Paper plastic moulding method and paper plastic finished product thereof

A molding method and paper-plastic technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, paper, papermaking, etc., can solve problems such as poor product yield, bridging, and poor mass production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

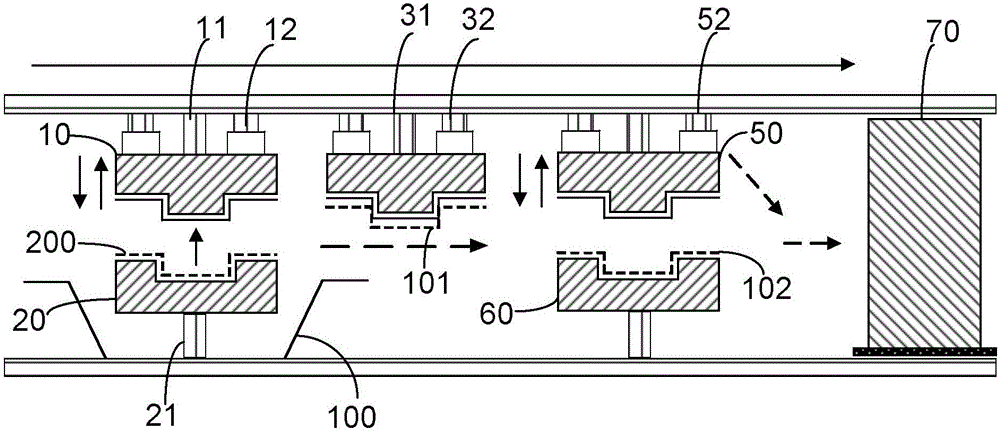

[0036] Relevant technical content and detailed description of the present invention, now cooperate accompanying drawing to explain as follows:

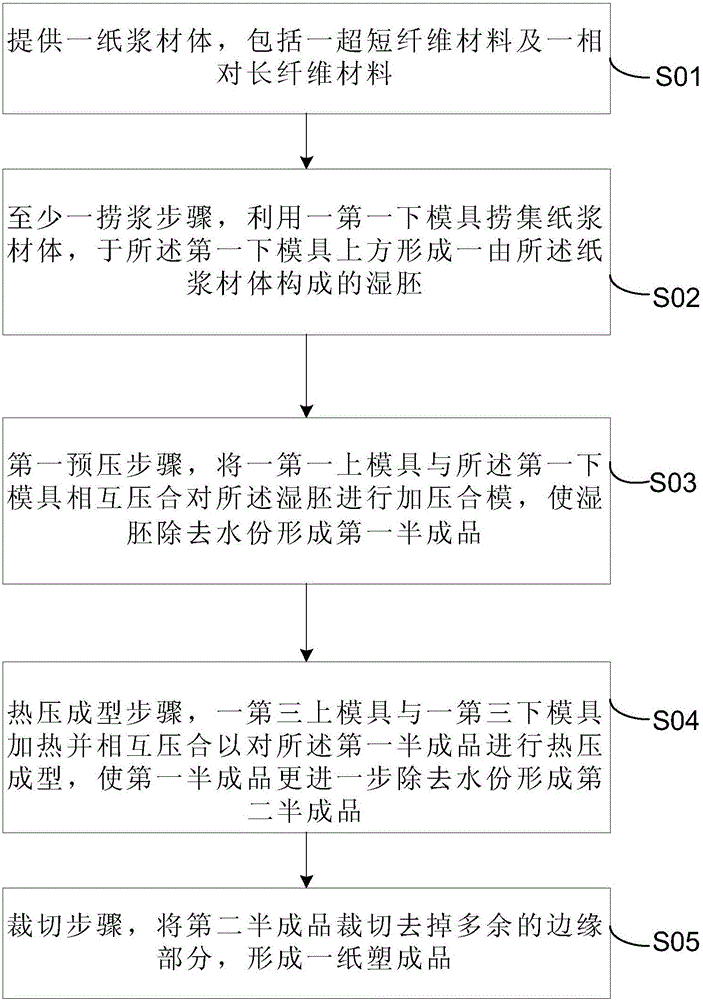

[0037] see figure 2 shown, where figure 2 It is a schematic flow chart of a paper molding method according to a preferred embodiment of the present invention. The present invention provides a kind of paper molding method, basically comprises the following steps:

[0038] S01: Provide a pulp material body, which has at least one fiber material, and the fiber material includes an ultra-short fiber material and a relatively long fiber material.

[0039]S02: Perform at least one pulp extraction step, including using a first lower mold to scoop up the pulp material body in a stock tank, and then form a wet base composed of the pulp material body above the first lower mold .

[0040] S03: Perform a first pre-pressing step, including pressing a first upper mold and the first lower mold to press and close the mold, and discharge part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com