High-reliability high-voltage high-current electromechanical servo driver

An electromechanical servo and high current technology, which is applied in the field of electromechanical servo drives and servo drives, can solve the problems of reduced reliability, large collector current change rate, unfavorable system high reliability operation, etc., achieve LDC reduction, and realize the peak value of fluctuating voltage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

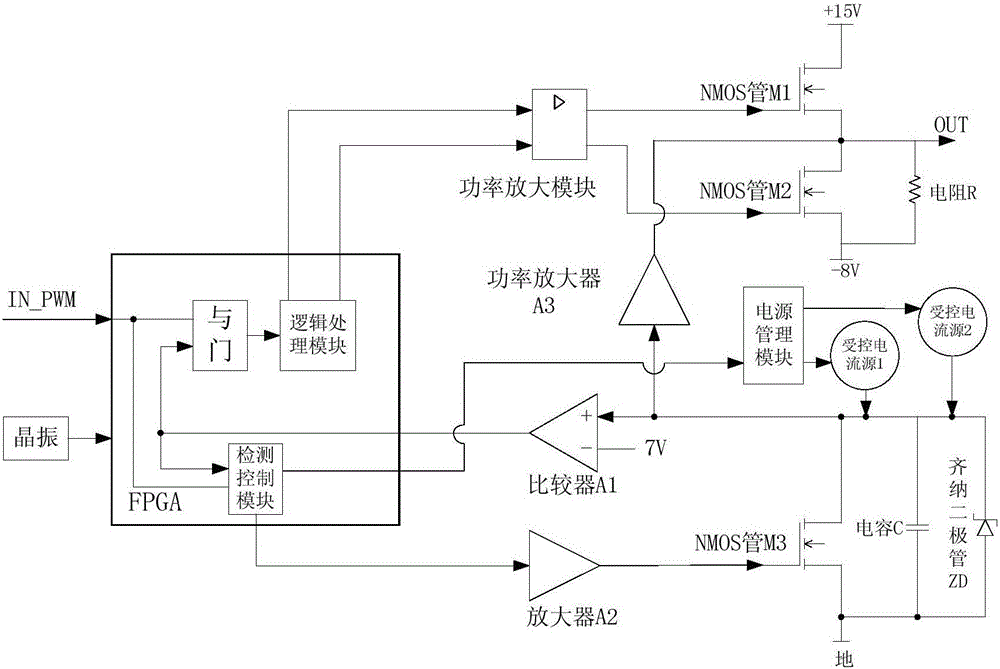

[0044] The basic idea of the present invention is: a high-reliability high-voltage high-current electromechanical servo drive, in which the peak voltage generated between the collector and the emitter of the IGBT during the turn-off process can be effectively suppressed, and at the same time, due to the The peak value of the fluctuating voltage caused by excessive bus inductance can also be suppressed, ensuring the high reliability of the electromechanical servo drive. The IGBT drive circuit does not directly output -8V level for shutdown after receiving a low-level input, but It is to output a certain intermediate level between +14.5V and +7V for a short period of time, such as +9V, and then output -8V to turn off. Since the collector current of the IGBT is proportional to the turn-on voltage of the gate, the gate level of +9V will limit the collector current of the IGBT to a lower value, and then the drive circuit will output -8V to turn off the IGBT. The current change ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com