Brinell hardness 450-level abrasion-resistant steel and manufacturing method thereof

A technology of Brinell hardness and manufacturing method, which is applied in the field of iron and steel manufacturing, can solve problems such as small tensile stress or stress value, cracking and deformation of steel plates, and poor welding performance, so as to improve service life, suppress cracking, and have good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

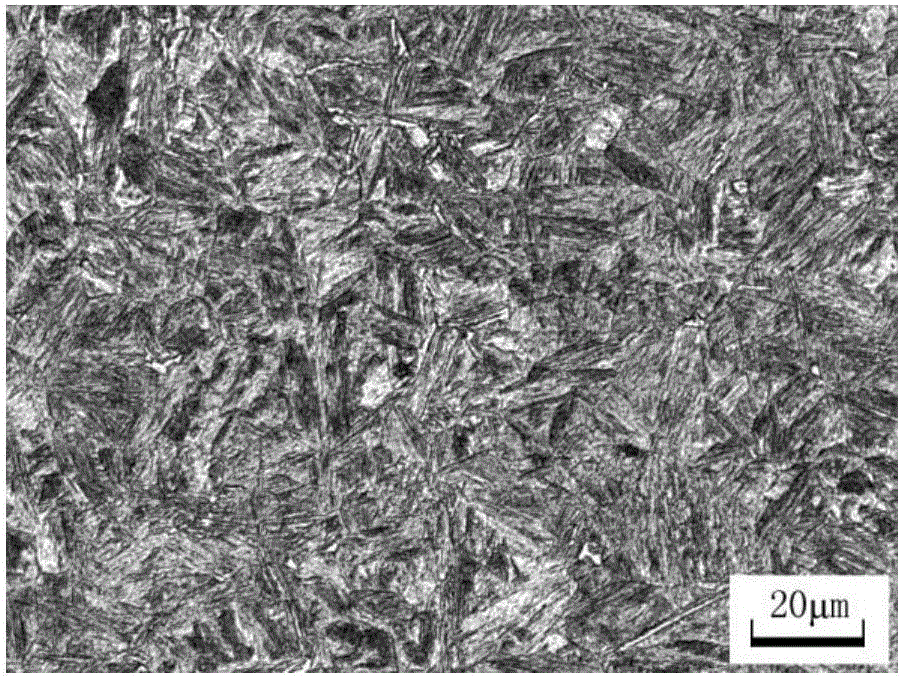

[0028] A Brinell hardness grade 450 wear-resistant steel with a thickness of 30mm, its chemical composition by weight percentage is: C0.20%, Si 0.51%, Mn 1.43%, P 0.007%, S 0.002%, Cr 0.70%, Ni 0.05 %, Mo0.026%, Als 0.031%, Ti 0.011%, V 0.008%, B 0.002%, and the rest are iron and inevitable impurities.

[0029] The following steps are carried out in sequence according to the proportioning chemical composition: smelting with ultra-pure steel process → molten iron desulfurization → converter top and bottom composite blowing → vacuum treatment → continuous casting into slab → slab heating → rolling → cooling → quenching → low temperature tempering → finished steel plate,

[0030] In the slab heating stage, the soaking temperature is 1250℃, the heating rate is 11min / cm, and the heating is 300min;

[0031] In the rolling step, rolling is performed at an opening temperature of 1060°C, a final rolling temperature of 1080°C, and a single-pass reduction ratio greater than 30% to roll ...

Embodiment 2

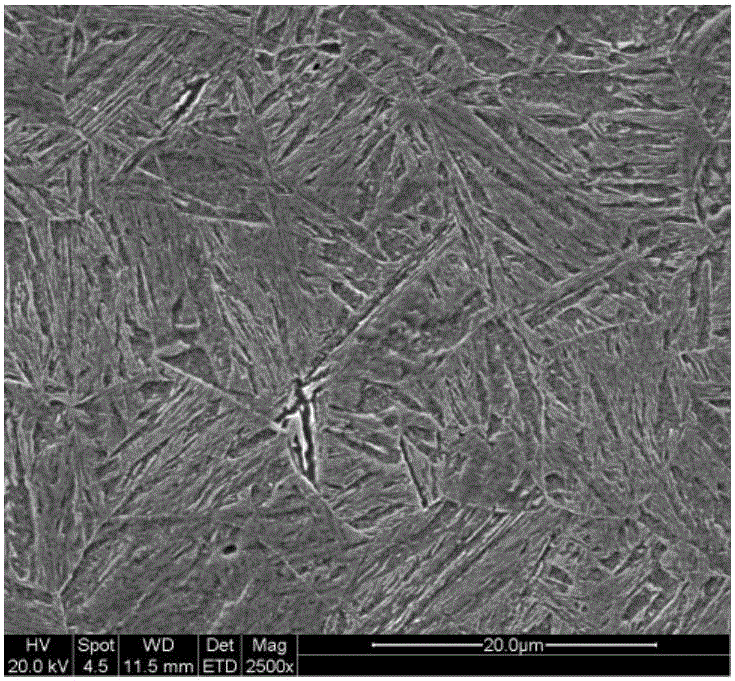

[0041] A Brinell hardness grade 450 wear-resistant steel with a thickness of 40mm, its chemical composition by weight percentage is: C0.19%, Si 0.44%, Mn 1.25%, P 0.01%, S 0.001%, Cr 0.68%, Ni 0.06 %, Mo 0.08%, Als 0.025%, Ti 0.001%, V 0.015%, B 0.002%, and the rest are iron and inevitable impurities.

[0042] The following steps are carried out in sequence according to the proportioning chemical composition: smelting with ultra-pure steel process → molten iron desulfurization → converter top and bottom composite blowing → vacuum treatment → continuous casting into slab → slab heating → rolling → cooling → quenching → low temperature tempering → finished steel plate,

[0043] In the slab heating stage, the soaking temperature is 1230℃, the heating rate is 10.5min / cm, and the heating is 400min;

[0044] In the rolling step, rolling is performed at an opening temperature of 1300°C, a final rolling temperature of 1010°C, and a single-pass reduction ratio greater than 40% to roll...

Embodiment 3

[0053] A Brinell hardness grade 450 wear-resistant steel with a thickness of 20mm, its chemical composition by weight percentage is: C0.17%, Si 0.58%, Mn 1.45%, P 0.003%, S 0.004%, Cr 0.85%, Ni 0.09 %, Mo 0.046%, Als 0.043%, Ti 0.0 1%, V 0.018%, B 0.003%, and the rest are iron and inevitable impurities.

[0054] The following steps are carried out in sequence according to the proportioning chemical composition: smelting with ultra-pure steel process → molten iron desulfurization → converter top and bottom composite blowing → vacuum treatment → continuous casting into slab → slab heating → rolling → cooling → quenching → low temperature tempering → finished steel plate,

[0055] Slab heating stage: the soaking temperature is 1190℃, the heating rate is 10.1min / cm, and the heating time is 220min;

[0056] In the rolling stage, the start rolling temperature is 1550℃, the final rolling temperature is 1100℃, and the single-pass reduction rate is greater than 22%;

[0057] The quen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com