Sensor layout method suitable for structure health monitoring and structure identification method

A technology of health monitoring and structural identification, applied in the testing of machines/structural components, instruments, measuring devices, etc., which can solve the problems of many types of sensors, poor durability, and structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

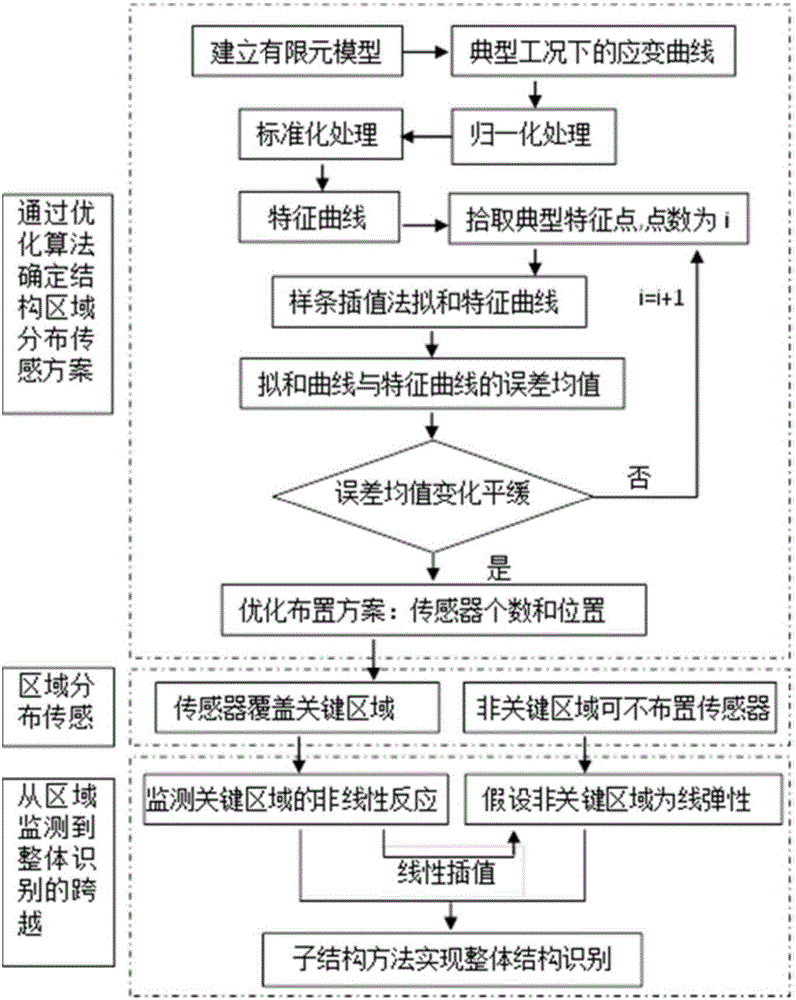

Method used

Image

Examples

Embodiment 1

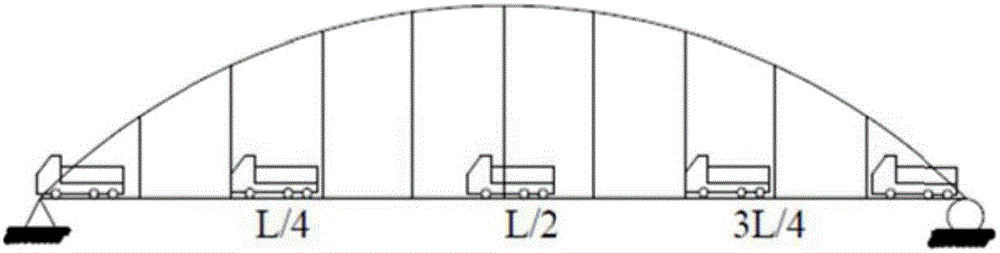

[0059] A tied arch bridge with a span of 64 meters, a height of 13 meters and a width of 14 meters, the finite element model of the 64 meters tied arch bridge, the length of the tie beam is 64 meters, so it can be divided into 64 units, each The unit length is 1 meter, so it can be determined that the gauge length of the pasted long gauge FBG sensor is 1 meter. This model is used to clearly explain the specific implementation steps of the present invention.

