Azilsartan kaMedoxoMil solid dispersoid preparation and preparation method thereof

A technology of azilsartan medoxomil and solid dispersion, which is applied in the field of azilsartan medoxomil potassium salt solid dispersion preparation and its preparation, and can solve the problems that Edarbi cannot be replaced in terms of effectiveness, safety and tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

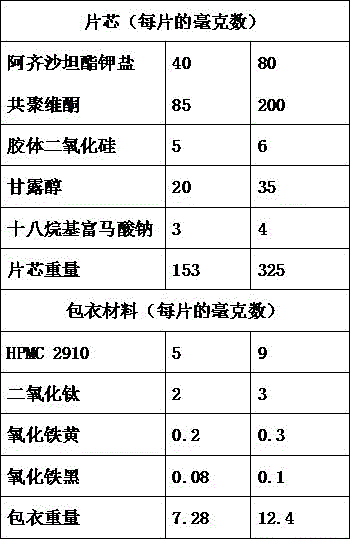

[0040] Embodiment 1: Azilsartan medoxomil potassium salt solid dispersion tablet

[0041] prescription:

[0042] components

parts by weight

Azilsartan medoxomil potassium salt

40

Povidone K30

85

Microcrystalline Cellulose 102

50

20

8

silica

2

Sheet weight

215

[0043] Preparation process: solvent evaporation method

[0044] Dissolve the prescribed amount of azilsartan medoxomil potassium salt and povidone K30 in a solvent of acetone:methanol (1:3), volatilize under reduced pressure in a water bath at 60°C, vacuum degree 0.07-0.08MPa, reduce The organic solvent was recovered under pressure, and after it became viscous, it was dried under reduced pressure for 1 hour, transferred to a vacuum drying oven, dried at 40°C for 48 hours, and then crushed through an 80-mesh sieve to obtain a solid dispersion.

[0045] The prepared solid dispersion was ad...

Embodiment 2

[0046] Embodiment 2: Azilsartan medoxomil potassium salt solid dispersion tablet

[0047] prescription:

[0048] components

parts by weight

Azilsartan medoxomil potassium salt

80

Povidone K30

150

Microcrystalline Cellulose 102

90

20

7

talcum powder

3

Sheet weight

350

[0049] Preparation process: solvent evaporation method

[0050] Take the prescribed amount of azilsartan medoxomil potassium salt and povidone K30, dissolve in methanol: dichloromethane (4:1) solvent, put in water bath at 60°C, vacuum degree 0.07-0.08MPa, and recover organic After the solvent becomes viscous, continue vacuum drying under reduced pressure for 1 hour, transfer to a vacuum drying oven, dry at 40°C for 48 hours, and pass through an 80-mesh sieve to pulverize to obtain a solid dispersion.

[0051] The prepared solid dispersion is added into the prescribed amount of mi...

Embodiment 3

[0052] Embodiment 3: Azilsartan medoxomil potassium salt solid dispersion tablet

[0053] prescription:

[0054] components

parts by weight

Azilsartan medoxomil potassium salt

20

Povidone K30

60

Microcrystalline Cellulose 102

30

10

7

silica

3

Sheet weight

130

[0055] Preparation process: solvent evaporation method

[0056] Dissolve the prescribed amount of azilsartan medoxomil potassium salt and povidone K30 in a solvent of acetone:dichloromethane (3:1), in a water bath at 55°C, with a vacuum of 0.07-0.08MPa, and recover organic matter under reduced pressure. After the solvent becomes viscous, continue vacuum drying under reduced pressure for 3 hours, transfer to a vacuum drying oven, dry at 60°C for 48 hours, and pass through an 80-mesh sieve to pulverize to obtain a solid dispersion.

[0057] The prepared solid dispersion is added to the presc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com