Processing pulse microscopic control method of EDM digital pulse power supply

A technology of pulse power supply and control method, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., and can solve problems such as unavoidable carbon deposition, damage to workpieces and electrodes, and difficulty in achieving continuous and stable processing.

Active Publication Date: 2018-05-08

苏州电加工机床研究所有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the contrary, if affected by factors such as the uncertainty of the state of the gap and the quality of the chip removal effect, it is difficult to ensure that each discharge pulse applied to both ends of the gap can form an effective discharge. When the proportion of the effective discharge pulse is small to a certain extent, The discharge will be difficult to stabilize, and then carbon deposits will appear in the discharge gap. Over time, it will cause arcing, damage the workpiece and electrodes, and eventually cause the processing to fail.

Since the above two control modes do not detect a single pulse and do not have the function of micro-adaptive control, it is difficult to avoid the occurrence of carbon deposition and arc burning, especially in the processing of precision micro, deep and narrow grooves, etc. It is difficult to achieve continuous and stable processing , to obtain a better processing effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0052] Example: A micro-control method of machining pulse of EDM digital pulse power supply

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

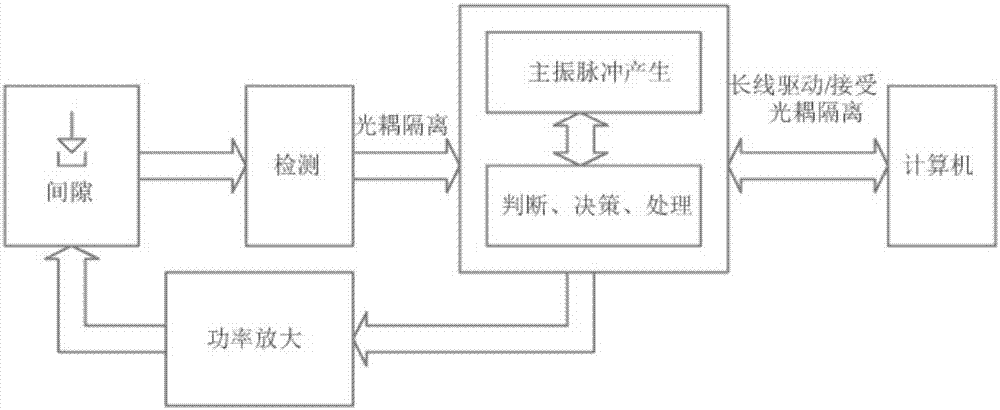

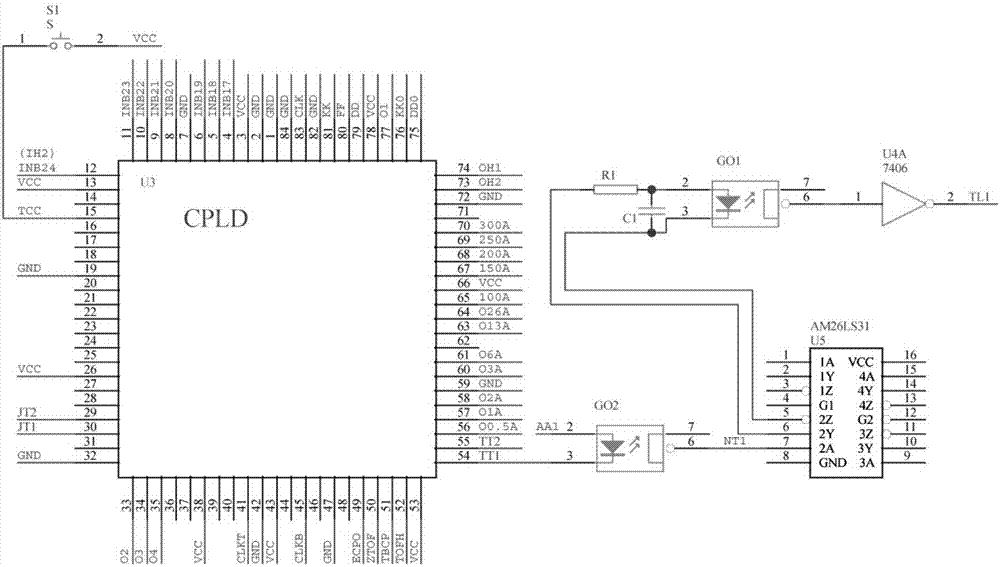

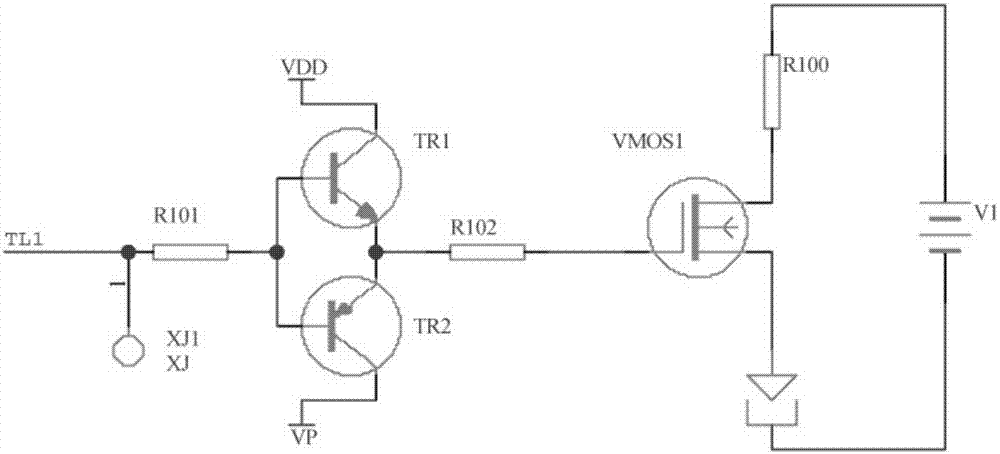

A micro control method of machining pulses of an electric spark digital pulse power supply is characterized by comprising the steps of: in the same discharge pause period, applying a first detection pulse with a lower pulse voltage amplitude value to a discharging gap at a fixed time and detecting the instantaneous voltage of the two ends of the discharging gap at a fixed time to initially judge whether the discharging gap state is good or bad; if the discharging gap state is bad, controlling the next machining pulse not to perform discharge machining; if the discharging