Capacitance-type delayed oil level signal device

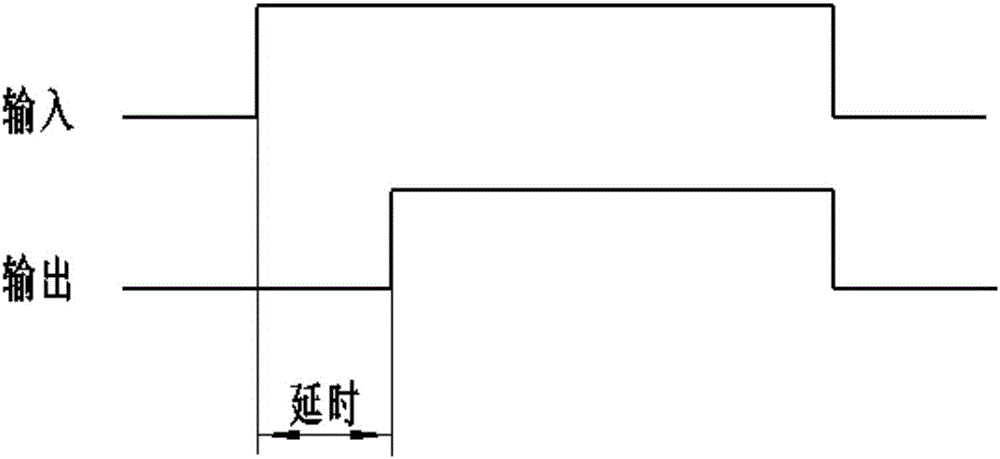

An oil level annunciator and capacitive technology, applied in the direction of buoy liquid level indicator, etc., can solve the problems of reliability dependence of liquid level alarm and high false alarm rate, and achieve the effect of eliminating dependence, eliminating false alarm and simplifying design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

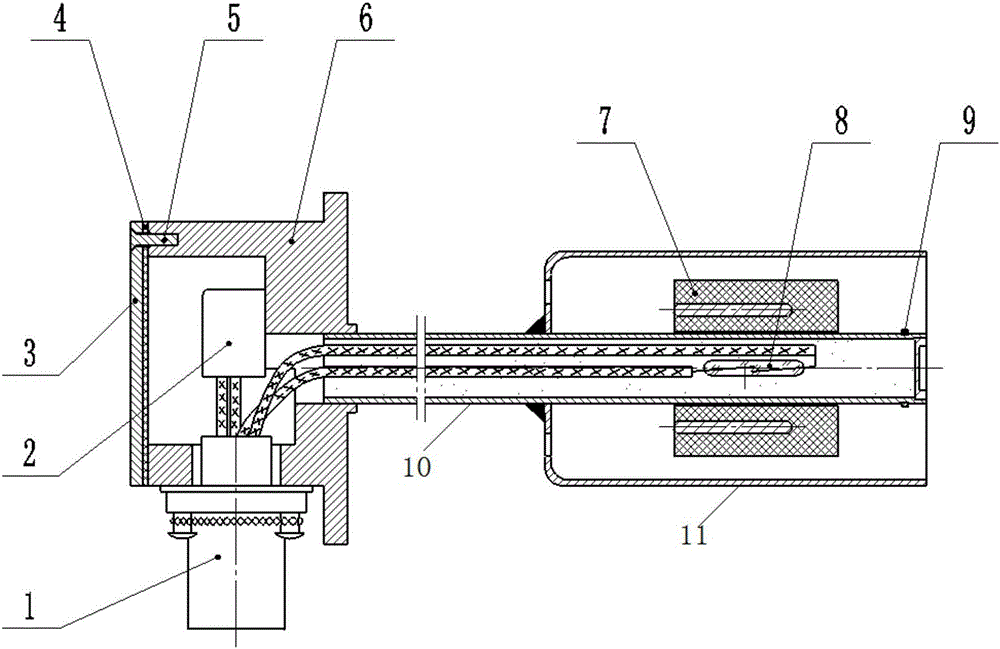

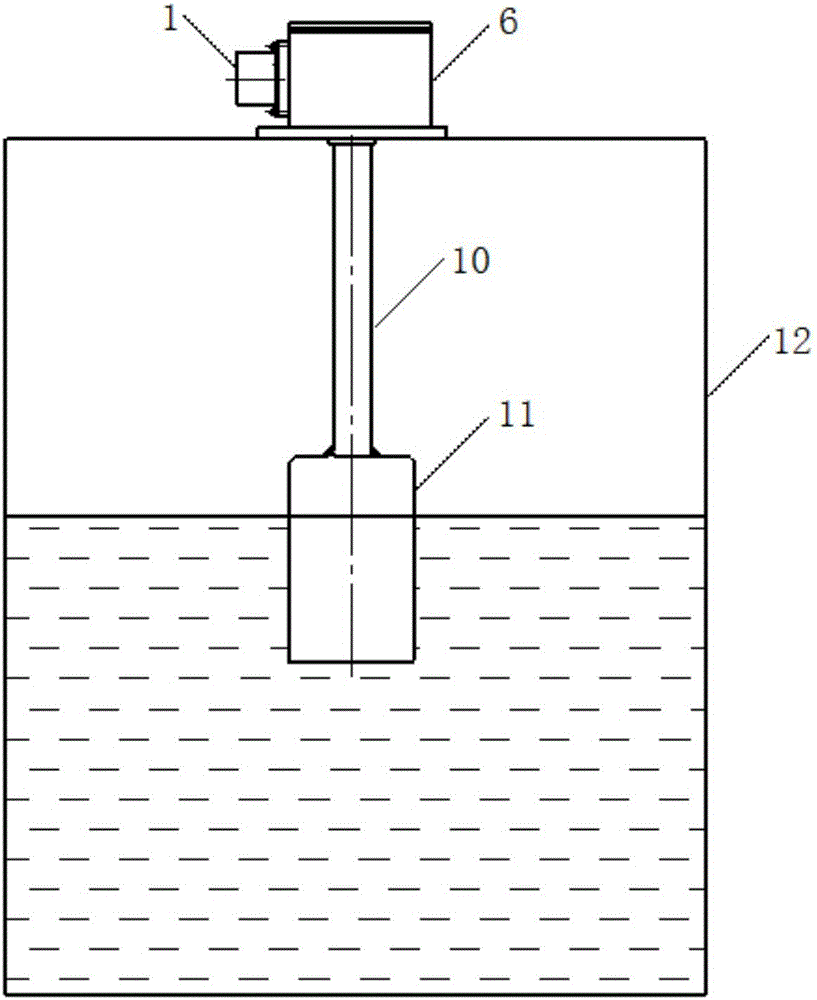

[0016] refer to figure 1 . In the embodiment described below, a capacitive time-delay oil level signaler includes an annunciator sensor and a junction box housing 6 with a socket 1, a time relay 2 arranged in the junction box housing 6, Among them, the socket 1 provides an electrical interface with the power supply and the signal receiving device, and the electrical interface connects the external power supply and the signal receiving device with the signal device. The retaining ring 9 arranged at the tail section of the guide rod 10 limits the movable range of the magnetic float assembly. The magnetic float assembly 7 is located at the lower end of the annunciator and follows the change of the liquid level. The reed switch 8 is potted in the guide rod 10 at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com