Separator for non-aqueous secondary battery

A secondary battery, non-aqueous technology, used in battery pack parts, separators/films/diaphragms/spacers, circuits, etc. To achieve the effect of reducing polarization resistance, improving adhesion, and facilitating diffusion and conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present application also relates to the preparation method of the lithium-ion battery diaphragm, which at least includes the following steps: adding adhesive and ceramic material particles to an organic solvent to prepare a coating liquid, coating the coating liquid on a substrate, and then immersing the In the coagulation solution, a substrate with a coating is formed, and the wet film thickness of the coating is 1-3 μm, preferably 1.4-2.2 μm.

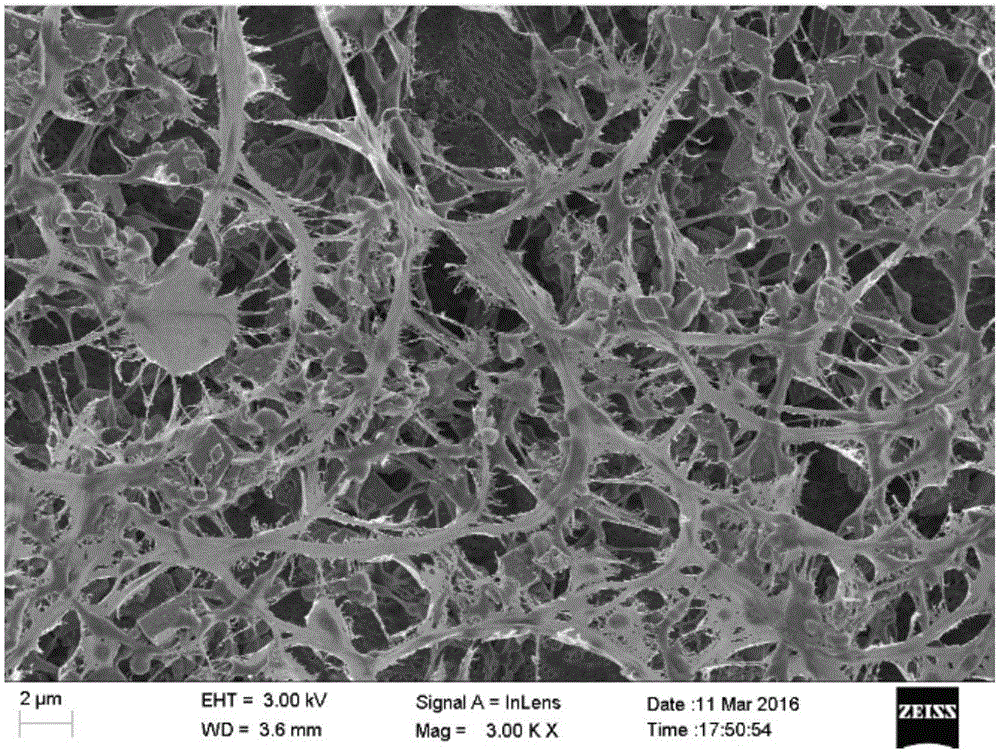

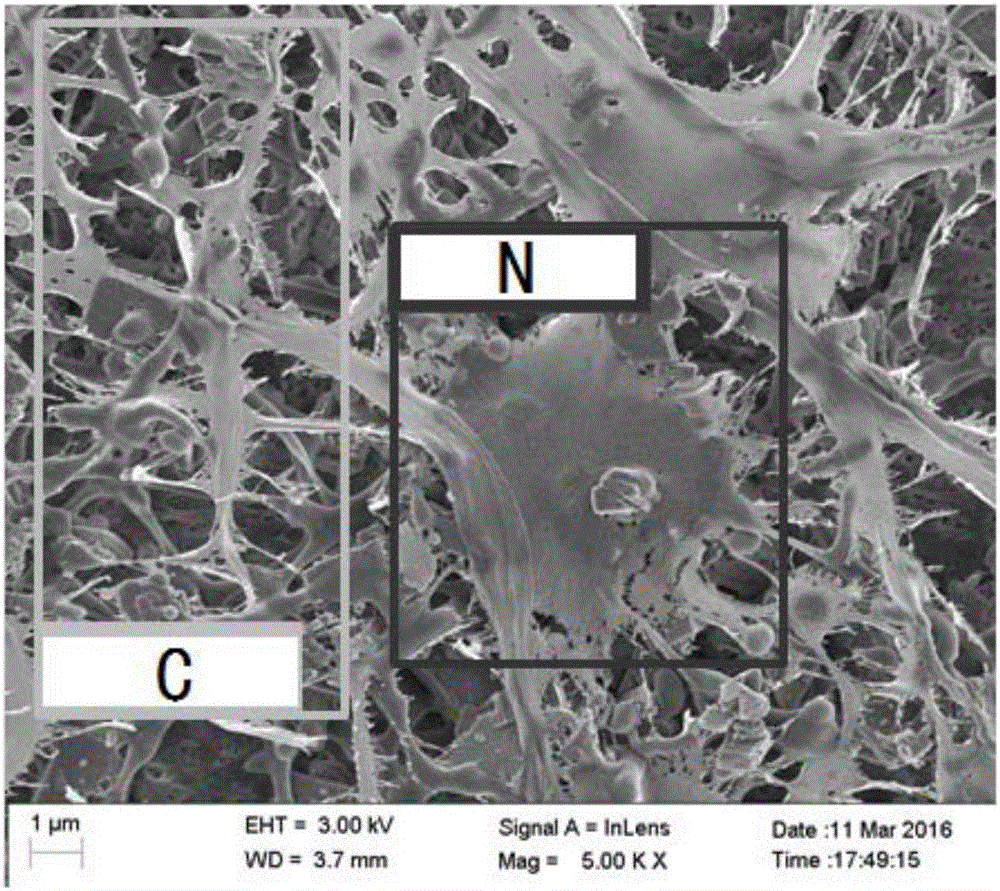

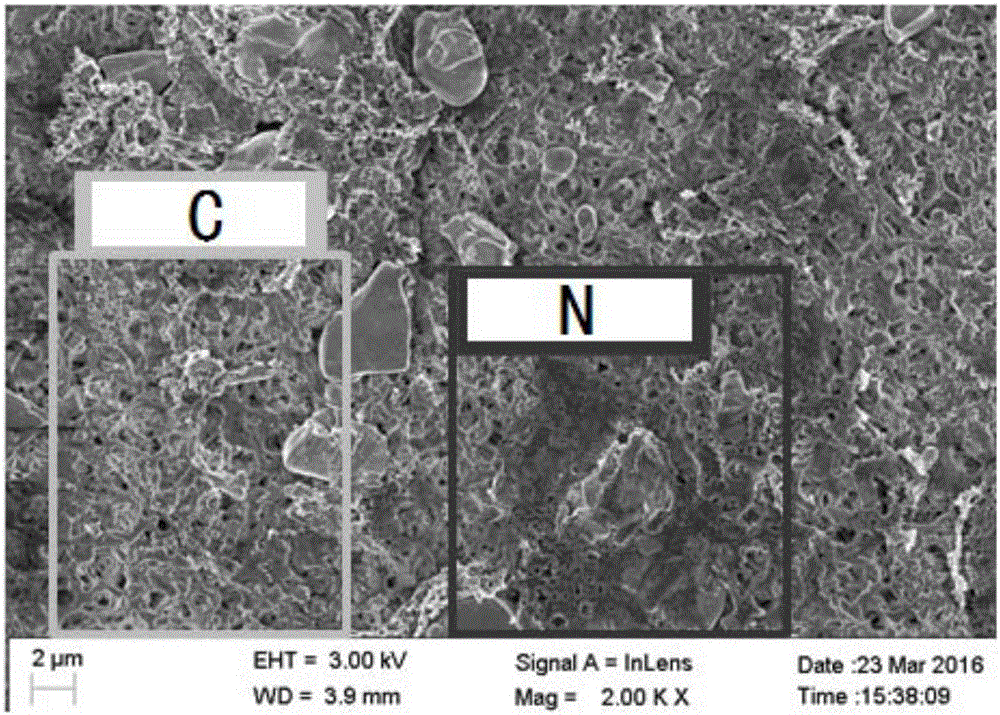

[0048] This application uses the principle of phase inversion method to prepare the coating of the diaphragm, wherein the solvent used is oily, PVDF can be dissolved in the solvent; the non-solvent is water-based, PVDF is insoluble in the non-solvent; and the solvent and the non-solvent are miscible. After PVDF is dissolved in an oily solvent, it is mixed with ceramics to form a coating solution. The coating solution is coated on the isolation film, and the isolation film is immersed in a non-solvent to exchange the solvent...

Embodiment 1

[0056] A diaphragm for a non-aqueous secondary battery comprises a diaphragm substrate and a coating attached to the surface of the substrate, and the surface layer of the coating includes a bonding area and an electrolyte diffusion area.

[0057] The preparation method of the membrane of the present application is:

[0058] 1. Dissolve the PVDF resin KYNAR2851 produced by ARKEN in the solvent dimethylacetamide to make a coating solution. The solid content of the resin is 5%, and the mass ratio of resin to solvent is 5:93; add ceramic particle materials, ceramic The parameters such as the type, particle size and content of the granular material are shown in Table 1;

[0059] 2. The coating solution is coated on a porous substrate (TN0901: SK company, 9 μm thickness, porosity 43%) by an OSB-17 wire bar to form a coating solution coating, and the ratio of the coating to ceramic material particles is as follows As shown in Table 1;

[0060] 3. Immerse the coating liquid coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com