Processing method of brewing instant integral-flower tremella

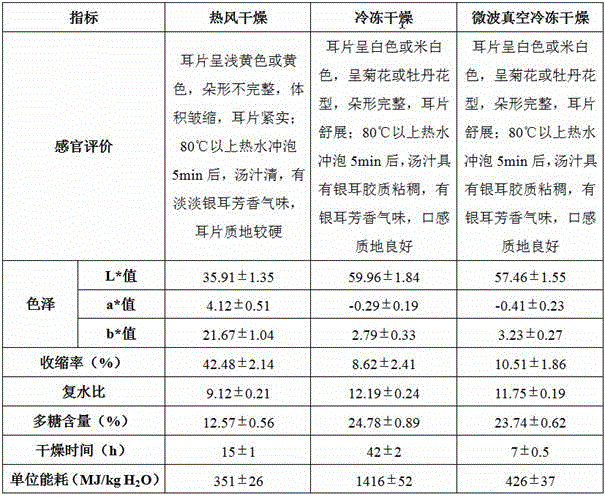

A processing method and technology of white fungus, which is applied in food processing, food preservation, food drying, etc., can solve the problems that the shape and original taste of white fungus cannot be reflected, the viscosity of the soup is not enough, and the processing is difficult, so as to avoid enzymes Promoting reaction and microbial action, making up for long operating time and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Cleaning: select fresh, whole white fungus free of diseases and insect pests, remove the base of the ear, and clean to remove impurities;

[0024] 2) Blanching: Blanch the washed whole white fungus in hot water at 80°C for 2 minutes, remove and drain;

[0025] 3) Pre-freezing: Cool the whole white fungus with the original shape after draining to room temperature, and then pre-freeze at -40°C for 10 hours, so that the central temperature of the white fungus is controlled below -20°C;

[0026] 4) Microwave vacuum freeze-drying: put the pre-frozen whole white fungus into the microwave vacuum freeze dryer quickly, and dry it in two stages. The first stage: the pressure is 180Pa, the microwave power is 350 W / Kg, and the drying time 5 hours; the second stage: the pressure is 10Pa, the microwave power is 100 W / Kg, and the drying time is 2 hours; the surface temperature of the white fungus during the drying process is 50°C; the water content of the white fungus product obtai...

Embodiment 2

[0028] 1) Cleaning: select fresh, whole white fungus free of diseases and insect pests, remove the base of the ear, and clean to remove impurities;

[0029] 2) Blanch: Blanch the washed whole white fungus in hot water at 100°C for 1 minute, remove and drain;

[0030] 3) Pre-freezing: Cool the whole white fungus with the original shape after draining to room temperature, and then pre-freeze at -40°C for 3 hours, so that the central temperature of the white fungus is controlled below -20°C;

[0031] 4) Microwave vacuum freeze-drying: put the pre-frozen whole white fungus into the microwave vacuum freeze dryer quickly, and dry it in two stages. The first stage: the pressure is 120Pa, the microwave power is 200 W / Kg, and the drying time 3 hours; the second stage: the pressure is 100Pa, the microwave power is 150 W / Kg, and the drying time is 4 hours; the surface temperature of the white fungus during the drying process is 30°C; the water content of the white fungus product obtained...

Embodiment 3

[0033] 1) Cleaning: select fresh, whole white fungus free of diseases and insect pests, remove the base of the ear, and clean to remove impurities;

[0034] 2) Blanch: Blanch the washed whole white fungus in hot water at 90°C for 2 minutes, remove and drain;

[0035] 3) Pre-freezing: Cool the whole white fungus with the original shape after draining to room temperature, and then pre-freeze at -40°C for 6 hours, so that the central temperature of the white fungus is controlled below -20°C;

[0036] 4) Microwave vacuum freeze-drying: put the pre-frozen whole white fungus into the microwave vacuum freeze dryer quickly, and dry it in two stages. The first stage: the pressure is 150Pa, the microwave power is 250 W / Kg, and the drying time 4 hours; the second stage: the pressure is 50Pa, the microwave power is 120 W / Kg, and the drying time is 3 hours; the surface temperature of the white fungus during the drying process is 40°C; the water content of the white fungus product obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com