Moistureproof sugar powder for baking

A baking and powdered sugar technology, which is applied in the field of moisture-proof powdered sugar for baking, can solve the problems of low starch taste and affect the taste and flavor of powdered sugar, and achieve the effect of excellent taste, stable properties and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

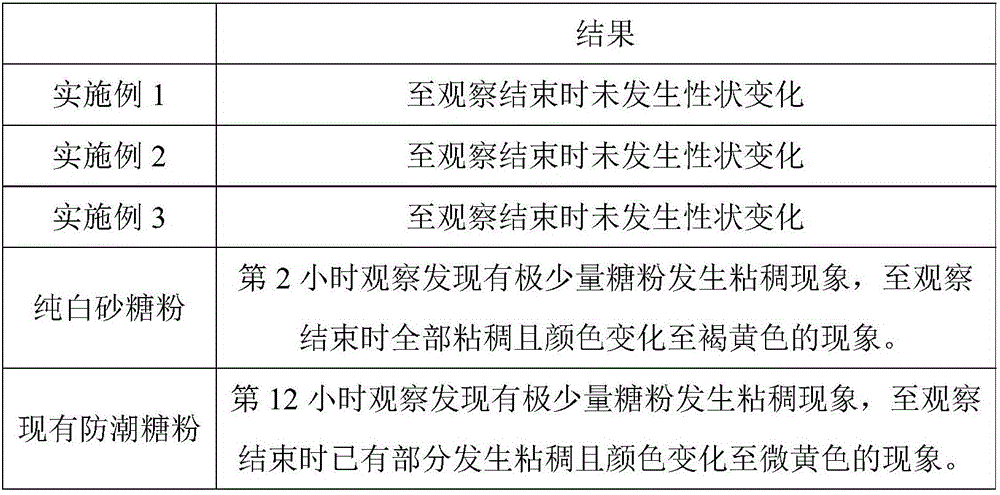

Examples

Embodiment 1

[0035] A moisture-proof powdered sugar for baking, comprising the following raw materials in parts by weight: white sugar powder 63, additive powder 37;

[0036] The additive powder includes the following raw materials in parts by weight: glucose syrup 58, palm oil 27, anhydrous butter 9, lactose 5.95, calcium silicate 0.05.

[0037] The preparation method of the above-mentioned moisture-proof powdered sugar for baking comprises the following steps:

[0038] (1) Ingredients

[0039] Fully blend palm oil and anhydrous butter in No. 1 tank at 65°C to obtain mixture A;

[0040] Dry mix lactose and calcium silicate evenly at normal temperature and then preliminarily mix with one-third of the glucose syrup in a small mixing tank, then mix the resulting mixture with the remaining glucose syrup in No. 2 tank, and Stir evenly under the condition of 65°C to obtain mixture B;

[0041] Pour mixture A and mixture B into the mixing tank at the same time, raise the temperature to 78°C, a...

Embodiment 2

[0053] A moisture-proof powdered sugar for baking, comprising the following raw materials in parts by weight: white sugar powder 60, additive powder 34;

[0054] The additive powder includes the following raw materials in parts by weight: glucose syrup 55, palm oil 25, anhydrous butter 7, lactose 5.85, calcium silicate 0.03.

[0055] The preparation method of the above-mentioned moisture-proof powdered sugar for baking comprises the following steps:

[0056] (1) Ingredients

[0057] Fully blend palm oil and anhydrous butter in No. 1 tank at 60°C to obtain mixture A;

[0058] Dry mix lactose and calcium silicate evenly at normal temperature and then preliminarily mix with one-third of the glucose syrup in a small mixing tank, then mix the resulting mixture with the remaining glucose syrup in No. 2 tank, and Stir evenly at 60°C to obtain mixture B;

[0059] Pour mixture A and mixture B into the mixing tank at the same time, raise the temperature to 73°C, and keep it at a spee...

Embodiment 3

[0071] A moisture-proof powdered sugar for baking, comprising the following raw materials in parts by weight: white sugar powder 66, additive powder 40;

[0072] The additive powder includes the following raw materials in parts by weight: glucose syrup 61, palm oil 29, anhydrous butter 11, lactose 6.05, calcium silicate 0.07.

[0073] The preparation method of the above-mentioned moisture-proof powdered sugar for baking comprises the following steps:

[0074] (1) Ingredients

[0075] Fully blend palm oil and anhydrous butter in No. 1 tank at 70°C to obtain mixture A;

[0076] Dry mix lactose and calcium silicate evenly at normal temperature and then preliminarily mix with one-third of the glucose syrup in a small mixing tank, then mix the resulting mixture with the remaining glucose syrup in No. 2 tank, and Stir evenly at 70°C to obtain mixture B;

[0077] Pour mixture A and mixture B into the mixing tank at the same time, raise the temperature to 83°C, and keep it at a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com