Method for producing soy sauce by using yeast autolysis fermentation

A technology of yeast autolysis and soy sauce, which is applied in the direction of food ingredients as color, food ingredients as taste improver, food ingredients as taste improver, etc. It can solve the problem that the flavor is not as good as the Japanese temperature control process, it is difficult to develop high-grade soy sauce, and protein utilization Low yield and other problems, to achieve the effect of improving the nutritional value of the product, prolonging the post-fermentation time, and improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Pretreatment of soy sauce stock solution: add sodium hydroxide solution to adjust the pH to 6.0, and keep warm at 45°C for 60min.

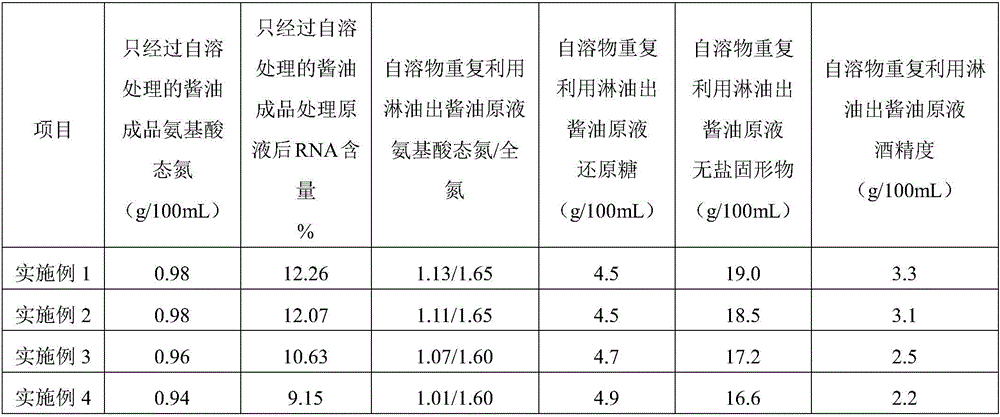

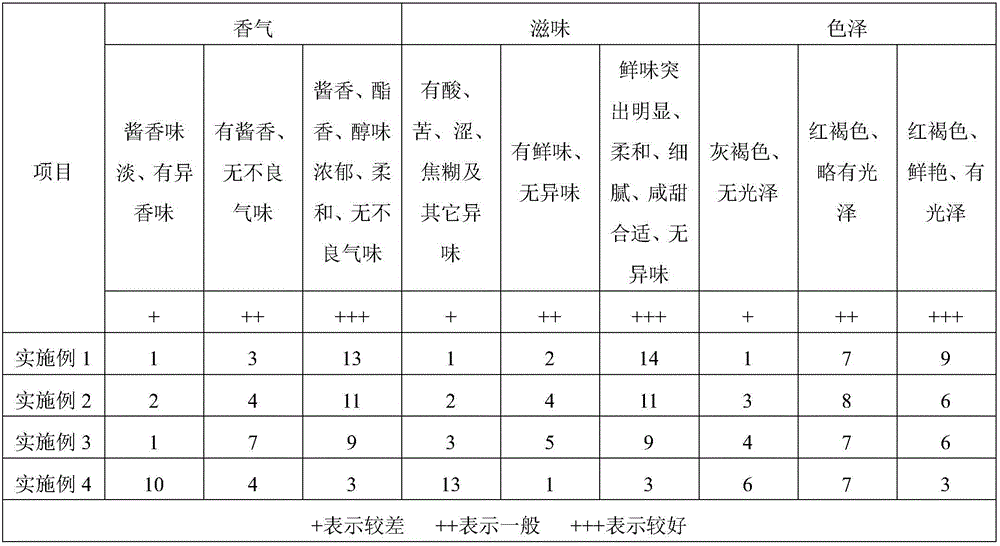

[0020] (2) Re-fermentation of autolyzed cell fragments: extract the upper 60% stock solution, and detect amino acid nitrogen and RNA content. Then heat at 95°C for 30 minutes, add 6‰ white sugar and 0.07‰ sucralose to prepare the finished product, and conduct sensory evaluation of the finished product; the lower 40% of the liquid is pumped back to the fermentation tank with a fermentation time of 3 months. The moromi continues to post-ferment for up to 180 days. During this process, the oil is poured every 15 days, and after the fermentation, the oil is poured to obtain the soy sauce stock solution. The oil-leached stock solution was tested for indicators, and the results are shown in Tables 1 and 2.

Embodiment 2

[0022] (1) Pretreatment of soy sauce stock solution: add sodium hydroxide solution to adjust the pH to 6.0, and keep warm at 40°C for 60 minutes;

[0023] (2) Re-fermentation of autolyzed cell fragments: extract the upper 60% stock solution, and detect amino acid nitrogen and RNA content. Then heat at 95°C for 30 minutes, add 6‰ white sugar and 0.07‰ sucralose to prepare the finished product, and conduct sensory evaluation of the finished product; the lower 40% of the liquid is pumped back to the fermentation tank with a fermentation time of 3 months. The moromi continues to post-ferment for up to 180 days. During this process, the oil is poured every 15 days, and after the fermentation, the oil is poured to obtain the soy sauce stock solution. The oil-leached stock solution was tested for indicators, and the results are shown in Tables 1 and 2.

Embodiment 3

[0025] (1) Pretreatment of soy sauce stock solution: add sodium hydroxide solution to adjust the pH to 6.5, and keep warm at 50°C for 40 minutes;

[0026] (2) Re-fermentation of autolyzed cell fragments: extract the upper 60% stock solution, and detect amino acid nitrogen and RNA content. Then heat at 90°C for 30 minutes, add 6‰ white sugar and 0.07‰ sucralose to prepare the finished product, and conduct sensory evaluation of the finished product; 40% of the liquid in the lower part is pumped back to the fermenter with a fermentation time of 3 months. The moromi continues to post-ferment for up to 180 days. During this process, the oil is poured every 15 days, and after the fermentation, the oil is poured to obtain the soy sauce stock solution. The oil-leached stock solution was tested for indicators, and the results are shown in Tables 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com