Method for indirectly measuring dry deposition velocity of PM2.5 on surface of plant

A PM2.5, dry sedimentation technology, applied in analytical materials, instruments, etc., can solve the problems of high experimental cost, small weighing, difficult operation, etc., to achieve simple and easy operation, reduce system errors, and experimental consumption. less time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment relates to an indirect measurement of plant surface PM 2.5 The method for dry sedimentation rate, it may further comprise the steps:

[0037] 1. PM for laboratory simulation 2.5 Granular preparation

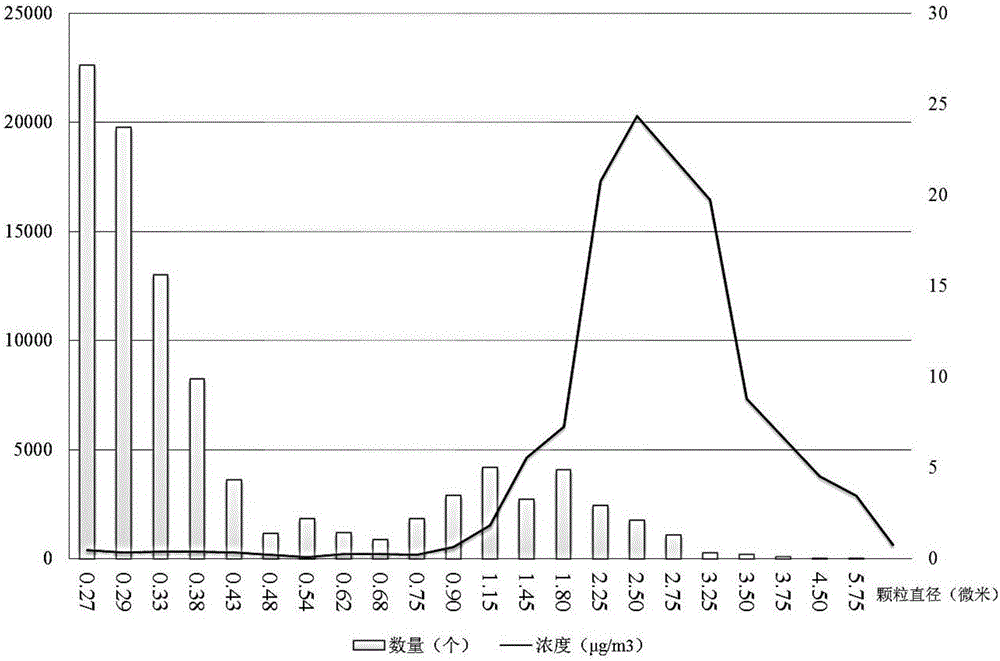

[0038] To ensure that laboratory simulations use PM 2.5 The particle size of the particles meets the test requirements. We conduct pre-tests on diamond powders with different particle sizes purchased in turn, and obtain diamond powders that meet the test requirements through the measurement of the Grimm1109 particle size spectrometer. Such as figure 1 As shown, the mass concentration of alternative diamond particles is mainly distributed at the particle diameter of 2.5 μm, which meets the test requirements.

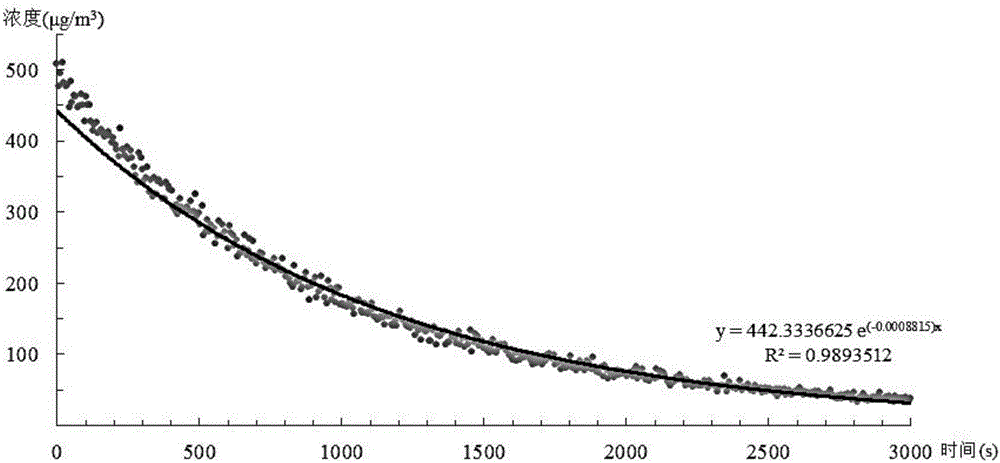

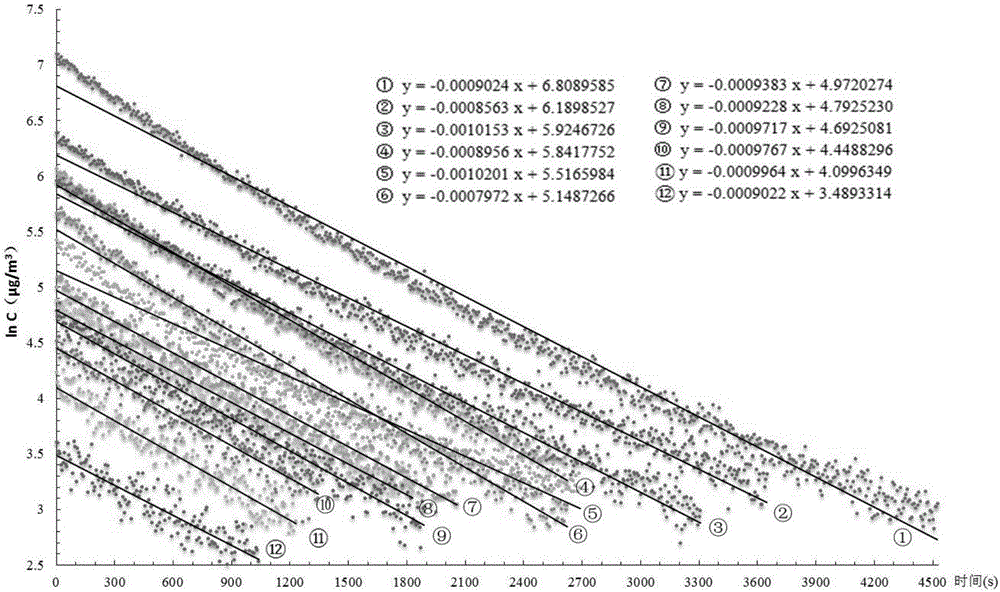

[0039] 2. PM for laboratory simulation 2.5 Determination of the concentration range of particulate matter and determination of the duration of the experiment

[0040] 2.1 PM for laboratory simulation 2.5 Determination of the concentration range of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com