Estimation method of initial position of electrically excited synchronous motor rotor under vibration

A synchronous motor and rotor vibration technology, applied in the direction of motor generator control, electromechanical transmission control, electronic commutation motor control, etc., can solve the problem of reducing estimation accuracy, improve accuracy, reduce estimation error, and remove current noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0029] (1) Apply an excitation voltage to the rotor of an electrically excited synchronous motor.

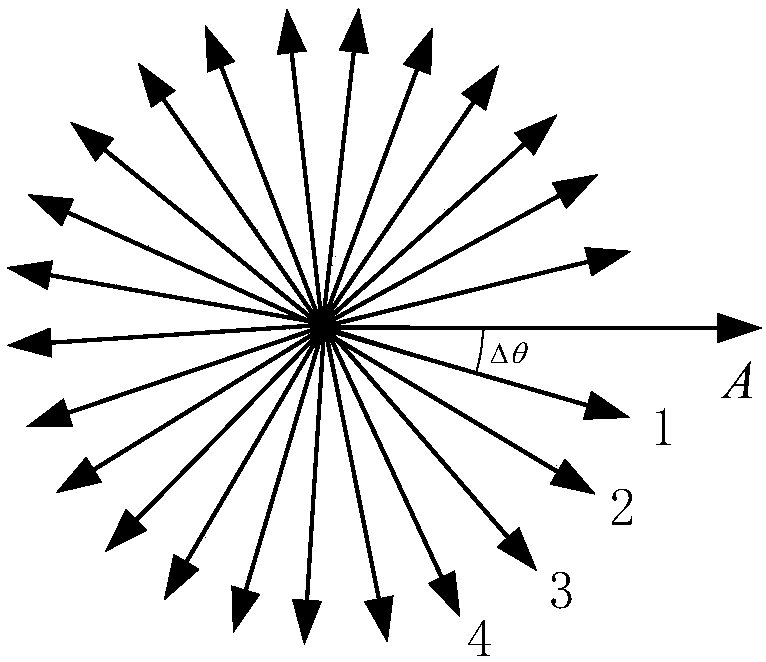

[0030] (2) if figure 1 As shown, a voltage space vector with a fixed amplitude is applied to the direction of phase A of the stator of the electrically excited synchronous motor, and the current acquisition value of the resolver is recorded Δ 0 .

