Atmospheric pressure low-temperature plasma continuous treatment apparatus and method for fiber tows

A low-temperature plasma and tow fiber technology, which is applied in fiber processing, ultrasonic/sonic fiber processing, physical processing, etc., can solve the problems of intermittent work industry, hidden dangers in safety, and inability to complete processing online quickly. Reasonable structure design, avoid small deformation, low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further clarify the technical solution of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

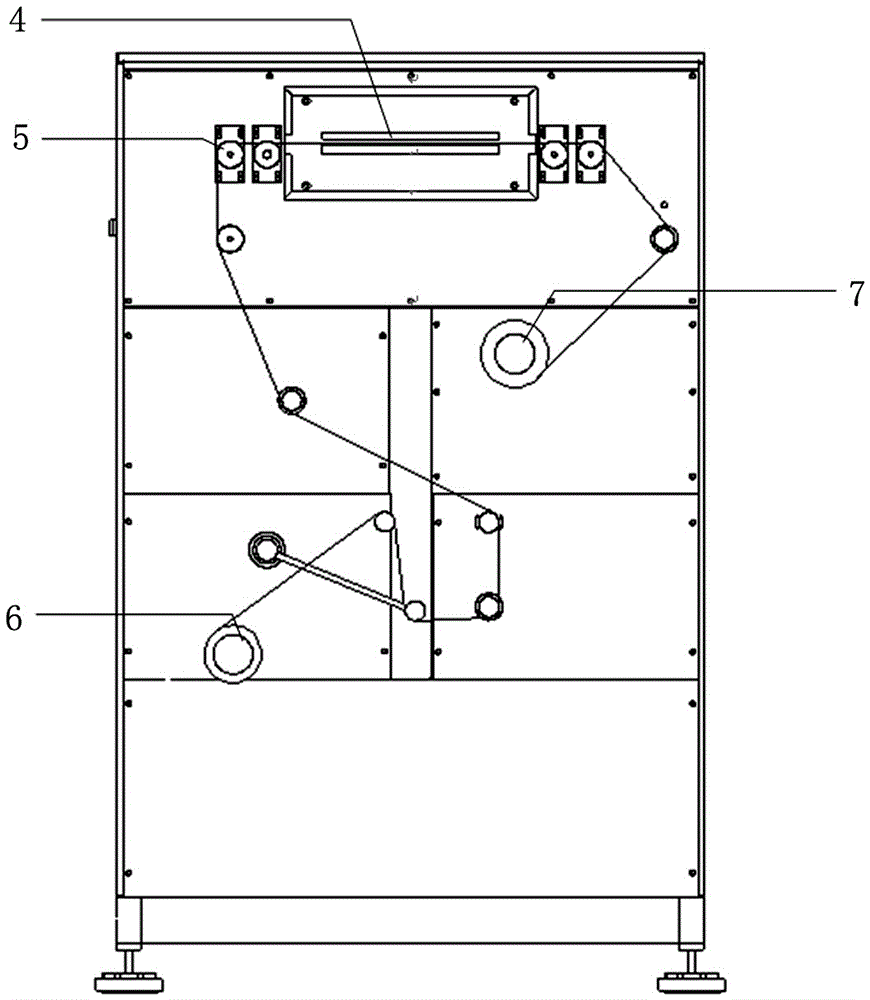

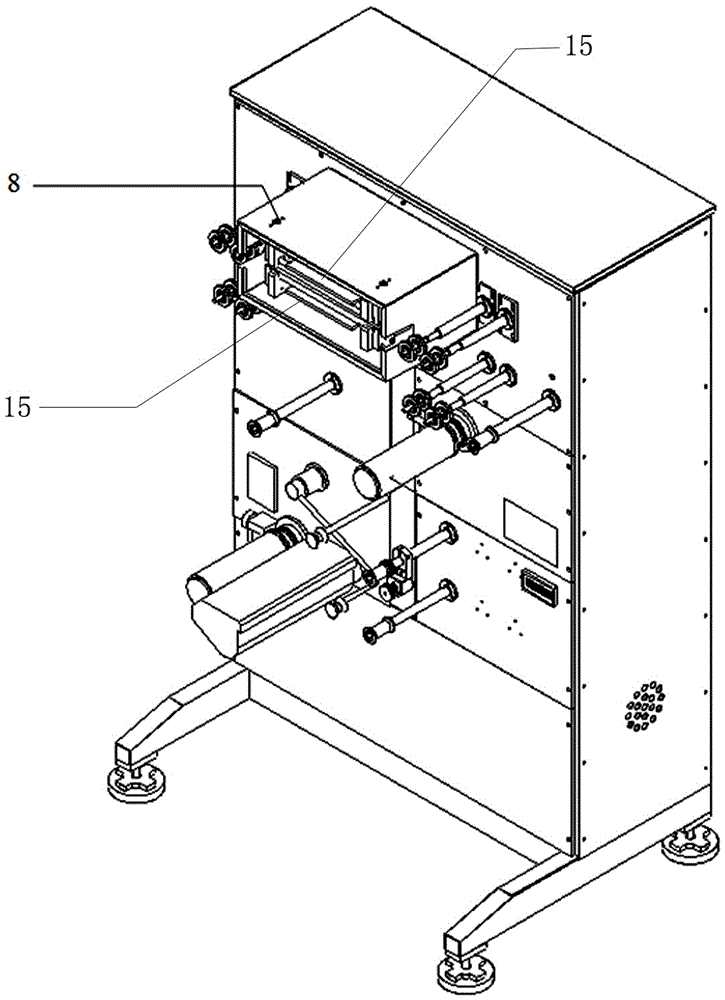

[0033] In the present embodiment, take the treatment of carbon fiber or polymer fiber bundle 3 as an example, such as Figure 1 to Figure 3 The shown is an atmospheric and normal pressure low temperature plasma continuous tow fiber processing equipment, including a box body, a low temperature plasma generating device, a feeding device 7, a retracting device 6, a tension adjustment mechanism, a guide wheel and other components.

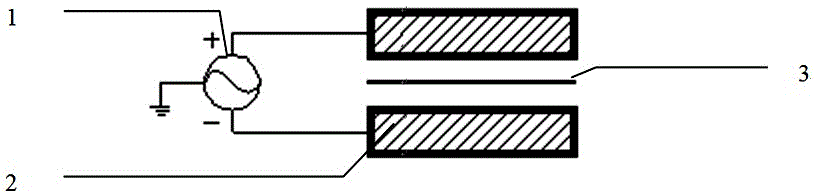

[0034] The low-temperature plasma generating device is a differential high-frequency high-voltage feeding dielectric barrier discharge plasma generating device, which is provided with a differential output high-frequency high-voltage power supply 1, and the low-temperature plasma generating device is provided with a wind collecting hood 14 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com