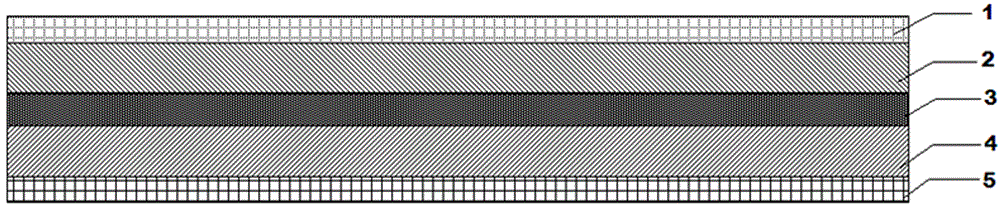

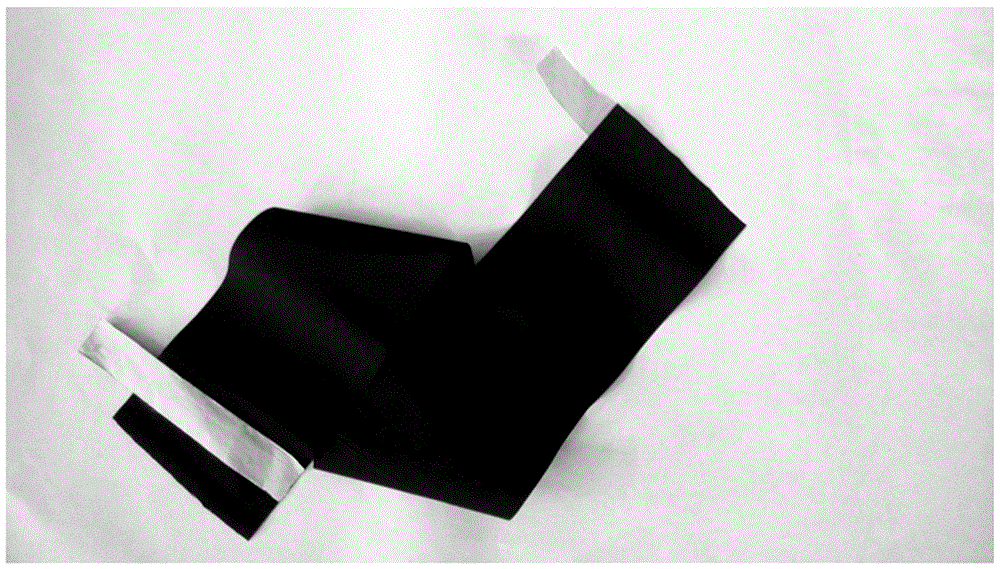

Flexible integrated thin-film lithium-sulfur or lithium ion battery cell, battery and preparation method thereof

A lithium-ion battery and cell technology, applied in the field of electrochemical energy storage, can solve the problems of poor flexibility, low bonding strength between the active material and the current collector interface, easy to fall off, etc., to achieve the effect of strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

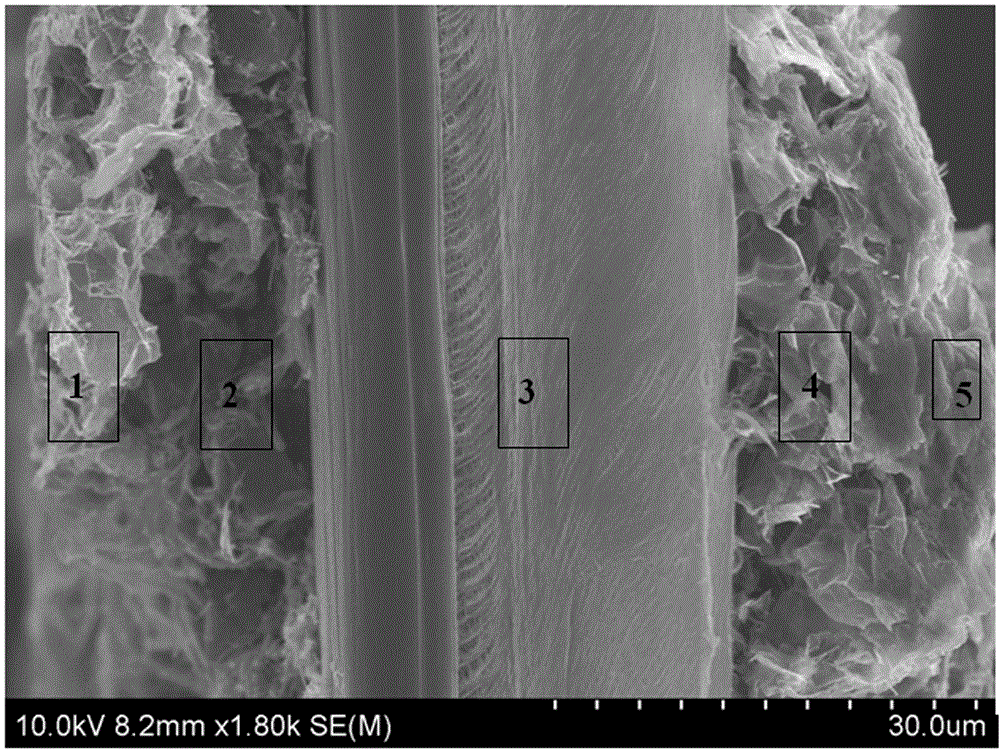

[0041] Weigh 0.5g PVDF and add it to 30g NMP (N-methylpyrrolidone), stir with a magnetic stirrer until the PVDF is completely dissolved; weigh 0.4g acetylene black and 0.1g carbon nanotubes into the PVDF solution, stir for 2 hours; weigh 4g The lithium-rich ternary material was added into the above dispersion liquid, and stirred for 8 hours to obtain the positive electrode slurry. The positive electrode slurry was scraped-coated on a polyethylene separator, and dried in an oven at 60°C.

[0042] Weigh 0.2g PVDF and place it in 30g NMP, and stir it with a magnetic stirrer until the PVDF is completely dissolved; weigh 0.15g SP, 0.1g VGCF, and 0.5g graphene and add it to the PVDF solution, and stir for 3 hours to obtain a conductive paste; The material is sprayed on the positive electrode coating, the tabs are pressed and bonded to the conductive paste, and dried in an oven at 90°C.

[0043] Weigh 0.4g CMC and add 20g deionized water and stir until CMC is completely dissolved; W...

Embodiment 2

[0048] Weigh 0.5g PVDF into 30g NMP, stir with a magnetic stirrer until PVDF is completely dissolved; weigh 0.4g SuperP and 0.1g VGCF into the PVDF solution, stir for 2h; weigh 4g carbon / sulfur composite material and add to the above dispersion , stirred for 8h to obtain positive electrode slurry. The positive electrode slurry was scraped-coated on a polyethylene separator, and dried in an oven at 60°C.

[0049] Weigh 0.3g PVDF and place it in 30g NMP, and stir it with a magnetic stirrer until the PVDF is completely dissolved; weigh 0.6gSP, 0.3g VGCF, and 0.1g graphene and add it to the PVDF solution, and stir for 3 hours to obtain a conductive paste; The material is sprayed on the positive electrode coating, the tabs are pressed and bonded to the conductive paste, and dried in an oven at 90°C.

[0050] In a drying room, weigh 0.5g of PVDF and add it to 20g of γ-butyrolactone and stir until the PVDF is completely dissolved; weigh 4g of surface-passivated lithium powder partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com