An exhaust gas purification device for kitchen waste

A waste gas purification device and kitchen waste technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of affecting evaporation speed, dealing with peculiar smell, and saturation of water vapor in the barrel, so as to reduce energy consumption and improve Drying speed, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

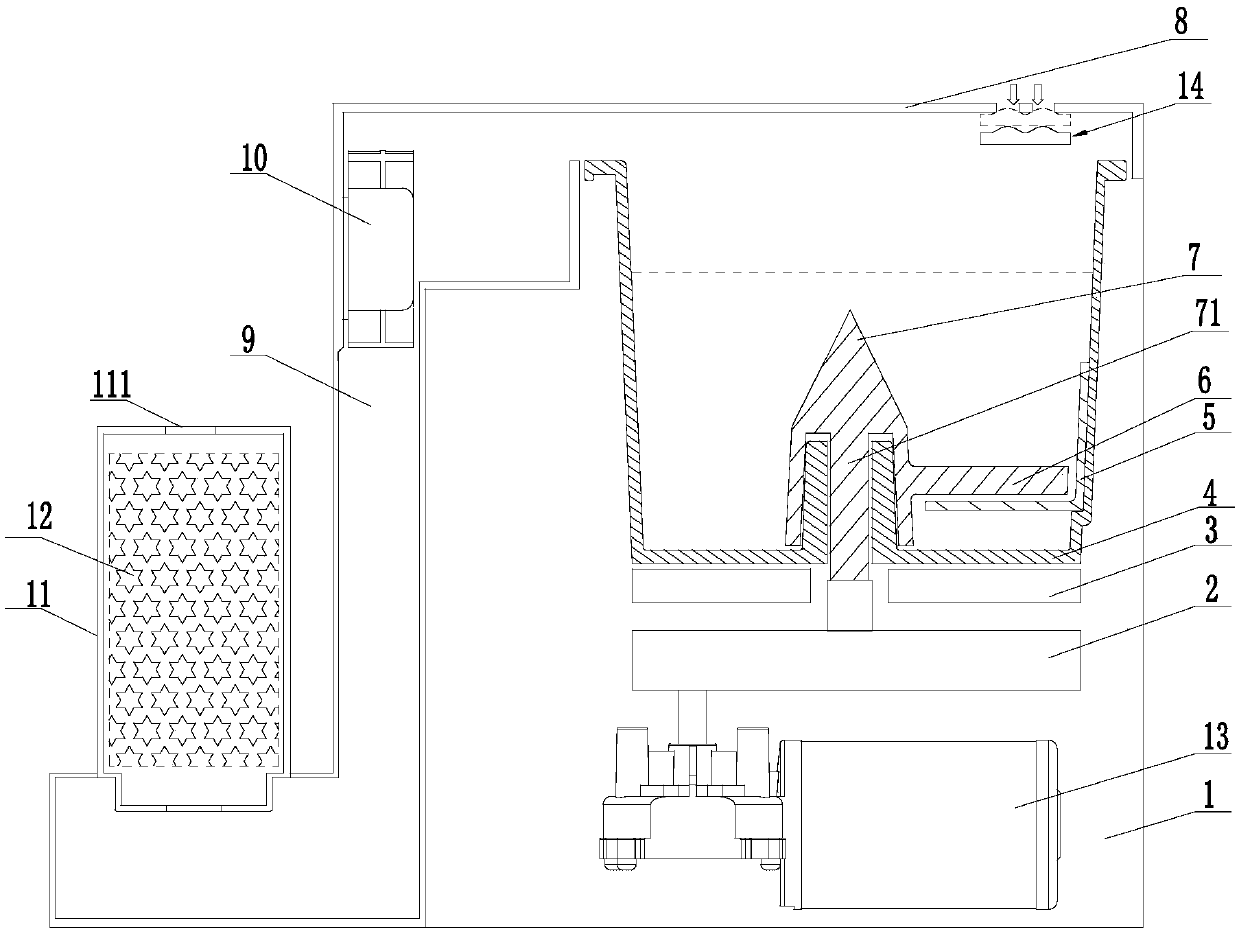

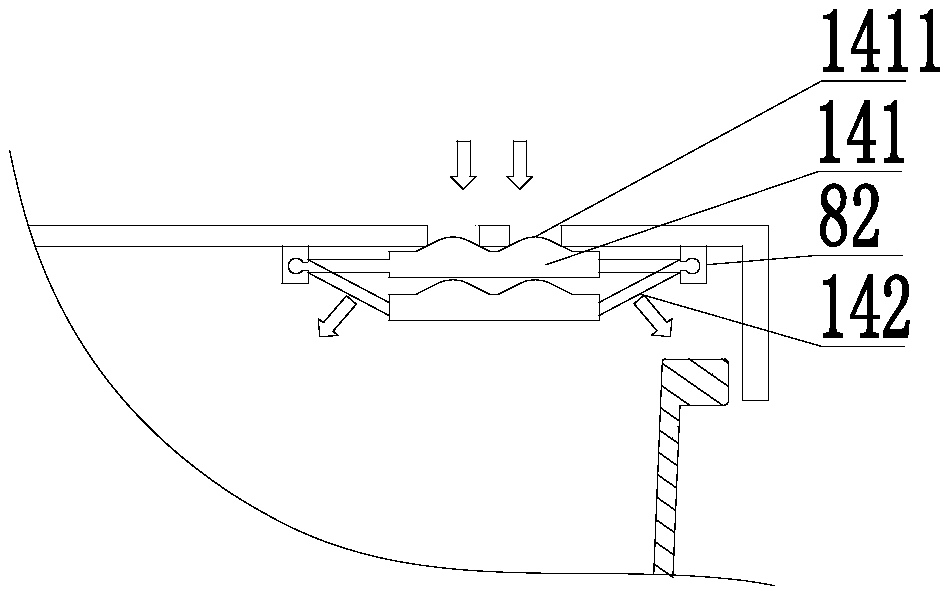

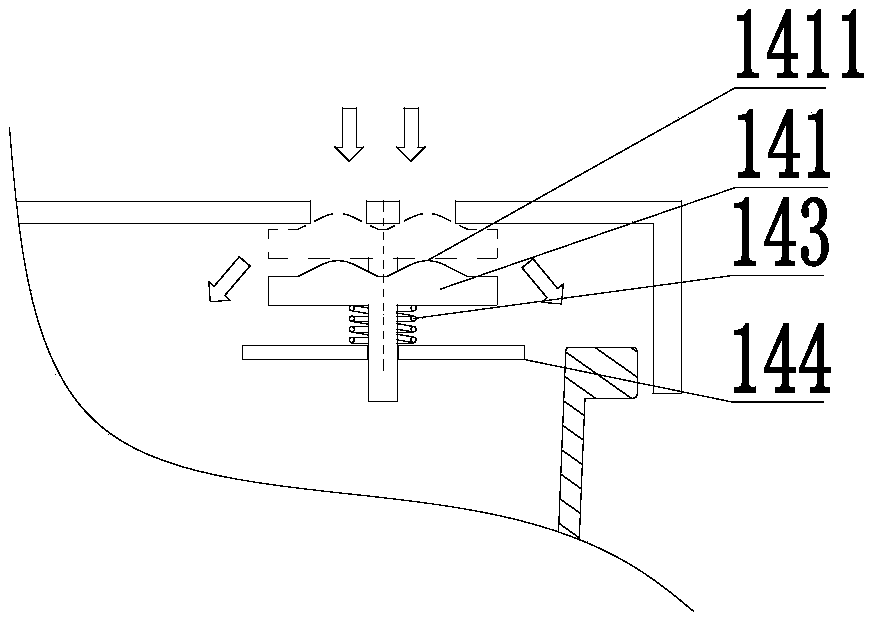

[0027] Such as Figure 1-2 As shown, an exhaust gas purification device for kitchen waste includes an outer barrel 1, a material barrel 4, a guide pipe 9, a heating block 3, a control module, a reduction motor 13, a transmission mechanism 2, a fixed blade 5, a movable blade 6, Spindle 7.

[0028] The material barrel 4 is arranged inside the outer barrel 1, the material barrel 4 is connected with the guide pipe 9, the middle of the guide pipe 9 is provided with an exhaust fan 10, the end of the guide pipe 9 is provided with a filter element 11, and the upper end of the filter element 11 is A vent 111 is provided, and a filter material 12 is provided inside the filter element 111 . Optimally, the filter element 11 also includes a photocatalyst filter net. The photocatalyst filter screen is arranged at the vent 111 (not shown in the figure). Optimally, the filter element 11 is made of activated carbon, the number of the filter elements 11 is two or more, and the filter element...

Embodiment 2

[0048] Such as figure 1 and 3 As shown, a method for processing kitchen waste, the device used in the method includes an outer barrel 1, a material barrel 4, a diversion pipe 9, a heating block 3, a control module, a reduction motor 13, a transmission mechanism 2, a fixed blade 5, Moving blade 6, rotating shaft 7.

[0049] The material barrel 4 is arranged inside the outer barrel 1, the material barrel 4 is connected with the guide pipe 9, the middle of the guide pipe 9 is provided with an exhaust fan 10, the end of the guide pipe 9 is provided with a filter element 11, and the upper end of the filter element 11 is A vent 111 is provided, and a filter material 12 is provided inside the filter element 111 . Optimally, the filter element 11 also includes a photocatalyst filter net. The photocatalyst filter screen is arranged at the vent 111 (not shown in the figure). Optimally, the filter element 11 is made of activated carbon, the number of the filter elements 11 is two or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com