Coating device for high-temperature resistant multilayer composite lithium-ion battery separator

A lithium-ion battery and multi-layer composite technology, which is applied in the direction of batteries, secondary batteries, battery pack components, etc., can solve the problems of high temperature resistance and heat resistance shrinkage that cannot meet the requirements, and achieve stable product quality and large Economic and social benefits, high-quality finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

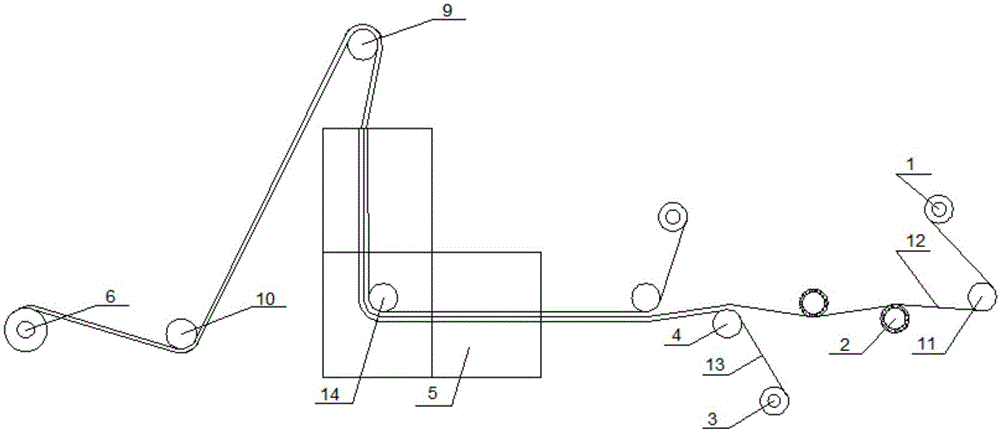

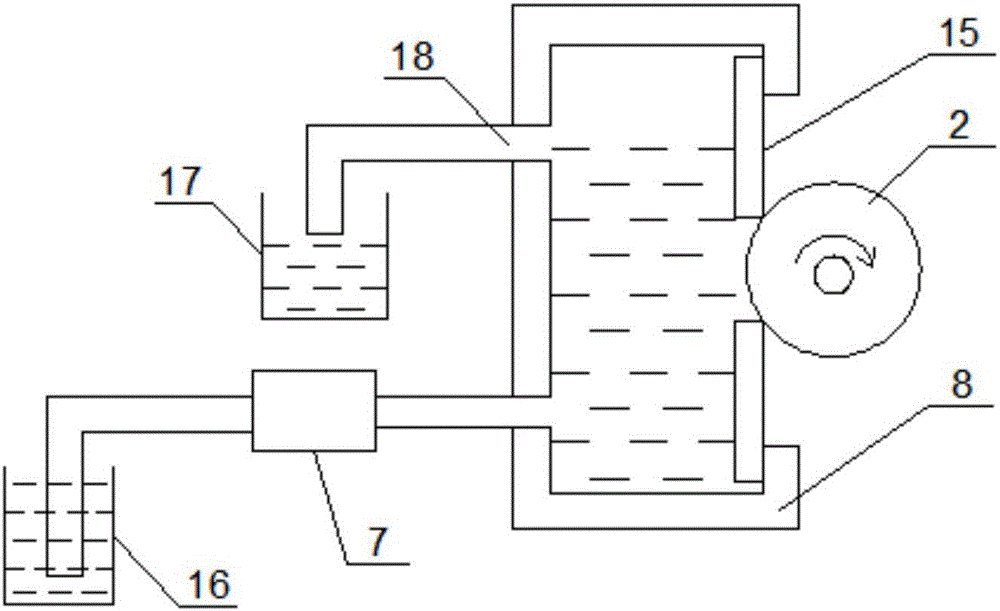

[0016] The invention relates to a coating device for a high-temperature-resistant multi-layer composite lithium-ion battery diaphragm. The coating device includes a base film unwinding shaft 1, a glue roller 2, a heating and drying mechanism, and a winding shaft 6 arranged in sequence. A base film 12 is wound on the film unwinding reel 1, one end of the base film 12 protrudes from the base film unwinding reel and is wound on the rewinding reel 6, the surface of the gluing roller 2 is provided with a coating slurry, the gluing roller 2 is heated and dried A composite film unwinding mechanism is added between the mechanisms, and the glue roller 2 and the composite film unwinding mechanism are arranged one by one on the outside of the same film surface of the base film 12 to form a bonding unit for the composite film 13. The bonding unit is arranged on the base film 12 Two groups on the outer sides of the two film surfaces, the composite film unwinding mechanism includes a composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line speed | aaaaa | aaaaa |

| Line speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com