Preparation method for small harvester cutting tool with coating

A technology for cutting tools and coatings, applied in coatings, devices for coating liquids on surfaces, and surface pretreatment, etc., can solve the problems of easy rusting of metal products, achieve good product quality, not easy to rust, and avoid leaks The effect of plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

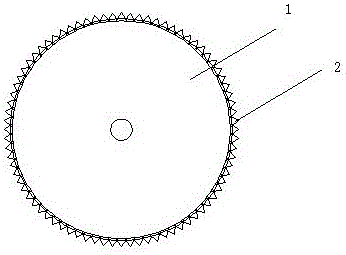

[0013] Examples such as figure 1 Shown, a kind of preparation method of the sprayer cutting tool that has coating, comprises the following steps, pre-treatment, removes after the oil stain, iron and scale sundry on parts cutting tool surface; In the first step, the process of pre-treatment For organic solvent, alkaline cleaning agent degreasing, shot blasting, shot blasting or sandblasting one or more combinations. Coating is to spray or impregnate the parts cutting tool with dacromet solution, and then use centrifugal drying, natural vertical flow and / or brush to remove excess dacromet treatment solution; baking is to apply dacromet on the cutting tool substrate T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com