A heat treatment method for nuclear island super large cross-section forgings

A heat treatment method and super technology, applied in the field of heat treatment, can solve the problem of inability to measure the heat treatment process on-line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

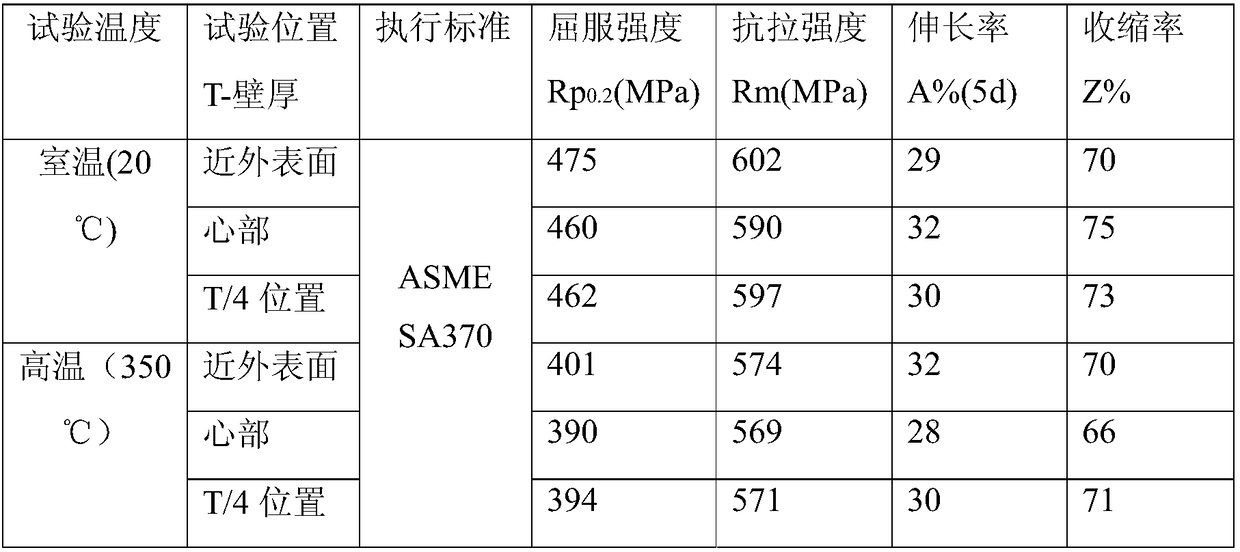

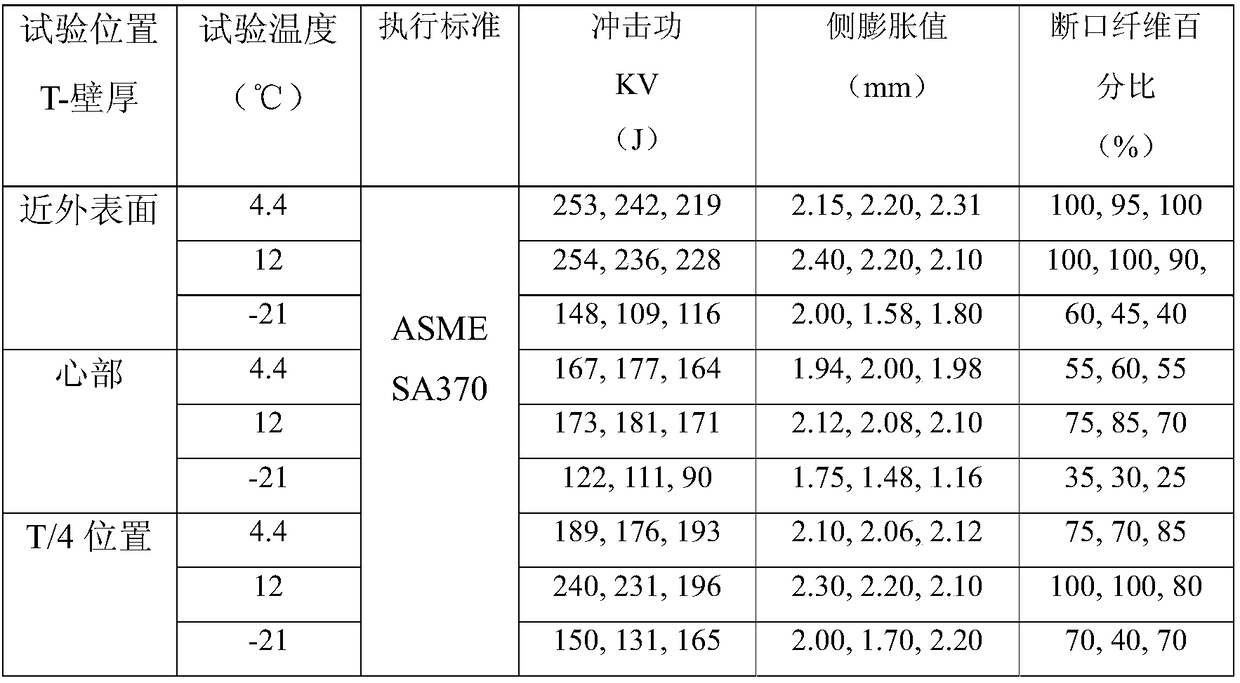

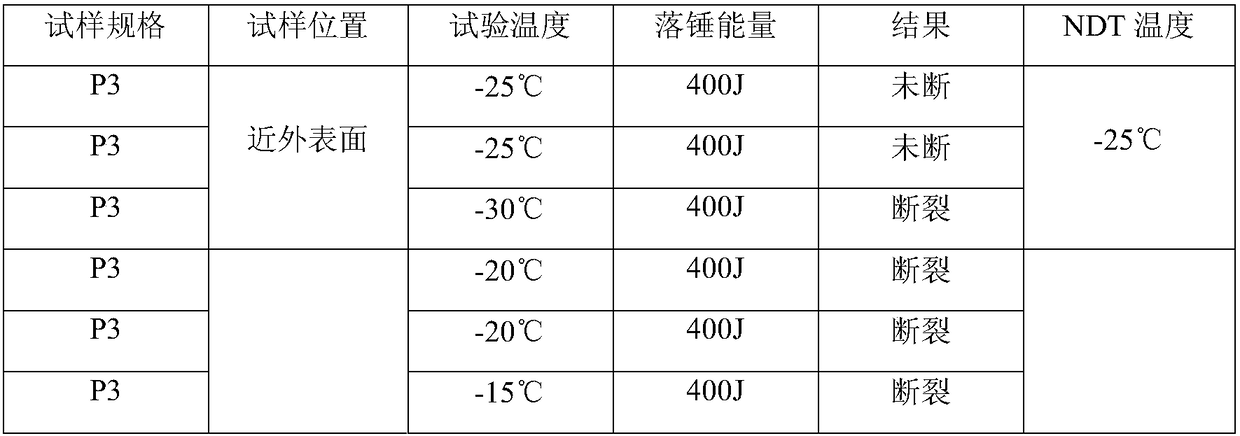

Examples

Embodiment 1

[0023] The present embodiment provides a heat treatment method for a nuclear island super-large cross-section forging (material is SA508Gr3), which includes the following steps:

[0024] (a) Rough machining: process the inner and outer surfaces of the maximum wall thickness of the super-large cross-section forging of the core island to the delivery size, leaving a margin of 10-15 mm on one side; if there is a step, the chamfer should be greater than R15; Place thermocouples on the inner and outer surfaces of the largest and smallest wall thicknesses of island super-large cross-section forgings (the thermocouples are placed in the metal compact and connected to the forging by welding, and the temperature deviation between the thermocouples during the subsequent heat treatment and heat preservation process does not exceed ±10 ℃).

[0025](b) Preliminary heat treatment: Place the large opening of the nuclear island super-large cross-section forging in the middle of the heat treat...

Embodiment 2

[0039] This embodiment provides a heat treatment method for a nuclear island super-large cross-section forging (the material is SA508Gr3), the steps of which are basically the same as those in Embodiment 1, the difference is that the heating rate and the holding temperature in each step are inconsistent, specifically:

