Measurement device and characterization method for explosive temperature power reduction degree

A measuring device and technology for explosives, which are applied in directions such as material explosiveness, and can solve problems such as cumbersome calculation of the power attenuation of explosives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

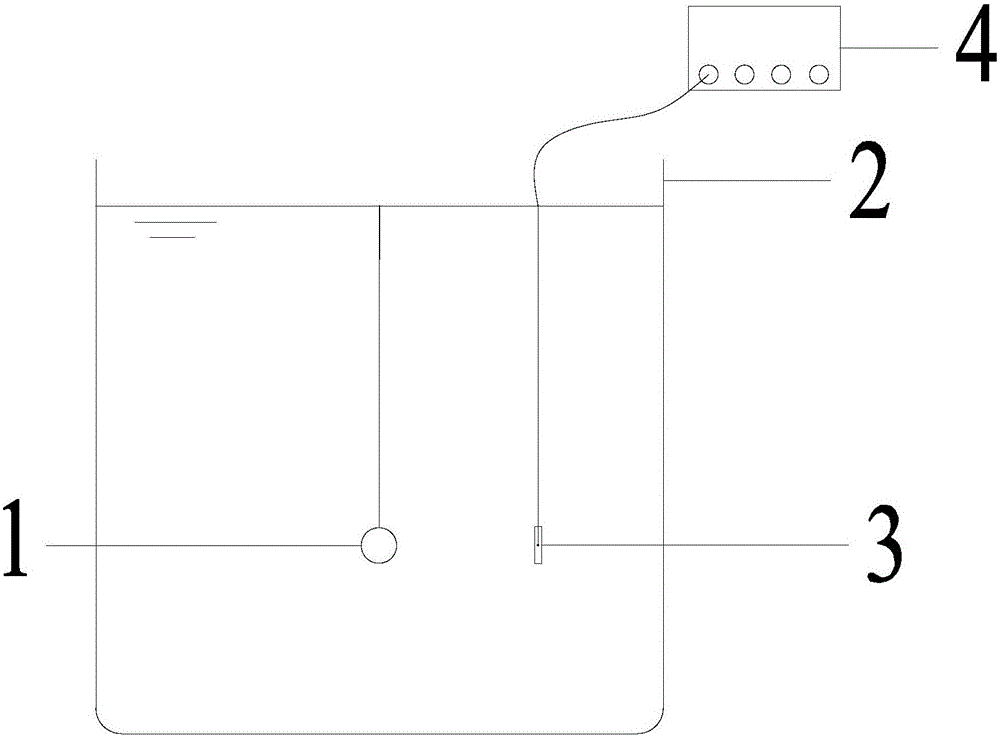

[0056] Such as figure 1 As shown, this embodiment provides a device for measuring the temperature reduction degree of explosives, which includes an explosive 1 , an underwater explosion tank 2 , a pressure sensor 3 and an oscilloscope 4 .

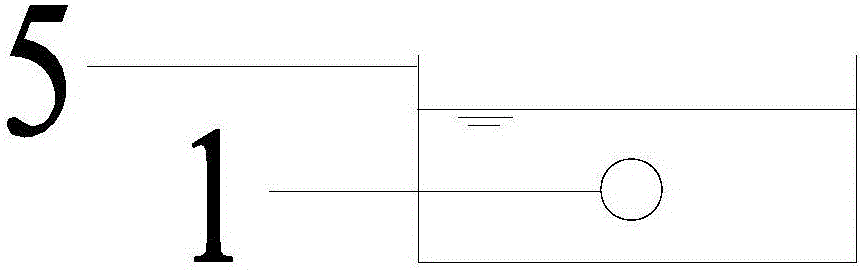

[0057] The explosive 1 is an emulsion explosive, which can be sensitized by a physical sensitizer or a chemical sensitizer, such as glass microspheres, perlite, NaNO 2 etc. It can be heated in a water bath after packaging, such as figure 2As shown, the explosive 1 is first placed in the water bath in the water bath thermostat 5 for heating, and then placed in the underwater explosion tank 2 after heating for a certain period of time; wherein, the water bath thermostat 5 can adjust the temperature of the water bath, and its temperature adjustment range is between room temperature and Between 100°C and the temperature control accuracy is 0.5°C, which is used to simulate the water bath environment of the powder roll in the high temperature b...

