Large-dynamic range high-precision optical axis measurement device

A large dynamic range, measuring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as improving detection accuracy, and achieve the effect of improving detection accuracy and broadening detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

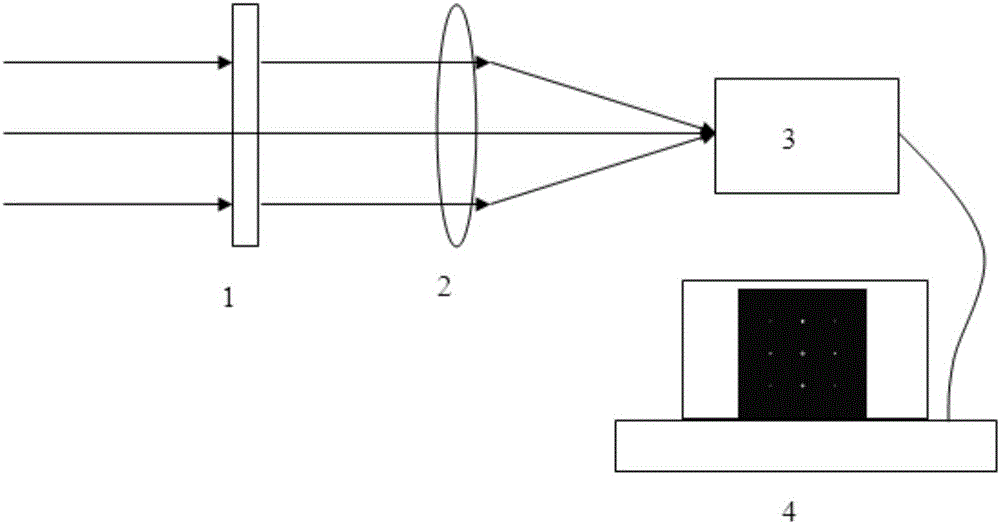

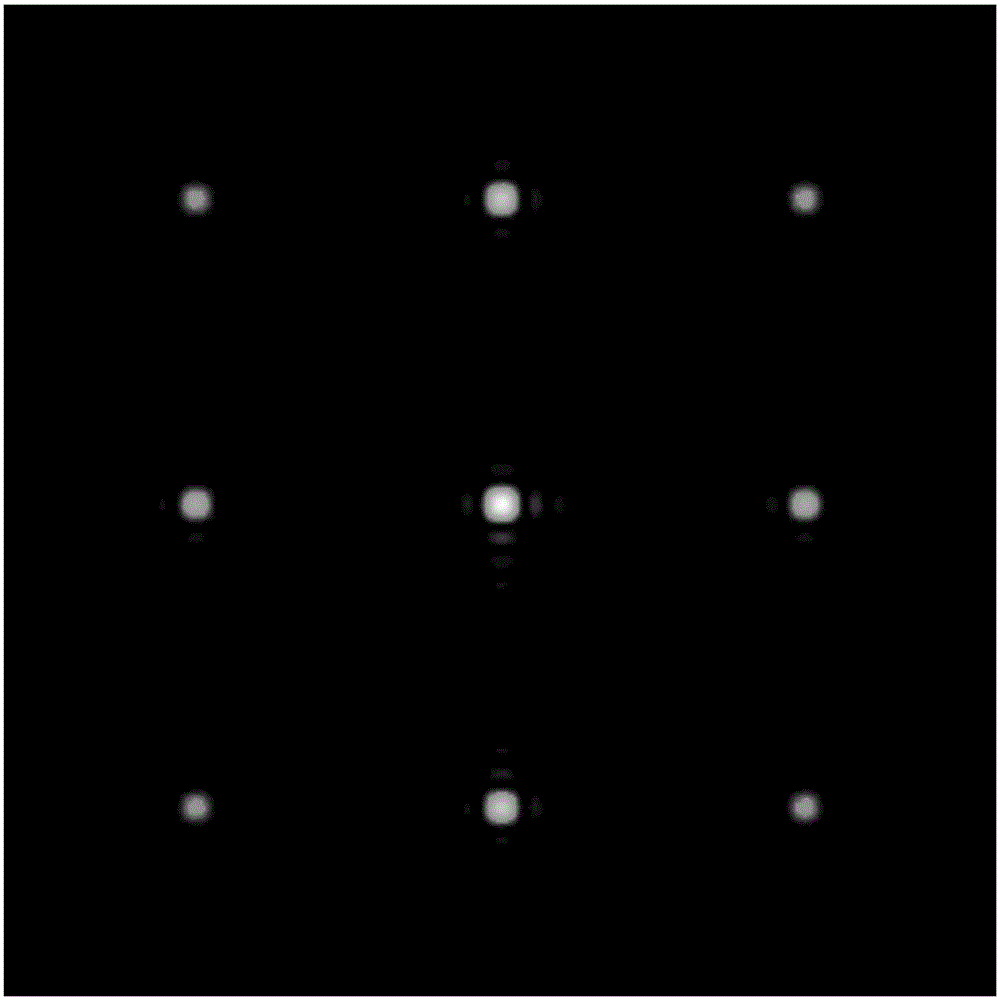

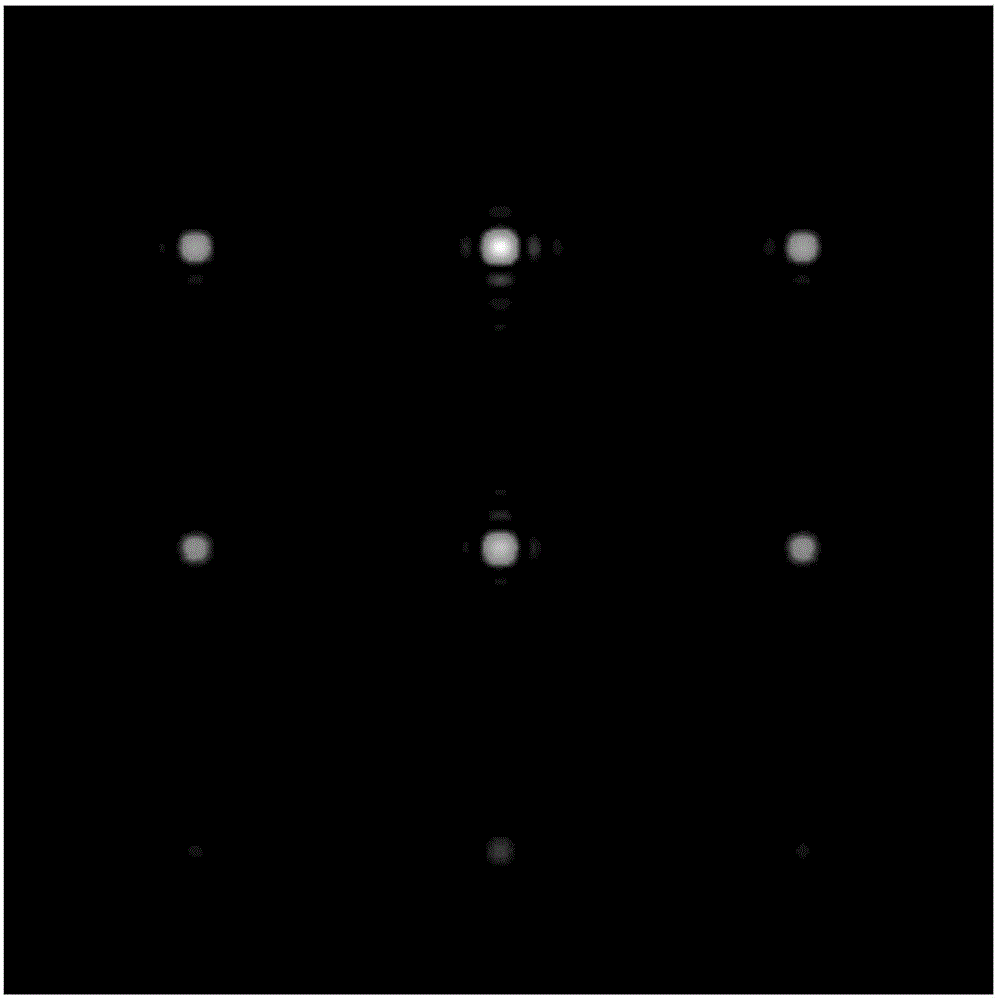

[0018] Such as figure 1 As shown, the present invention includes: a high-precision optical axis measurement device with a large dynamic range, which is composed of a two-dimensional spectroscopic module 1, an imaging module 2, a far-field recording module 3 and a far-field centroid calculation module 4, wherein the far-field recording module 3 includes Imaging CCDs and image recording devices. The far-field recording module 1 collects the light spot array and saves it in the memory of the far-field centroid calculation module 4 . The far-field centroid calculation module 4 calculates the centers Cx and Cy of the entire spot array according to the centroid calculation formula, and uses the center point to select the calculation area of the central spot, and then obtains the surrounding 8 spots by translating the calculation area of the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com