Method for making leadless edge connector plate

A manufacturing method and technology of finger boards, which are applied in the manufacture of printed circuits, the reinforcement of conductive patterns, the formation of electrical connections of printed components, etc., can solve the problems of easy etching of normal lines, affect product quality, poor removal effect, etc., and achieve short production cycle , improve the pass rate, and easily remove the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

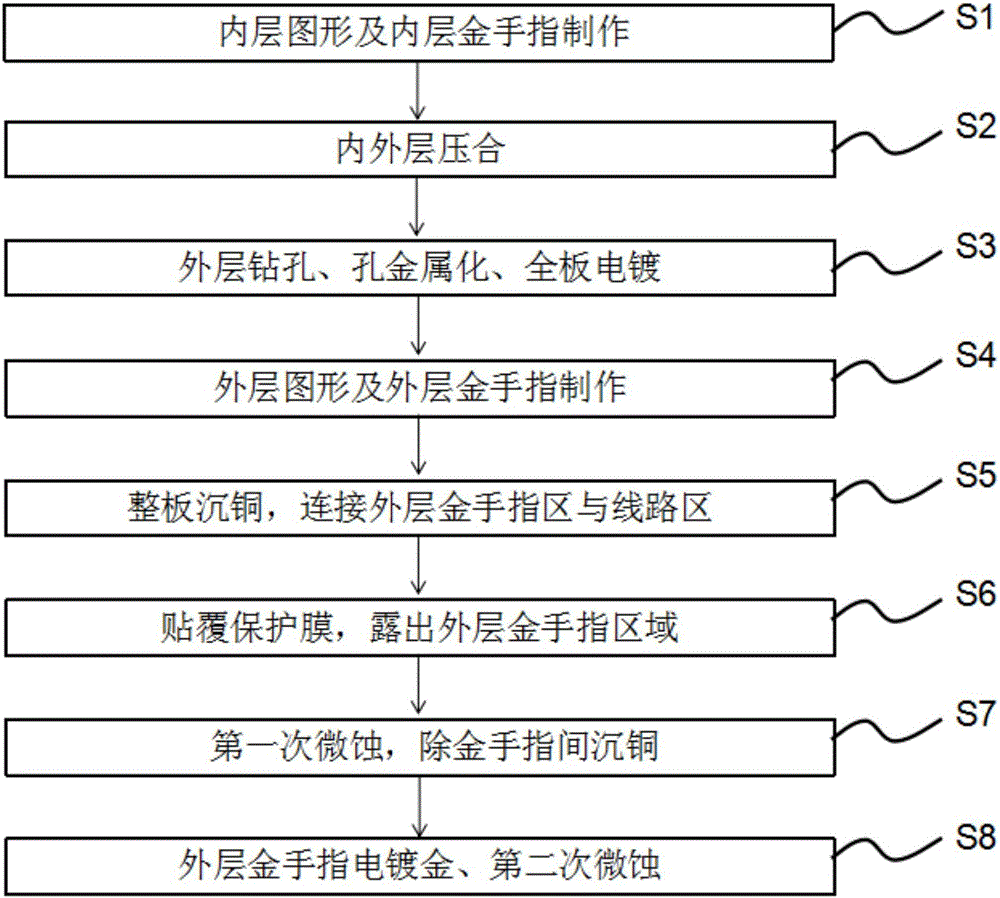

[0029] This embodiment provides a method for manufacturing a leadless gold finger board, which includes the following steps:

[0030] Pre-process: Cut a large sheet of incoming materials into plates of moderate size according to the design requirements of different plate numbers, remove the oxide film of oily substances on the surface of the plate by conventional methods, and perform chemical micro-etching to cause oxidation-reduction reactions on the copper surface. Roughen the copper surface.

[0031] S1, making the inner layer graphics, providing a cut and roughened inner layer core board, the inner layer core board has two positive and negative copper surfaces, and the front copper surface of the inner layer core board has an inner layer circuit area and Gold finger area of the inner layer; making film, after making the required circuit pattern on the film sheet, laminating the dry film on the surface of the inner core board, reacting the photosensitive film in the dry f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com