Embodiment 2

[0065] This embodiment provides a method for characterizing the temperature reduction degree of explosives, the method comprising the following steps:

[0066] Step 1, placing explosives of a certain quality in a water bath in a water bath incubator and heating for a certain period of time;

[0067] Step 2. Place the pressure sensor in the underwater explosion tank and connect it to an oscilloscope;

[0068] Step 3, placing the explosive heated in the water bath in the underwater explosion tank for detonation;

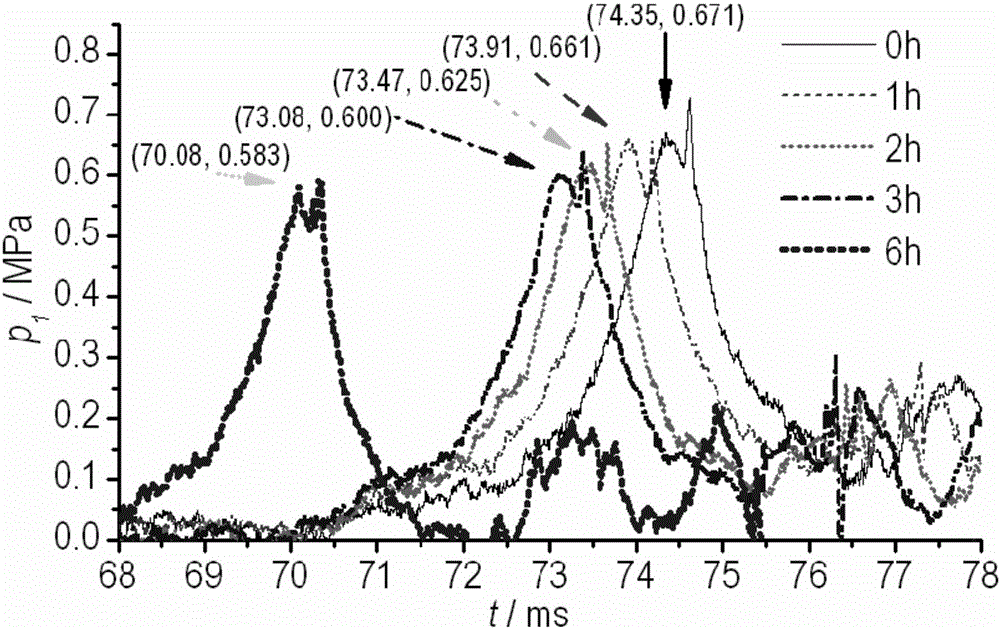

[0069] Step 4, measuring the pressure-time history curve through the pressure sensor and the oscilloscope;

[0070] Step 5, changing the quality of the explosive that has not been heated in a water bath to obtain the corresponding first bubble pulsation period;

[0071] Step 6, deduce the temperature reduction degree calculation formula according to the first bubble pulsation cycle, and calculate the temperature reduction degree after the explosive water bath heating...

Embodiment 3

[0086] The difference between this embodiment and embodiment 2 is: in step 6, the derivation process of the calculation formula of the temperature reduction degree is as follows:

[0087] 1) After the explosive explodes underwater, the period of the first bubble pulse is as follows:

[0088] T b = K · ρ 1 2 · ( W · Q ) 1 3 / P h 5 6

[0089] Among them, T b is the first bubble pulsation period, K is the coefficient, ρ is the liquid density, W is the mass of the explosive, Q is the detonation heat of the explosive, P k is the total water pressure at the explosion depth;

[0090] 2) order Rewrite the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com