[0040] In step (b), the temperature is raised from room temperature based on the thermocouple in contact with the workpiece (the heating rate is 200°C / hour), and the temperature is kept at 400°C for 10h; then the temperature is raised to 600°C (the heating rate is 50°C / hour ), keep warm for 10h; then heat up to 890°C (heating rate is 55°C / hour), keep warm for 10h and then cool in water for 3h;

[0041] (c) Quenching and tempering treatment: Based on the thermocouple in contact with the forging, start to heat up from room temperature (heating rate is 150°C / hour), keep at 400°C for 10 hours; then heat up to 600°C (heating rate is 50°C / hour hours), keep warm for 1...

Embodiment 3

[0055] This embodiment provides a heat treatment method for a nuclear island super-large cross-section forging (the material is SA508Gr3), the steps of which are basically the same as those in Embodiment 1, the difference is that the heating rate and the holding temperature in each step are inconsistent, specifically:

[0056] In step (b), the temperature is raised from room temperature based on the thermocouple in contact with the workpiece (the heating rate is 200°C / hour), and the temperature is kept at 500°C for 5h; then the temperature is raised to 700°C (the heating rate is 100°C / hour ), keep warm for 5h; then heat up to 900°C (heating rate is 50°C / hour), keep warm for 18h and then cool in water for 5h;

[0057] (c) Quenching and tempering treatment: Based on the thermocouple in contact with the forging, start to heat up from room temperature (heating rate is 200°C / hour), keep it at 500°C for 5 hours; then raise the temperature to 700°C (heating rate is 50°C / hour hours), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com