Fast-mellowing processing process of high-quality dark tea

A processing technology and technology for dark tea, applied in the field of rapid alcoholization processing technology, can solve problems such as reducing the production efficiency of enterprises, and achieve the effects of shortening processing time, improving taste and taste, and improving taste and alcohol.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

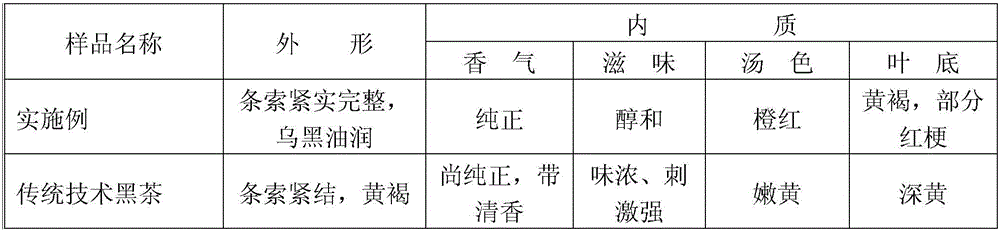

Examples

Embodiment

[0045] Pick one bud and three leaves (including part of one bud and four leaves) and the fresh tea leaves with the same tenderness. The fresh leaves are thinly spread at room temperature. The thickness of the spread leaves is 10cm and the spreading time is 4 hours; then use Drum-finish, high-temperature quick-fry, put fresh leaves in the pot at 260℃, the amount of leaves is 50kg / h, the fresh leaves are soft and sticky, the color turns dark green, dull, the grass smell is partially eliminated, the aroma is obvious, and even Consistent, the tender stems can be broken to complete the finalization; then use a cooling platform or a drying mat for cooling, the leaf thickness is 10cm, and the time is 30min; then the 55 type rolling machine is used for kneading, the kneading time is 25min, of which no pressure is 5min , Light pressure for 5 minutes, medium pressure for 10 minutes, and loose pressure for 5 minutes; the tea slabs after kneading are piled up immediately without delumping, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com