Ginseng manufacturing method using a high-temperature/high-pressure

A high-temperature, high-pressure technology, applied in the field of preparation of red ginseng, can solve the problems of unmaintainable shape, blackening, cracking, etc., and achieve the effects of preventing browning of color, increasing content, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

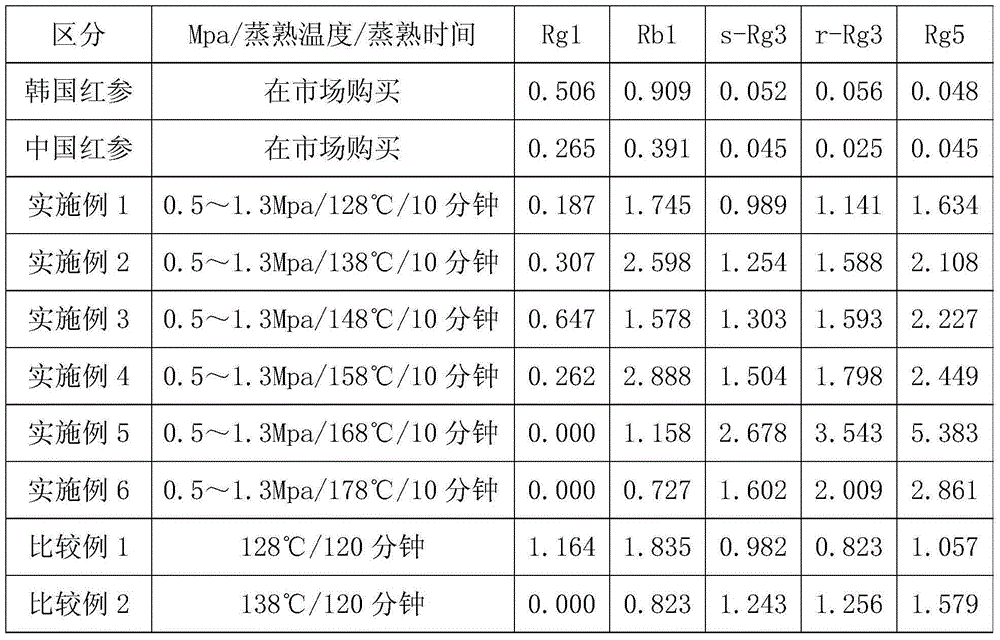

Embodiment 1

[0088] Purchase 20 (6-year-old roots) (100 parts by weight) fresh ginseng at the Geumsan market in Korea, and after washing in a drum washing machine, precipitate in water for 24 hours together with schisandra chinensis (50 parts by weight). Take out the precipitated ginseng and put it into a high-temperature and high-pressure steamer, and steam it at a temperature of 128°C for 120 minutes. At this time, when the temperature reaches 100°C, start the pressurizing device. , and pressurized for 10 minutes with a pressure range of 0.5-1.3Mpa. The steamed processed ginseng was put into a hot air dryer, and dried at a temperature range of 50-55° C. for 48 hours, thereby preparing processed ginseng with a water content of about 14%.

Embodiment 2

[0090]20 (6-year-old roots) (100 parts by weight) fresh ginseng were purchased from Geumsan Market, Korea, and after washing in a drum washing machine, they were precipitated in water together with Schisandra chinensis (50 parts by weight) for 24 hours. Take out the precipitated ginseng and put it into the high-temperature and high-pressure steamer, and steam it at 138°C for 120 minutes. At this time, when the temperature reaches 100°C, start the pressurizing device, At this time, the pressure was applied for 10 minutes with a pressure range of 0.5-1.3Mpa. The steamed processed ginseng was put into a hot air dryer, and dried at a temperature range of 50-55° C. for 48 hours, thereby preparing processed ginseng with a water content of about 14%.

Embodiment 3

[0092] Purchase 20 (6-year-old roots) (100 parts by weight) fresh ginseng at the Geumsan market in Korea, and after washing in a drum washing machine, precipitate in water for 24 hours together with schisandra chinensis (50 parts by weight). Take out the precipitated ginseng and put it into a high-temperature and high-pressure steamer, and steam it at a temperature of 148°C for 120 minutes. At this time, when the temperature reaches 100°C, start the pressurizing device. , and pressurized for 10 minutes with a pressure range of 0.5-1.3Mpa. The steamed processed ginseng was put into a hot air dryer, and dried at a temperature range of 50-55° C. for 48 hours, thereby preparing processed ginseng with a water content of about 14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com