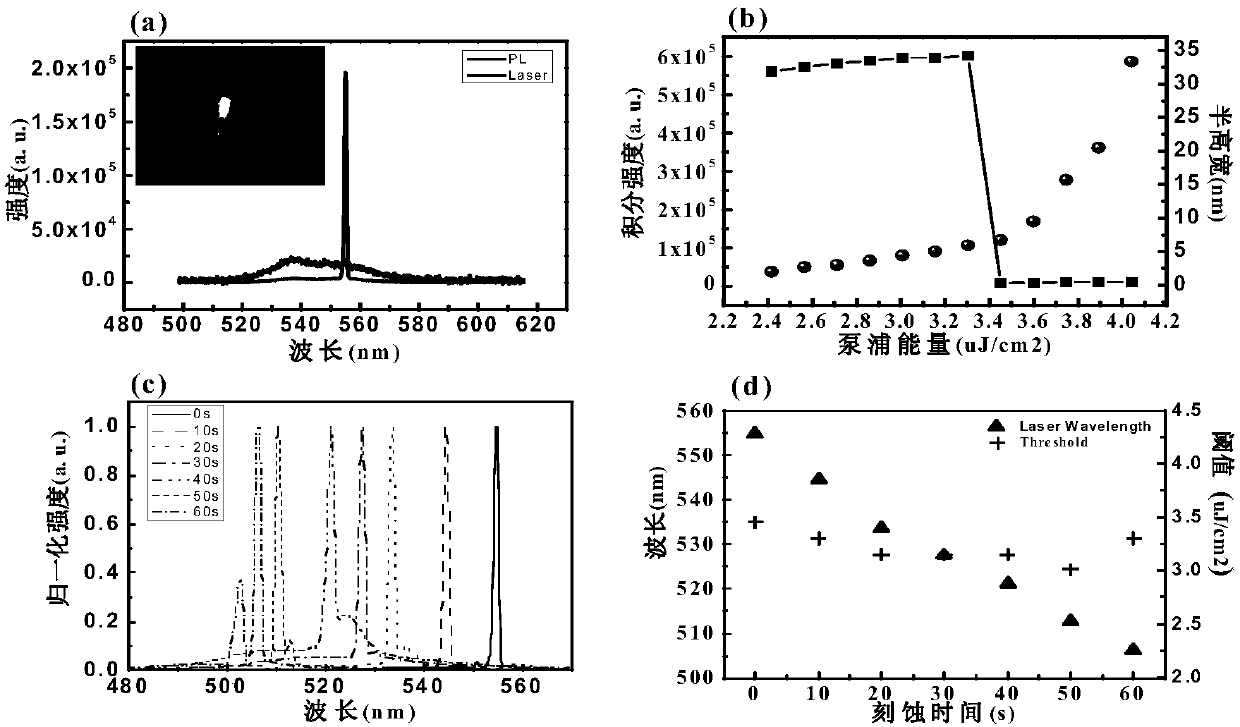

[0038] The most unique property of this technique of controlling the optical properties of as-synthesized perovskite crystals is that different locations of the same sample can be individually controlled, which is almost impossible in conventional solution processing techniques. To illustrate this advantage, we used electron beam lithography to etch another micron block and investigated the corresponding stimulated emission properties. A 300 nm e-beam resist of polymethyl methacrylate (PMMA) was spin-coated on the microblock and half the area was exposed with an e-beam. After developing in MIBK (Methyl Isobutyl Ketone, methyl isobutyl ketone), half of the microblock is still coated with polymethyl methacrylate and the other half is exposed to air, as Figure 4 The SEM image of the perovskite microblock is shown. The sample was then etched in the ICP for 30 seconds, Figure 5 Spectra obtained by pumping at different positions of perovskite microblocks half-covered with PMMA a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com