gap state is good, applying a second detection pulse with a higher pulse voltage amplitude value to the discharging gap at a fixed time and detecting the instantaneous current of a discharge circuit, in which the discharging gap is, at a fixed time to finally judge whether the discharging gap state is good or bad; if the discharging gap state is bad, controlling the next machining pulse not to perform discharge machining; and if the discharging gap state is good, controlling the next machining pulse to perform discharge machining. Machining efficiency, surface roughness and electrode loss are in a contradiction system during electric spark machining, and the micro control method of the machining pulses of the electric spark digital pulse power supply, provided by the invention, can optimize the relationship among the machining efficiency, the surface roughness and the electrode loss through real-time detection and micro control according to actual requirements, so that dynamic balance of the machining efficiency, the surface roughness and the electrode loss can be realized.

Description

Technical field [0001] The invention relates to the technical field of electric spark machining, in particular to a machining pulse microscopic control method of an electric spark digital pulse power supply. This method uses the intermittent discharge to detect each discharge pulse in real time during the EDM process, and automatically controls the processing pulse output of the EDM digital pulse power supply according to the discharge state judged by the detection, so as to achieve efficient, stable and continuous Processing effect. The invention is suitable for wire cutting processing, forming processing and small hole processing in EDM. Background technique [0002] Electric discharge machining is a special machining method that uses the electric erosion effect generated by the pulse discharge between the electrode and the workpiece to remove the workpiece material. It is also called electric discharge machining or electro-erosion machining, and its English abbreviation is ED...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23H1/02

CPCB23H1/02

Inventor 吴强万符荣卢智良倪敏敏顾洪良叶新军许擎宇

Owner 苏州电加工机床研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com