Method for recycling lithium ferrous phosphate material from waste lithium ferrous phosphate battery positive plates

A lithium ferrous phosphate and battery cathode technology, which is applied in the field of recycling lithium ferrous phosphate materials from waste lithium ferrous phosphate battery cathode sheets, can solve the problem that the product consistency is difficult to guarantee, cannot meet the change of lithium ferrous phosphate, and the quality of raw materials Large and other problems, to achieve the effect of low cost, easy operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

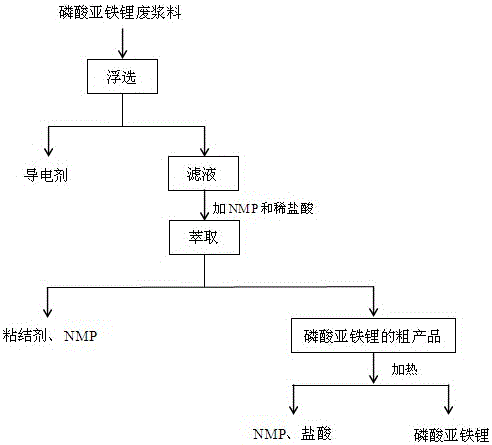

[0025] like figure 1 Shown, a kind of method that reclaims ferrous phosphate lithium material from waste lithium ferrous phosphate battery positive plate, comprises the steps:

[0026] 1. Pretreatment: roast the positive electrode sheet of the waste lithium ferrous phosphate battery at a temperature of 400°C for 4 hours, then pulverize it, sieve and recover the aluminum sheet of the positive electrode, and obtain the waste lithium iron phosphate slurry.

[0027] 2. Flotation: Treat the positive electrode waste slurry with deionized water, stir or ultrasonically oscillate at 100°C for 1 hour, remove the conductive agent by flotation, and obtain a mixture of lithium ferrous phosphate and binder.

[0028] 3. Extraction: Add the mixture of lithium ferrous phosphate and binder obtained above into the mixed solution of N-methylpyrrolidone and hydrochloric acid, and mix the mixture of lithium iron phosphate and binder with N-methylpyrrolidone and hydrochloric acid The mass ratio of ...

Embodiment 2

[0034] 1. Pretreatment: roast the positive electrode sheet of the waste lithium ferrous phosphate battery at a temperature of 300°C for 4 hours, then pulverize it, sieve and recover the aluminum sheet of the positive electrode, and obtain the waste lithium iron phosphate slurry.

[0035] 2. Flotation: Treat the positive electrode waste slurry with deionized water, stir or ultrasonically oscillate at 20°C for 3 hours, remove the conductive agent by flotation, and obtain a mixture of lithium ferrous phosphate and binder.

[0036] 3. Extraction: the mixture of lithium ferrous phosphate and binder obtained in step 1 is added to the mixed solution of N-methylpyrrolidone and hydrochloric acid, the mixture of lithium iron phosphate and binder is mixed with N-methylpyrrolidone and The mass ratio of the hydrochloric acid mixture is 10:7, the volume ratio of N-methylpyrrolidone to hydrochloric acid is 1:1, stirred or ultrasonically oscillated for 3 hours at room temperature, and rested f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com