Phase change heat storage material with multiple phase change points and preparation technology thereof

A technology of phase change heat storage and phase change materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of single phase change heat storage temperature, low heat storage density, single phase change temperature of phase change materials, etc. , to achieve effective use of energy and improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

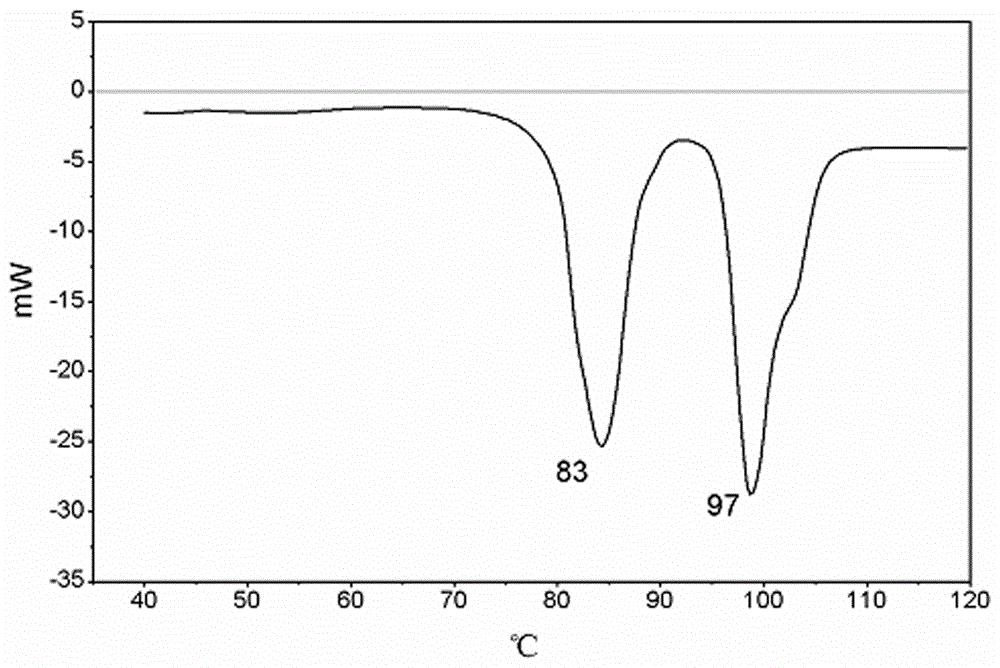

[0025] A phase-change heat storage material with multiple phase-change points is prepared using the following quality material-level steps: 120 g of erythritol, 80 g of trimethylolethane, and 10 g of nano-silicon dioxide. First, add 120g of erythritol into the reaction kettle through the feeding port, heat it at 140°C to completely melt and then stir, then slowly add 80g of trimethylolethane into the reaction kettle, and after it is fully melted, slowly add 10g of nano Silica, stirred for 1 hour and removed for DSC testing.

[0026] Using a differential calorimetry scanner (DSC) to test its phase transition temperature, it is obtained as figure 1 The phase change material with two phase change temperature points, the peak temperatures of the two phase change temperature points are 83°C and 97°C respectively, can be effectively applied to thermal storage solar water heating system.

Embodiment 2

[0028] A phase change heat storage material with multiple phase transition points is prepared using the following high-quality material-level steps: 140 g of erythritol, 60 g of trimethylolpropane, and 10 g of nano-titanium dioxide. First, add 140g of erythritol into the reaction kettle through the feeding port, heat it at 140°C to completely melt and then stir, then slowly add 60g of trimethylolethane into the reaction kettle, and after it is fully melted, slowly add 10g of nano Titanium dioxide, stirred for 1 hour and taken out for DSC test.

Embodiment 3

[0030] A phase change thermal storage material with multiple phase transition points is prepared using the following quality material-level steps: 120 g of xylitol, 80 g of 2-amino-2-methyl-1,3-propanediol, and 10 g of nano-copper. First, add 120g of erythritol into the reaction kettle through the feeding port, heat it at 140°C to completely melt and then stir, then slowly add 80g of trimethylolethane into the reaction kettle, and after it is fully melted, slowly add 10g of nano Copper, removed for DSC test after stirring for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com