Semi-independentsuspension structure with integrateddragging arms

An integral, semi-independent technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of insufficient comfort, heavy unsprung weight, etc., to achieve a balance of comfort, low manufacturing costs, and reduced failures rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

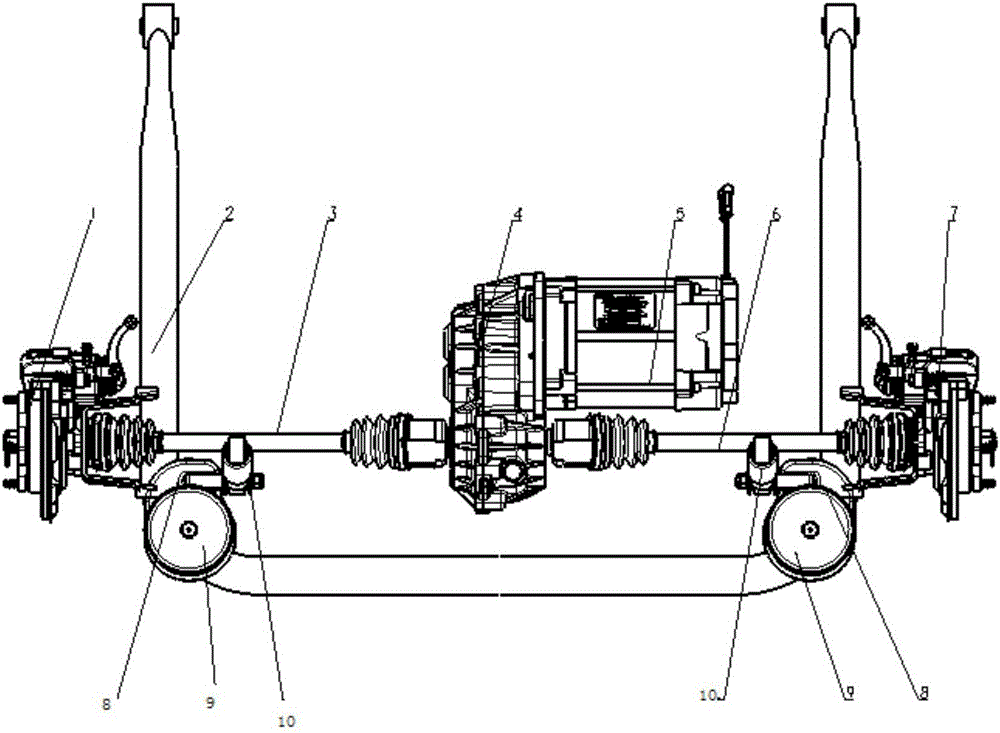

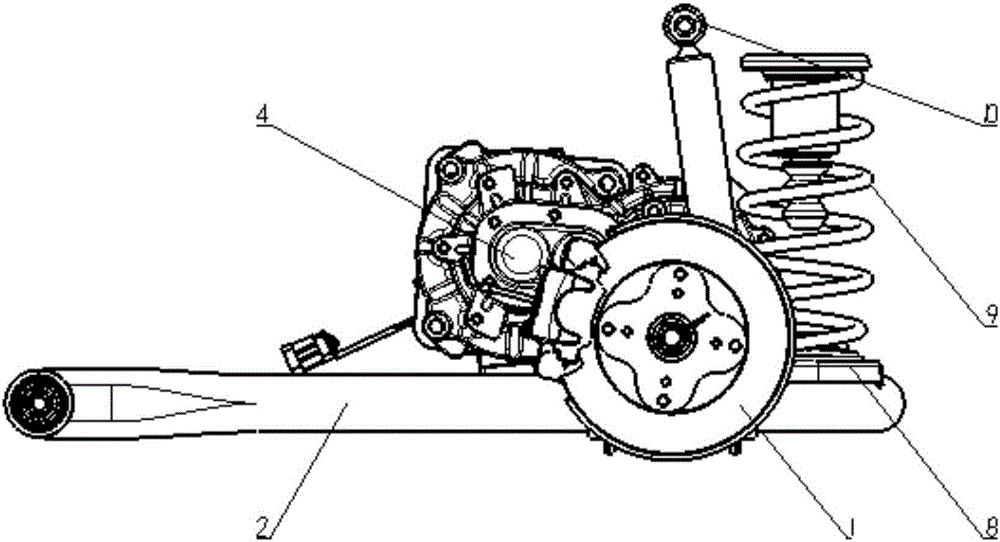

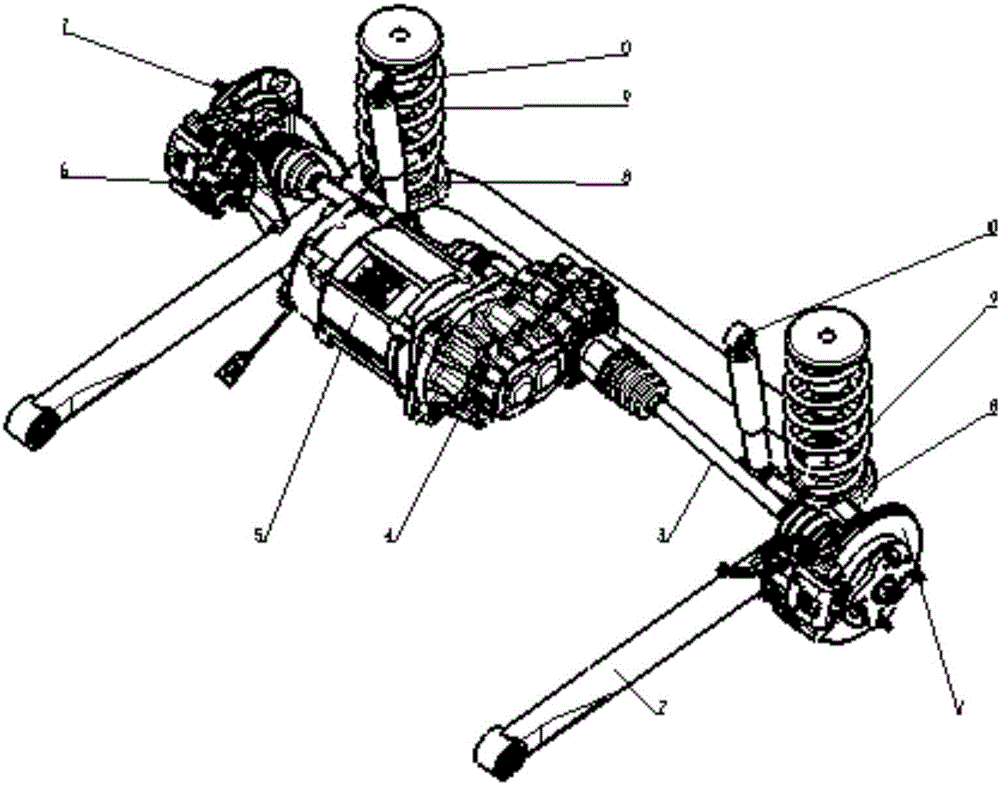

[0022] to combine Figure 1-Figure 6 , the present invention provides an integral trailing arm semi-independent suspension structure, including a left rear brake 1, an integral trailing arm 2, a left constant velocity transmission shaft 3, a reducer and a differential assembly 4, a driving motor 5, a right Constant velocity transmission shaft 6, right rear brake 7, spring seat 8, rear spring 9, rear shock absorber 10.

[0023] The integral trailing arm is a circular tube U-shaped beam structure, which is connected to the frame or the vehicle body through two symmetrical rubber sleeve structures. Preferably, in order to further reduce weight, the integral trailing arm can be made of die-casting aluminum alloys arranged symmetrically. The trailing arm is formed by connecting the round tubes in the middle, and the structure integrates the installation points of the rear brake, rear shock absorber and spring seat. When the beating range of the left and right rear wheels is incons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com