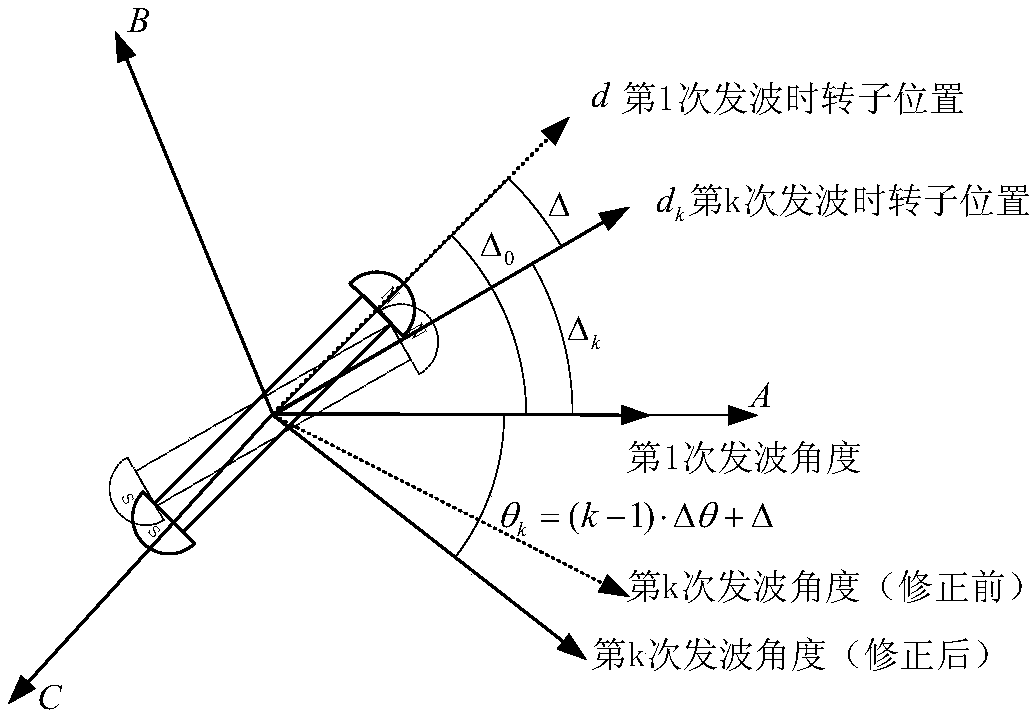

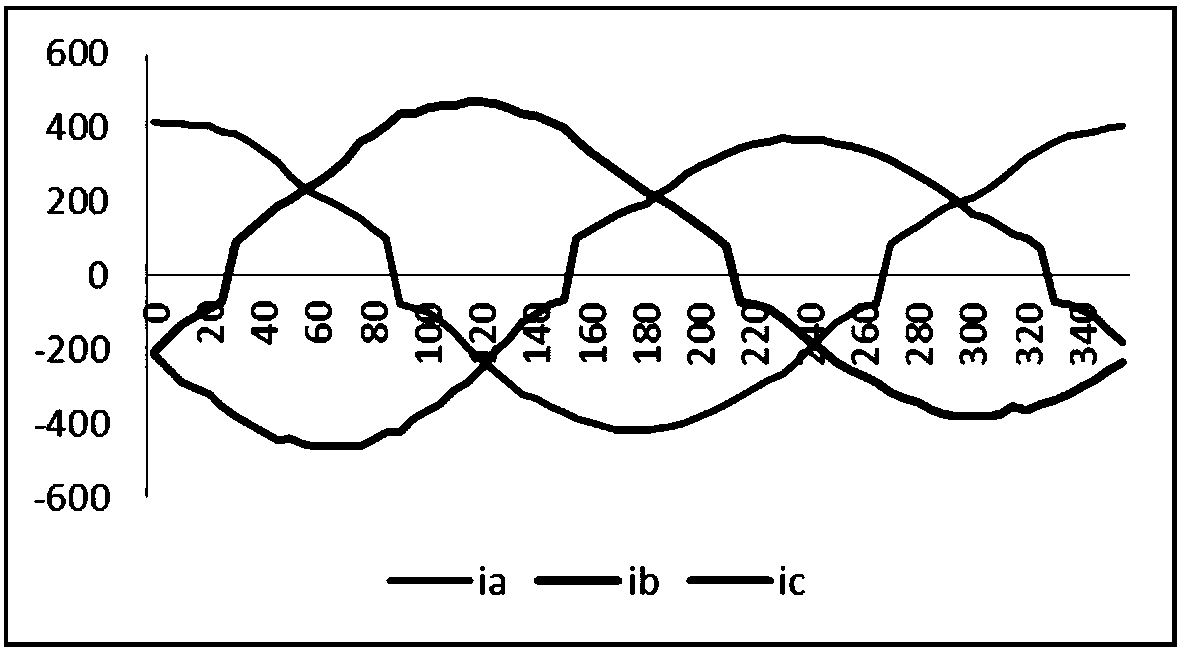

[0031] (3) Continuously apply a voltage vector with equal magnitude around the stator 360 electrical angles starting from phase A with Δθ as the step length. like figure 2 As shown, the θ is corrected before each wave k To ensure that the voltage space vector applied on the stator is distributed in a uniform electrical angle relative to the actual position of the rotor, the correction formula is as follows: when the response current on the stator drops to zero, record the current acquisition of the resolver before t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com