Corn fiber ecological mask spunlaced material and preparation method thereof

A corn fiber, spunlace technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as environmental pollution, itchy facial mask skin, and unfavorable environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

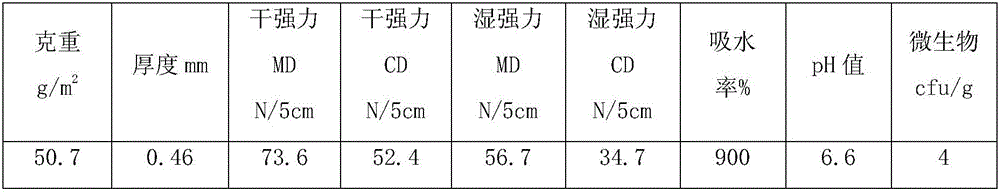

Image

Examples

Embodiment 1

[0021] The corn fiber ecological mask spunlace material of the present invention is made of 100% corn fiber, and the specification of the corn fiber is 12mm*1.6D.

[0022] The preparation method of corn fiber ecological mask spunlace material of the present invention comprises the following steps:

[0023] (1) Dissolving and thickening the corn fiber;

[0024] (2) sizing;

[0025] (3) Molding, spunlace;

[0026] (4) drying;

[0027] (5) Slitting.

[0028] In the above-mentioned step (1), the corn fiber concentration after thickening is 3%.

[0029] In the sizing process of the above-mentioned step (2), the headbox slurry is online at 10kg / min.

[0030] In the spunlace process of the above step (3), the mesh curtain speed is 100m / min, the suction vacuum is -7kpa, and the spunlace pressures of the 5 spunlace heads are 45bar, 70bar, 70bar, 100bar, and 100bar respectively.

[0031] The drying process of the above step (4) includes successively passing through the ovens whose...

Embodiment 2

[0033] The corn fiber ecological mask spunlace material of the present invention is made of 100% corn fiber, and the specification of the corn fiber is 12mm*1.6D.

[0034] The preparation method of corn fiber ecological mask spunlace material of the present invention comprises the following steps:

[0035] (1) Dissolving and thickening the corn fiber;

[0036] (2) sizing;

[0037] (3) Molding, spunlace;

[0038] (4) drying;

[0039] (5) Slitting.

[0040] In the above-mentioned step (1), the corn fiber concentration after thickening is 3%.

[0041] In the sizing process of the above-mentioned step (2), the headbox slurry is online at a rate of 15kg / min.

[0042] In the spunlace process of the above step (3), the mesh curtain speed is 101m / min, the suction vacuum is -7kpa, and the spunlace pressures of the 5 spunlace heads are 45bar, 70bar, 70bar, 100bar, and 100bar respectively.

[0043] The drying process of the above step (4) includes successively passing through the o...

Embodiment 3

[0045] The corn fiber ecological mask spunlace material of the present invention is made of 100% corn fiber, and the specification of the corn fiber is 12mm*1.6D.

[0046] The preparation method of corn fiber ecological mask spunlace material of the present invention comprises the following steps:

[0047] (1) Dissolving and thickening the corn fiber;

[0048] (2) sizing;

[0049] (3) Molding, spunlace;

[0050] (4) drying;

[0051] (5) Slitting.

[0052] In the above-mentioned step (1), the corn fiber concentration after thickening is 3%.

[0053] In the sizing process of the above-mentioned step (2), the headbox slurry is online at 12kg / min.

[0054] In the spunlace process of the above step (3), the mesh curtain speed is 100.5m / min, the suction vacuum is -7kpa, and the spunlace pressures of the 5 spunlace heads are 45bar, 70bar, 70bar, 100bar, and 100bar respectively.

[0055] The drying process of the above step (4) includes successively passing through the ovens who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com