Processing technology capable of effectively keeping fresh taste of poultry meat

A processing technology and poultry technology, which is applied in poultry processing, meat processing, and preservation of meat/fish with a coating protection layer, etc. It can solve the problems of insufficient freezing of chicken cells, loss of nutrition and umami taste, and chicken sourness, etc., to achieve Buffer supply shortage or accumulation of excess supply, stable life management, and the effect of taste and nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

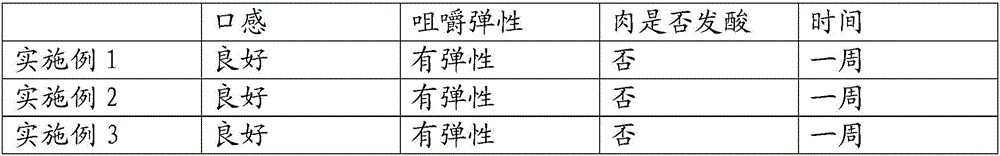

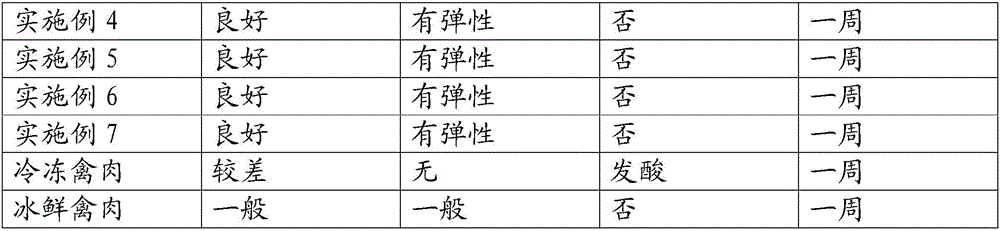

Examples

Embodiment 1

[0030] The processing technology that can effectively keep the fresh taste of poultry meat of the present embodiment comprises the following steps:

[0031] 1) Bleeding: cutting the throat of live poultry to ensure that the blood inside the poultry is cleaned;

[0032] 2), depilation: put the bled poultry in hot water to scald for depilation;

[0033] 3), ice water cooling: immerse the poultry carcass after depilation in ice water for cooling;

[0034] 4), evisceration: take out the viscera of the poultry, and sort the viscera;

[0035] 5) Rinse with ice water: use ice water to clean and cool the inner cavity and appearance of the poultry after evisceration;

[0036] 6), coating: according to the unsaturated fatty acid content of different poultry meat, spray preservative;

[0037] 7), packaging: vacuum packaging;

[0038] 8), liquid nitrogen quick-freezing: put the vacuum-packed poultry into the liquid nitrogen quick-freezing machine for quick-freezing;

[0039] 9) Stora...

Embodiment 2

[0048] The processing technology that can effectively keep the fresh taste of poultry meat in this embodiment is basically the same as in Embodiment 1, except that:

[0049]Step 2) Depilation: Set the temperature at 75°C according to the size of the poultry and the roughness of the skin, and control the depilation time at 120S. Step 3) Ice-water cooling: submerge the depilated poultry carcass in 4°C ice water and cool to 22°C. Step 5) Rinse with ice water: use 4°C ice water to clean and cool the inner cavity and appearance of the poultry after evisceration. Step 6) Film coating: according to the unsaturated fatty acid content of different poultry meat, spray a preservative with a concentration of 2.5%. Step 8) Quick-freezing with liquid nitrogen: Set the quick-freezing temperature at -120°C according to the size of the poultry and the thickness of the packaging film. The quick-freezing time is controlled within 30 minutes, and the size of the ice crystals formed by quick-free...

Embodiment 3

[0051] The processing technology that can effectively keep the fresh taste of poultry meat in this embodiment is basically the same as in Embodiment 1, except that:

[0052] Step 2) Depilation: Set the temperature at 70°C according to the size of the poultry and the roughness of the skin, and control the depilation time at 100 seconds. Step 3) Ice-water cooling: submerge the depilated poultry carcass in 2°C ice water and cool to 20°C. Step 5) Rinse with ice water: use 3°C ice water to clean and cool the inner cavity and appearance of the poultry after evisceration. Step 6) Film coating: according to the unsaturated fatty acid content of different poultry meat, spray a preservative with a concentration of 2.1%. Step 8) Quick-freezing with liquid nitrogen: Set the quick-freezing temperature at -90°C according to the size of the poultry and the thickness of the packaging film, and control the quick-freezing time within 30 minutes. The size of the ice crystals formed by quick-fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com