Distributed type bilateral liquid-cooling system and flow control method for power battery system

A power battery and flow control technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as battery temperature rise, low cooling efficiency, and difficulty in meeting heat dissipation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

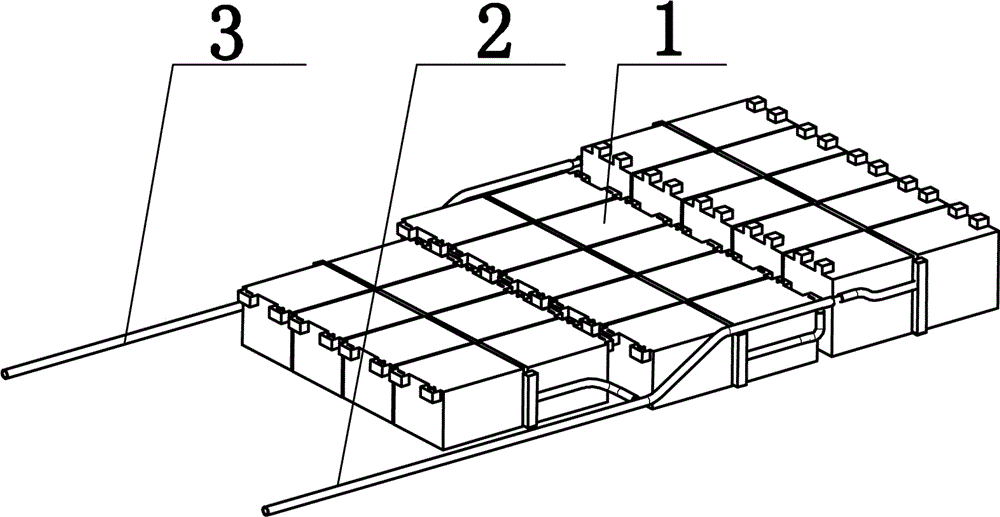

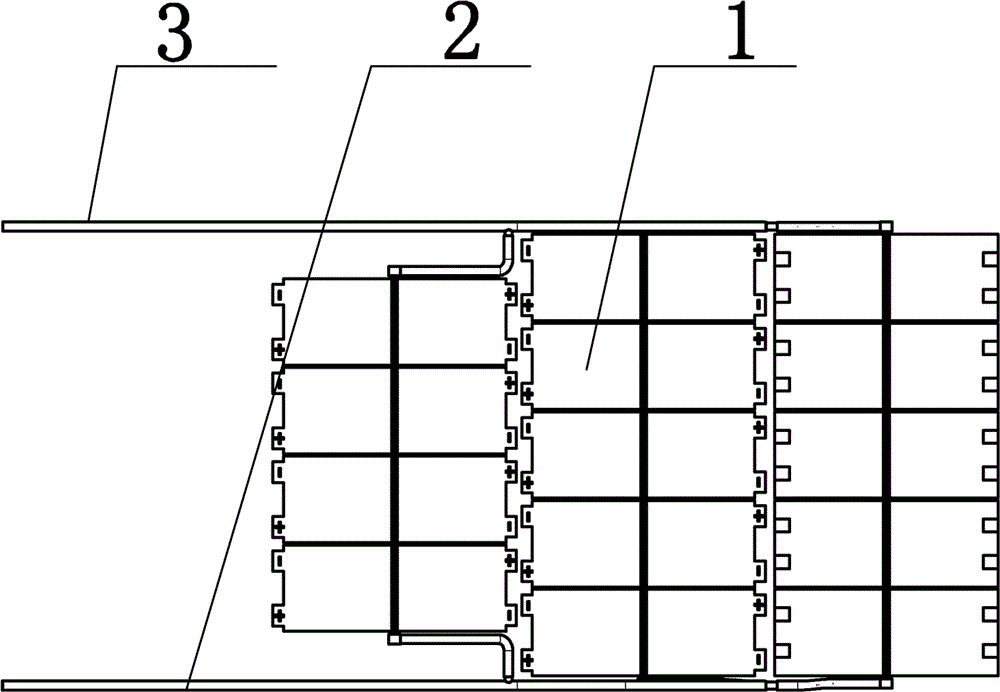

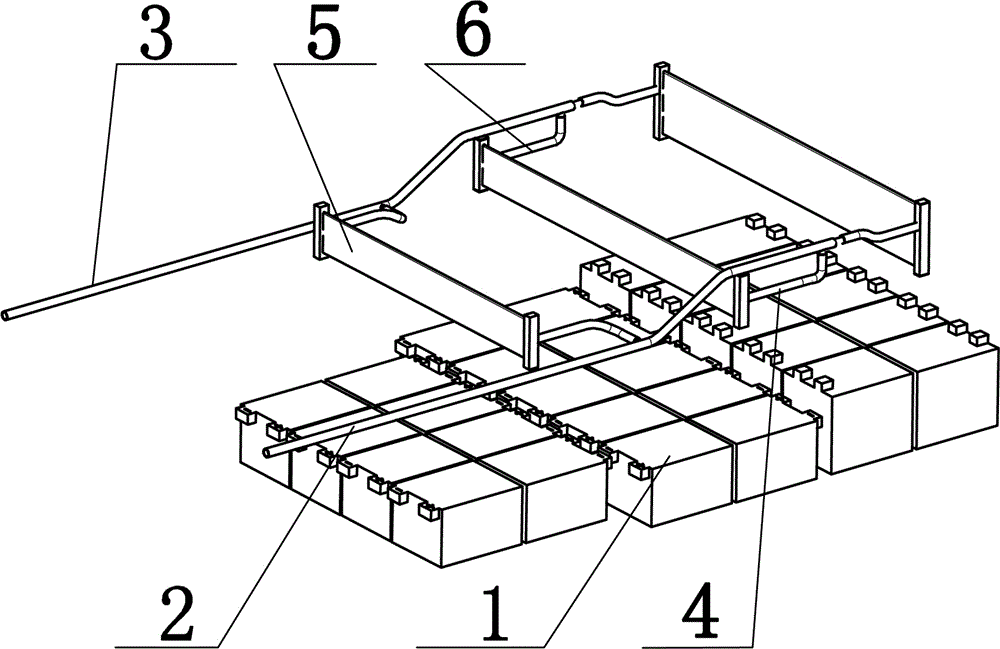

[0031] As shown in the figure, the present invention relates to a distributed double-sided liquid cooling system for a power battery system. The power battery system includes the first to n battery module groups 1 arranged side by side in sequence; the liquid cooling system includes The cooling liquid input pipe 2, the cooling liquid output pipe 3, and the 1st to n liquid cooling channels arranged between the cooling liquid input pipe 2 and the cooling liquid output pipe 3, the 1st to n liquid cooling channels and the first 1 to n battery module groups 1 are set correspondingly; the coolant input pipe 2, the 1st to n liquid cooling channels and the coolant output pipe 3 are respectively the 1st to n liquid cooling circuits, and the 1st to n The n liquid cooling channels are in spatial communication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com