A horizontally opposed air-cooled constant temperature engine

A horizontally opposed, air-cooled technology, applied to engine components, combustion engines, machines/engines, etc., can solve the problems of waste and high maintenance costs of cylinder blocks, and achieve smooth exhaust, avoid insufficient combustion, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

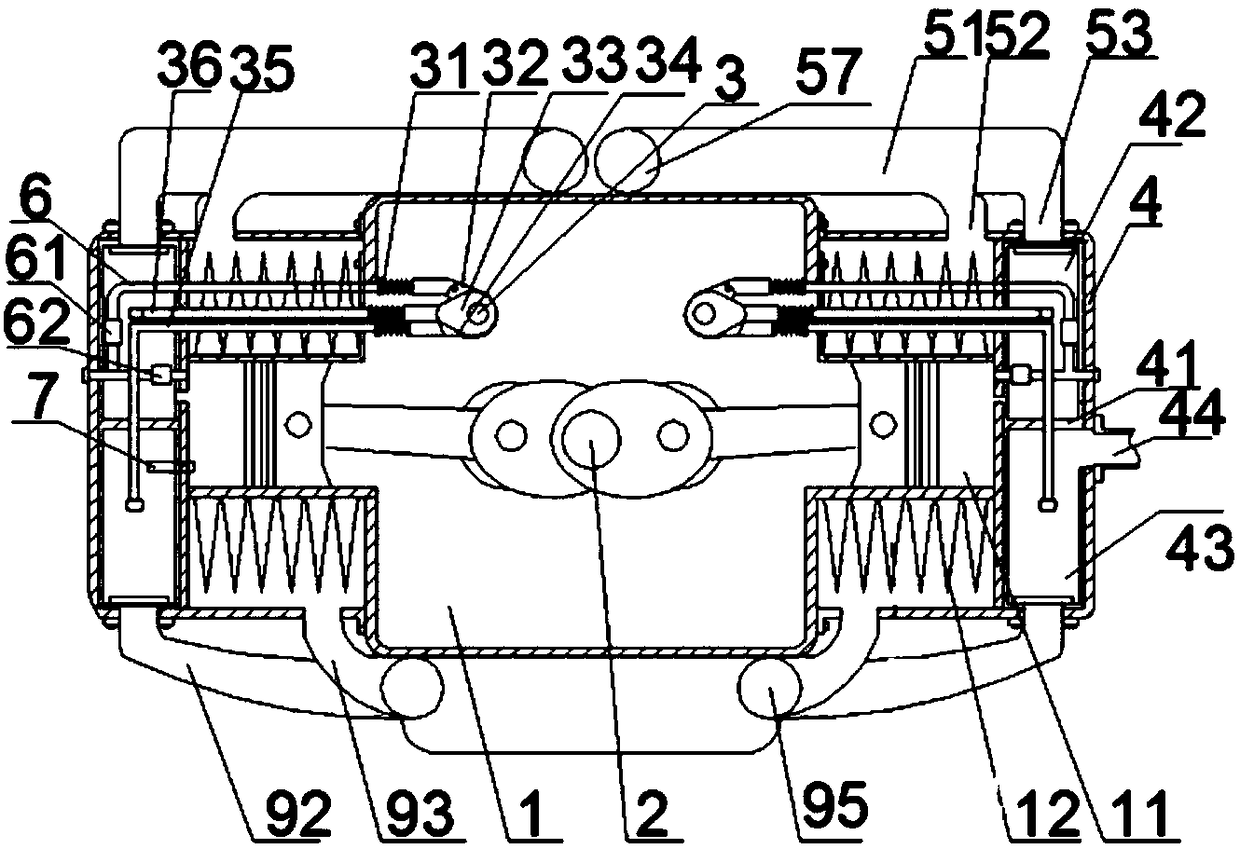

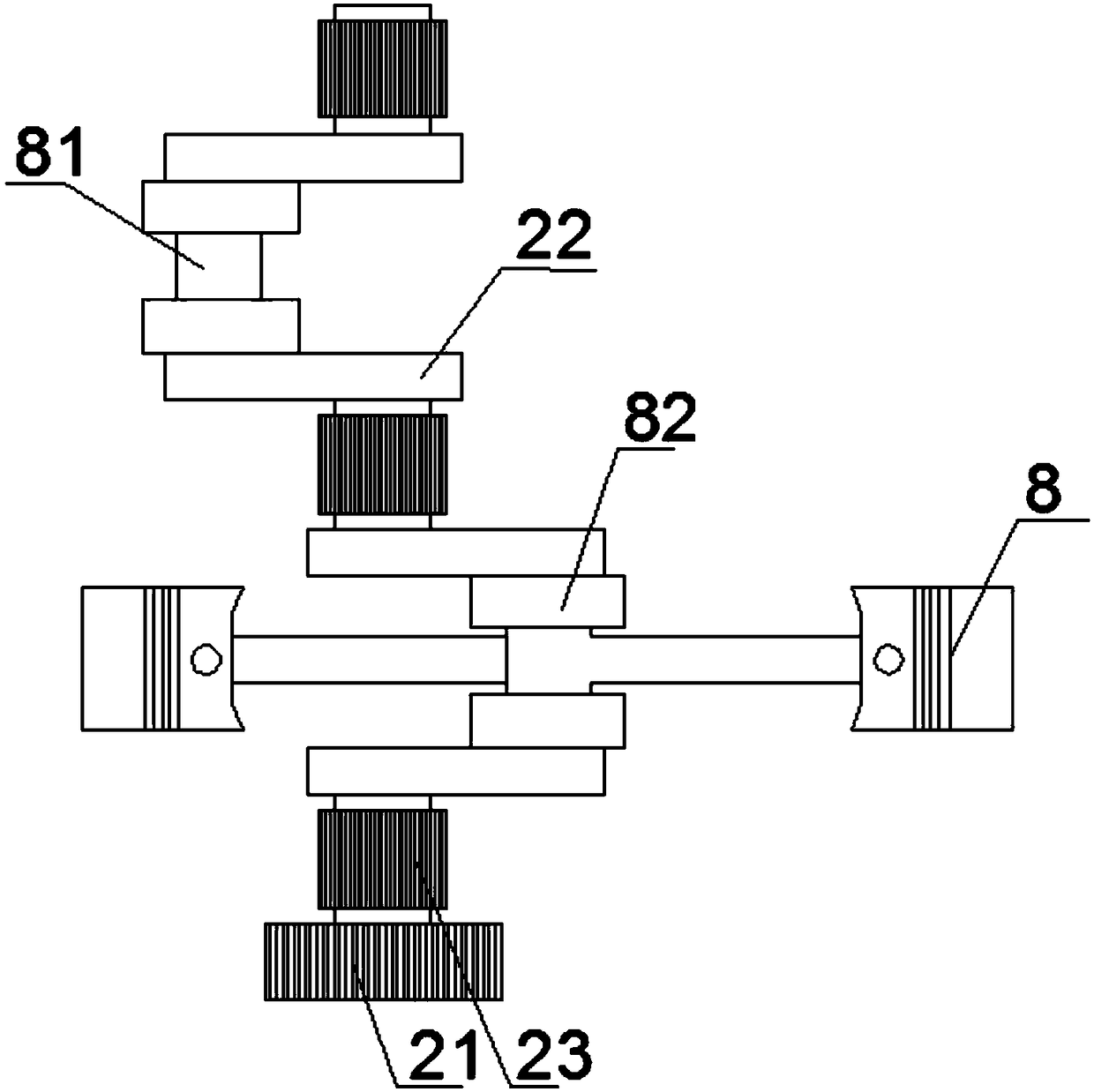

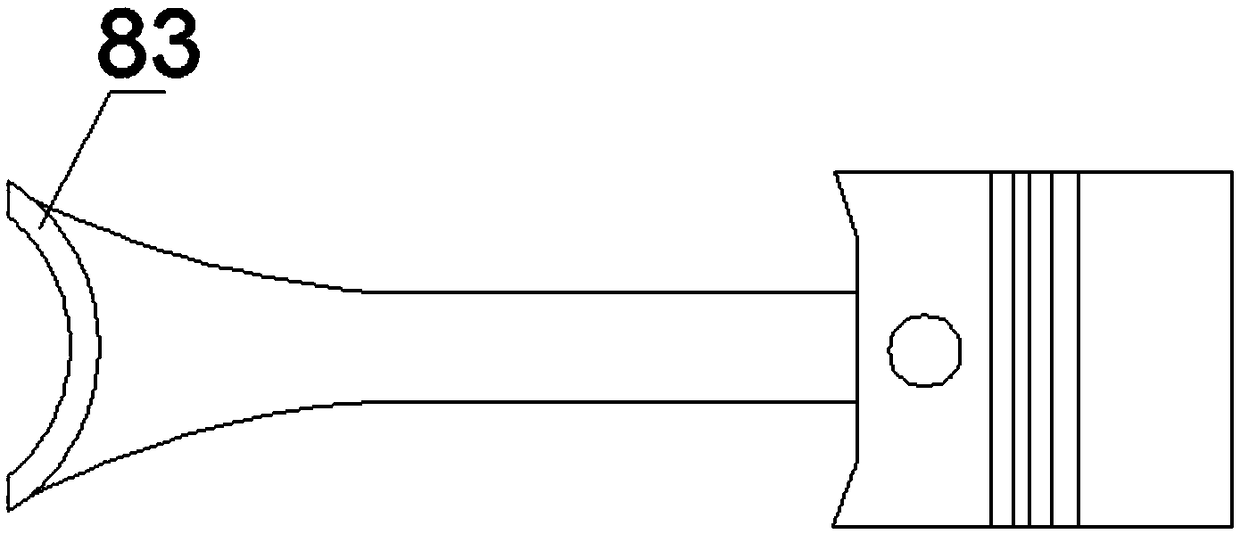

[0036]A horizontally opposed air-cooled constant temperature engine, comprising a crankshaft chamber 1, a crankshaft assembly 2, a camshaft 3, a cylinder head 4, an intake system 5, an oil inlet system 6, an ignition system 7, and a piston 8; the crankshaft chamber 1 Combustion chambers 11 are arranged at both ends, and a cooling chamber 12 is arranged on the outside of the combustion chamber 11. A cylinder head 4 is arranged at the outer ends of the combustion chamber 11 and the cooling chamber 12, and an intake cylinder 42 is arranged inside the cylinder head 4. And the exhaust cylinder 43, the exhaust valve 41 is arranged between the air intake cylinder 42 and the exhaust cylinder 43, the air intake cylinder 42 is connected with the intake system 5, and the exhaust cylinder 43 is connected with the exhaust system 9; A crankshaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com