Self-adaption overall overturning conveyor

A conveyor and flip-type technology, which is applied in the field of integral flip-type conveyors, can solve problems such as overweight of the conveyor boom, lack of safety protection devices, and insufficient length of the conveyor arm, so as to reduce the load of the boom, simplify the structure of the gantry, Ease of tensioning and deviation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

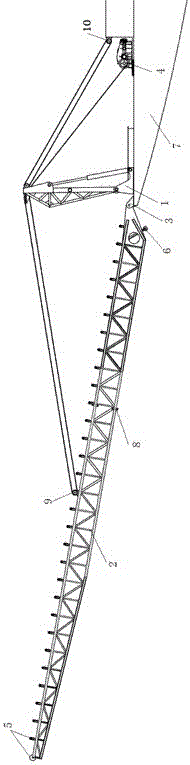

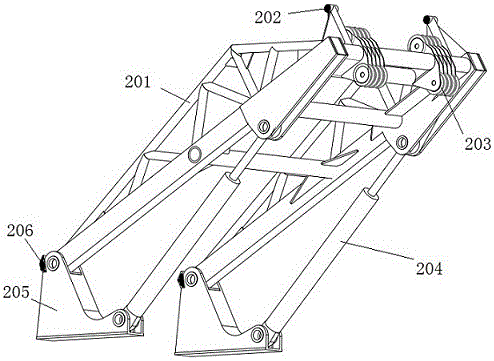

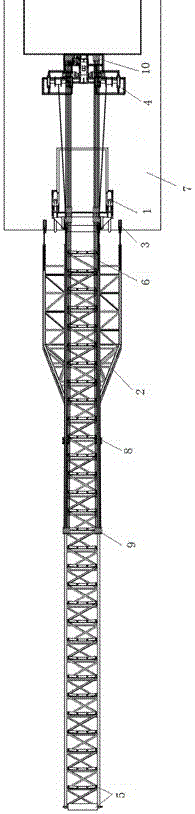

[0012] attached figure 1 Among them, the base of the gantry system (1) is welded on the deck of the hull (7), the conveying arm (2) is hinged to the arm support (3) on the hull (7), and the double-barrel hoist (4) is installed on the gantry Immediately behind the frame system (1), the conveying arm frame (2) is equipped with idler rollers (5), the upper and lower cross bars of the arm frame are equipped with upper carrying idler rollers and lower return idler rollers, and there are reversing head rollers at the front end. The device (6) is arranged inside the large end of the conveying arm frame (2). The double-drum hoist (4) drives the steel wire rope through the top pulley block of the gantry system (1), and connects to the pulley block on the conveying arm (2) to realize the lifting of the conveying arm (2). Another group of pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com