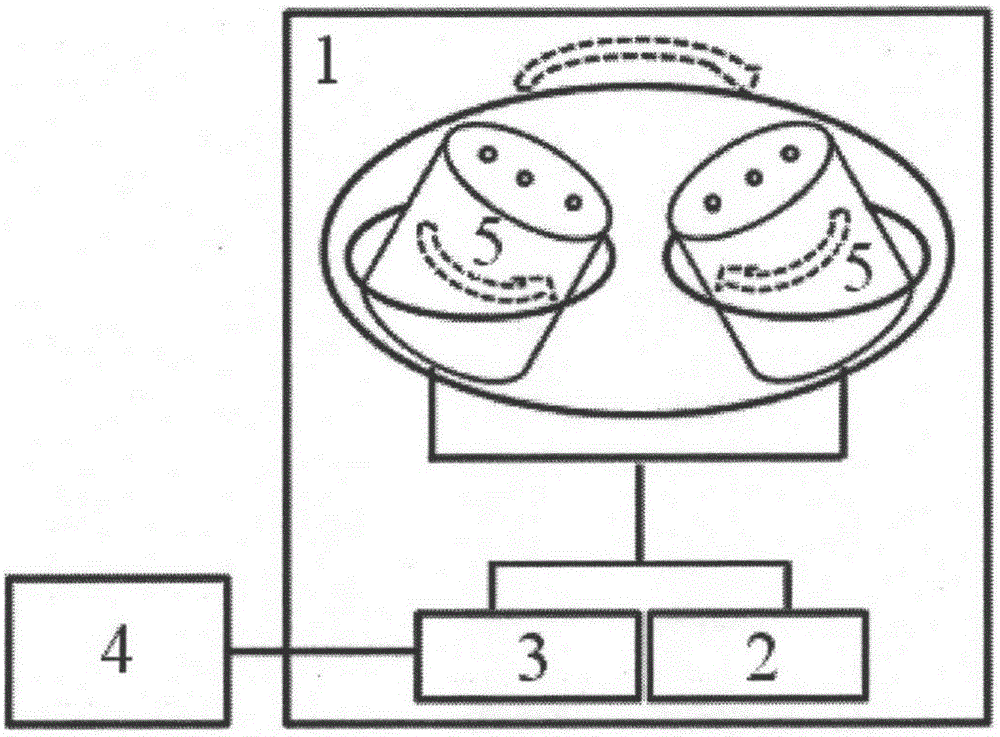

Equipment and method for non-contact dissolution and deaeration of high-concentration and high-viscosity spinning solution

A non-contact, spinning solution technology, applied in spinning solution preparation, spinning solution filtration, filament forming treatment, etc., can solve the problem of easy pollution of the system, damage of raw materials, low degassing efficiency of the degassing process, etc. problems, to avoid oil pollution, reduce damage, and improve defoaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Cellulose and 1-ethyl-3-methylimidazole acetate / dimethyl sulfoxide composite solvent (1-ethyl-3-methylimidazole acetate: the mass ratio of dimethyl sulfoxide is 3 : 7) directly add in two material cups 5 of 316 stainless steel by mass ratio 25: 100, turn on the temperature control device 3, set the temperature at 110°C, start the gear transmission 1, set the revolution speed to 2000rpm, and the rotation speed to 1800rpm, make the material cup 5 revolve and rotate, and obtain the spinning solution after dissolving for 5 minutes; open the pressure control device 2, set the vacuum degree to -0.097MPa, set the temperature of the temperature control device 3 to 80°C, and adjust the material cup The revolution speed of 5 is 1500rpm, the rotation speed is 1300rpm, and a transparent and clear spinning solution is obtained after degassing for 5 minutes.

Embodiment 2

[0025] Add polyacrylonitrile and DMSO directly into two HDPE plastic material cups 5 at a mass ratio of 23:100, turn on the temperature control device 3, set the temperature to 80°C, start the gear transmission device 1, and set the revolution speed to 1850rpm , the rotation speed is 1600rpm, make the material cup 5 revolve and rotate, and obtain the spinning solution after dissolving for 10 minutes; open the pressure control device 2, set the vacuum degree to -0.095MPa, and set the temperature of the temperature control device 3 to 60°C, The revolution speed of the material cup 5 was adjusted to 1650 rpm, the rotation speed was 1400 rpm, and a transparent and clear spinning solution was obtained after degassing for 3 minutes.

Embodiment 3

[0027] Add aramid fiber and concentrated sulfuric acid directly into two 316 stainless steel material cups 5 at a mass ratio of 21:100, turn on the temperature control device 3, set the temperature to 90°C, start the gear transmission device 1, and set the revolution speed to 1000rpm , the rotation speed is 800rpm, so that the material cup 5 is revolutionized and rotated, and the spinning solution is obtained after dissolving for 15min; the pressure control device 2 is opened, the vacuum degree is set at -0.097MPa, the revolution speed of the adjustment material cup 5 is 1000rpm, and the rotation speed at 900rpm, a transparent and clear spinning solution was obtained after degassing for 8 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com