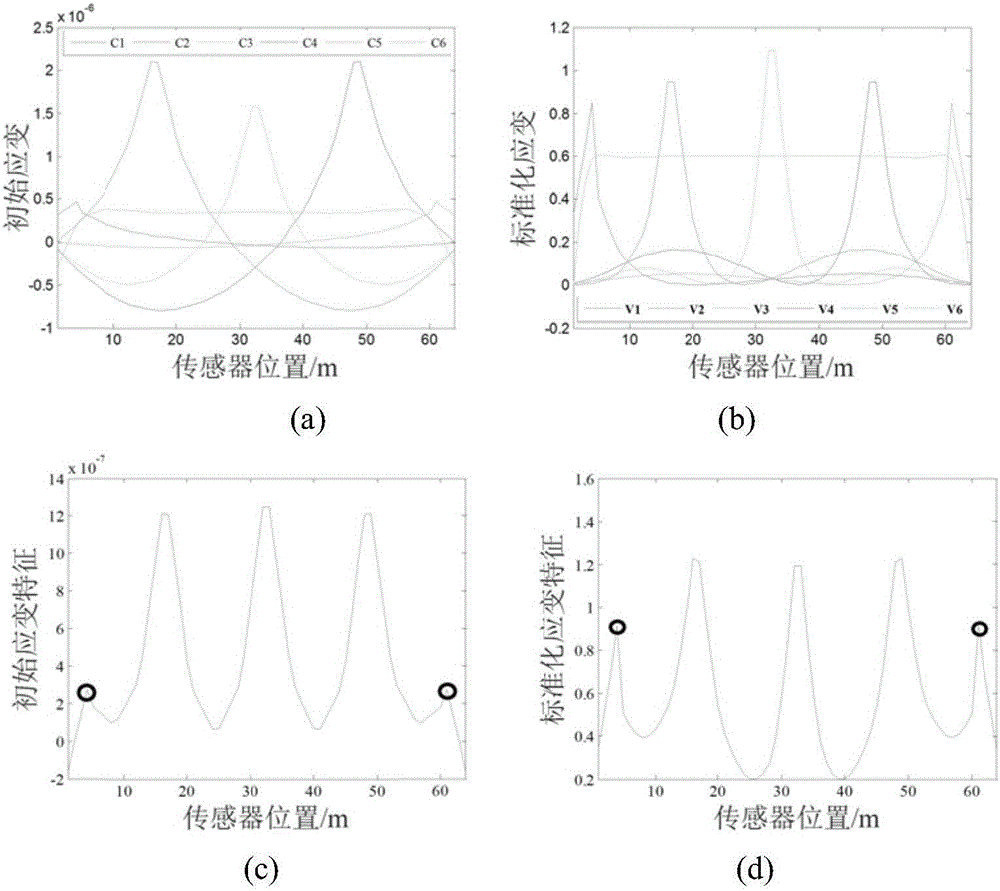

[0060] Step 1: Modeling by finite element method and analyzing the typical working conditions of daily loads. The six typical working conditions of the arch bridge are: the concentrated force acts on the two arch foot sections, the vault section, L / 4 and 3L / 4 Arch rib sections, and uniform load cases such as figure 2 shown. Obtain the bending strain curve C of the structure under each load condition i , i=1,2,3,4,5,6, such as image 3 (a) shown.

[0061] The second step: use formula (1) to normalize the six strain c...

Embodiment 2

[0079] Taking the sensor layout scheme of Sutong Bridge auxiliary channel bridge as an example, the concept of area sensing and how to select structural key components through vulnerability analysis and sensor layout based on the concept of area sensing are introduced. The auxiliary channel bridge of Sutong Bridge is a prestressed concrete continuous rigid frame bridge with three spans of 140 meters, 268 meters and 140 meters respectively. The main pier is an ordinary reinforced concrete double thin-walled rectangular hollow pier. The box girder is a single-box single-chamber cross-section, with a roof width of 16.4m, a floor width of 7.5m, a beam height of 15.0m at the root, and a beam height of 4.5m at the mid-span and side-span straight sections. The minimum thickness of the top plate in the box is 0.32m, the thickness of the web plate is 0.45-1.0m, and the thickness of the bottom plate is 0.32-1.7m. The total width of the bridge deck is 34m, with 6 lanes in both direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com